I. Advantages TT Earthing System

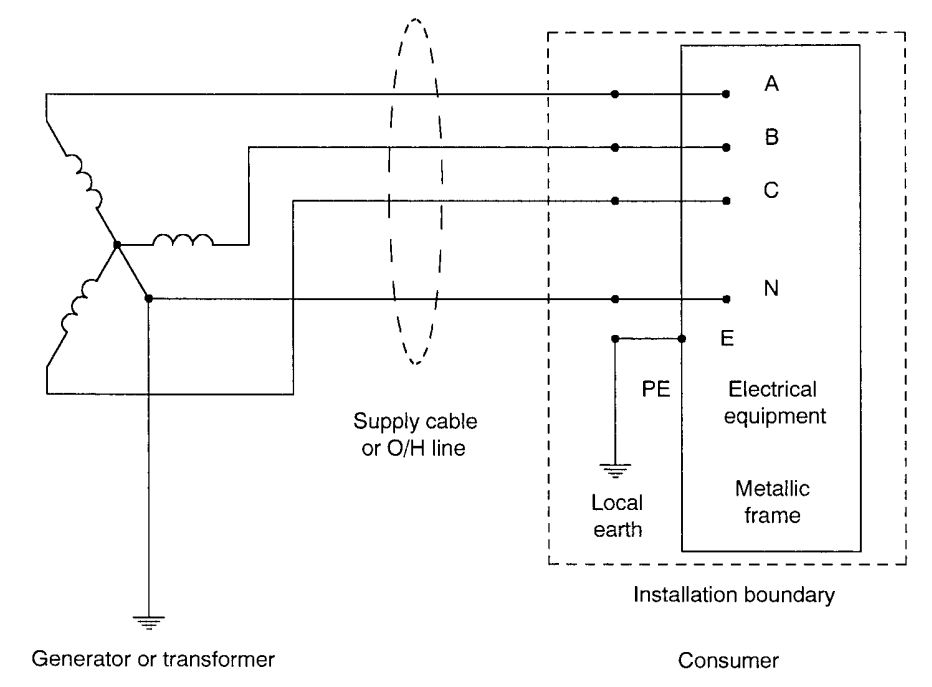

Reduced Fault Current Impact on the Supply Network. In a TT system, the earth fault current primarily flows through the local earth electrode, minimizing the effect on the supply network. In contrast, TN systems may return fault currents through the supply neutral, impacting the entire system.

Improved Electrical Safety. The TT system is less likely to experience dangerous voltages caused by a broken neutral in the supply network, as the neutral and protective earth are separate. Each installation has its own earth electrode, reducing the likelihood of shared faults.

Simple Installation and Lower Cost for Isolated Locations. TT systems are often simpler and more cost-effective to install, especially in rural or isolated areas where establishing a reliable connection to a TN network might be expensive or impractical.

Independent of Utility Earth. TT systems rely on a local earthing electrode, making them independent of the utility's earthing arrangements. This is beneficial in areas with unreliable or variable supply earthing conditions.

Effective in High-Resistivity Soils. TT systems can be tailored with advanced earthing designs (e.g., multiple electrodes, chemical treatment) to mitigate the challenges of high-resistivity soils, ensuring good earthing performance.

Reduced Risk of Circulating Currents. Unlike TN systems, where shared protective conductors might allow circulating currents, TT systems avoid this issue due to their separate earthing arrangements.

II. Applications of the TT Earthing System

- Rural and Isolated Areas. Commonly used where utility companies do not provide a TN-C-S (combined neutral and earth) connection, such as remote villages and farms.

- Industrial Facilities with High Safety Requirements. Often employed in chemical plants, oil refineries, and other industries where additional safety against electrical faults is critical.

- Renewable Energy Installations. Frequently used in solar farms, wind farms, and other renewable energy systems due to their isolated nature and independence from the utility's earthing system.

- Sensitive Installations. Data centers, hospitals, and laboratories may use TT systems to minimize interference and ensure independent, localized fault handling.

- Temporary Installations. Used for temporary power supplies, such as in construction sites, exhibitions, and outdoor events, where establishing a TN system is not practical.

- Residential and Commercial Buildings in Specific Regions. Adopted in countries where TT systems are the standard practice due to local regulations or soil conditions.

In summary, the TT earthing system is particularly advantageous in situations where safety, independence from utility earthing, and adaptability to local conditions are prioritized.

III. Tabulated Comparison

Here’s a tabular comparison of the TT and TN earthing systems:

| Feature | TT Earthing System | TN Earthing System |

|---|---|---|

| Definition | Local earth electrode provides the protective earth. | Protective earth connected to the utility's neutral. |

| Fault Current Path | Fault current flows through the local earth electrode. | Fault current returns through the supply neutral. |

| Impact of Broken Neutral | Minimal, as protective earth is independent of the supply. | High risk; broken neutral can lead to dangerous voltages. |

| Safety | High safety due to independence from utility earthing. | Safety depends on proper connection to the supply neutral. |

| Installation Cost | Lower in isolated or rural areas. | Higher, as it requires extensive conductor network. |

| Dependence on Utility | Independent of the utility's earthing arrangement. | Dependent on the utility's neutral and earthing. |

| Fault Current Magnitude | Lower, as the earth electrode's resistance limits it. | Higher, as the return path is through the supply network. |

| Circulating Currents | None, as protective earth is localized. | Possible, due to shared protective and neutral conductors. |

| Applications | Rural areas, temporary sites, renewable energy installations, sensitive facilities. | Urban areas, industrial and commercial buildings with reliable supply. |

| Adaptability to Soil | Can be optimized for high-resistivity soils using advanced earthing methods. | May face challenges in high-resistivity soils without utility support. |

This table highlights the strengths of each system, showing that the choice depends on the application, location, and local regulations.