Application

Flame retardant cables and fire resistant cables are both designed to withstand specific fire-related hazards, but they serve different primary purposes.

Flame retardant cables are designed to prevent the spread of fire to new areas. The primary goal is to prevent a fire from being propagated along the length of the cable. These cables are typically used in buildings or installations where the spread of fire needs to be minimized, like residential or commercial buildings.

Fire resistant cables are designed to maintain circuit integrity and continue to function during a fire. The aim is to ensure that critical safety systems remain operational during a fire (e.g., alarm systems, sprinkler systems, and emergency lighting). These cables are used in critical safety systems like alarm circuits, fireman's elevators, or any other application where it is crucial for the circuit to maintain operation during a fire, such as in escape route lighting or certain control circuits.

Construction

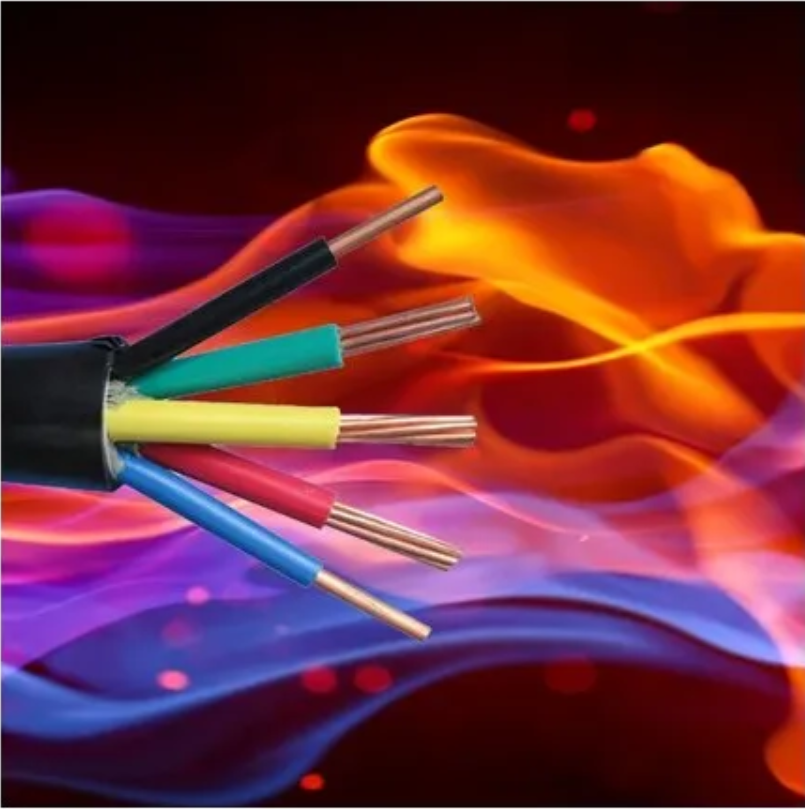

Flame retardant cables are designed to resist the propagation of flames along the cable's length when exposed to a fire. These cables are formulated with materials that can resist catching fire easily and will not support combustion. Flame retardant cables are often used to reduce the risk of a fire starting or spreading due to electrical faults or external factors. Flame retardant cables have compounds added to the outer jacket and sometimes to the insulation within the cable that prevent the propagation of flames. These compounds halt the spread of fire along the cable.

Fire-resistant cables are engineered to maintain their functionality and continue carrying electrical signals during a fire. These cables are constructed using special materials that can withstand higher temperatures and maintain their structural integrity even in the presence of flames. Fire-resistant cables are designed to provide uninterrupted power and communication services in critical areas during a fire, allowing emergency systems to operate and aiding in safe evacuation. Fire resistant cables are constructed in a way to withstand high temperatures. This might involve using materials like mica or other special compounds that can keep the conductors insulated even when exposed to fire.

International Standards

- IEC 60332-1: Tests on electric and optical fibre cables under fire conditions - Part 1: Test for vertical flame propagation for a single insulated wire or cable.

- IEC 60332-3: Tests on electric cables under fire conditions - Part 3: Tests for vertical flame spread of vertically-mounted bunched wires or cables.

- IEC 60331: Tests for electric cables under fire conditions - Circuit integrity. There are several parts to this standard, depending on the specific type and application of the cable.

- IEC 60754-1 & IEC 60754-2: Test on gases evolved during combustion of materials from cables – Parts 1 & 2 respectively.

- BS EN 50265 & BS EN 50266: Tests on electric and optical fibre cables under fire conditions - Test for vertical flame propagation.

- BS 6387: Specification for performance requirements for cables required to maintain circuit integrity under fire conditions. The test examines three criteria: exposure to flame (C), exposure to water (W), and exposure to mechanical shocks (Z).

- EN 50575: Power, control and communication cables - Cables for general applications in construction works subject to reaction to fire requirements.

- IEEE 1202: This standard tests flame propagation and smoke generation characteristics of electrical and optical-fiber cables used in power and control circuits. It's often referenced for cables used in transit systems.

- IEEE 1580: A standard for marine shipboard cable, it incorporates flame resistance tests in addition to other specifications to ensure the cable's functionality and safety onboard ships.

- IEEE 383: This standard focuses on the flame testing of cables used in nuclear power generating stations. Given the critical nature of such environments, the cables must perform to a high standard, and this includes flame retardancy.