What is Skin Effect?

The skin effect refers to the tendency of an alternating current (AC) to become distributed non-uniformly within a conductor, such that the current density is higher near the surface of the conductor and decreases at greater depths within the conductor. This effect is more pronounced at higher frequencies.

At lower frequencies, the skin effect is negligible, and the current distribution is relatively uniform across the conductor's cross-section. However, as the frequency increases, the skin effect becomes more pronounced. The higher-frequency components of the alternating current tend to flow near the surface of the conductor, while the lower-frequency components penetrate deeper into the conductor.

Results of Skin Effect

Effective Conductor Resistance Increases: Since the current is concentrated near the surface, the effective resistance of the conductor increases. This increased resistance results in more power dissipation as heat, which can limit the current-carrying capacity of the conductor.

Reduced Usable Conductor Cross-Sectional Area: At higher frequencies, the current tends to flow through a smaller effective cross-sectional area of the conductor due to the skin effect. As a result, the usable cross-sectional area for current flow is reduced, leading to a decrease in the conductor's effective current-carrying capacity.

Increased Power Losses: The concentration of current near the surface of the conductor leads to increased power losses in the form of heat. This can result in higher operating temperatures for the conductor, potentially exceeding safe limits and reducing its overall current-carrying capacity.

Mitigation of Skin Effect

Mitigating the effects of skin effect is crucial in various electrical applications, especially at higher frequencies where it becomes more pronounced. Here are several strategies commonly employed to mitigate skin effect:

Litz Wire: Litz wire is a type of multistrand wire consisting of individually insulated strands twisted or woven together. Each strand carries a portion of the total current, effectively increasing the surface area available for current flow. Litz wire reduces skin effect losses and is commonly used in high-frequency applications such as transformers, inductors, and RF antennas.

Hollow Conductors: By hollowing out the center of a conductor, the effective surface area available for current flow increases, reducing the impact of skin effect. This technique is particularly effective at higher frequencies.

Stranded Conductors: Using stranded conductors instead of solid conductors increases the surface area available for current flow. Stranded conductors are more flexible and have lower skin effect losses compared to solid conductors of the same total cross-sectional area.

Surface Treatment: Surface treatments such as plating or coating conductors with highly conductive materials (e.g., silver, gold, or copper) can reduce surface resistance and mitigate skin effect losses. These treatments help to maintain a more uniform current distribution across the conductor's cross-section.

Frequency Reduction: Lowering the operating frequency of the system reduces the impact of skin effect. However, this approach may not always be feasible, especially in applications where high frequencies are required.

Conductor Shape Optimization: Certain conductor shapes, such as rectangular or hollow conductors with wide surfaces perpendicular to the magnetic field, can help reduce skin effect losses by providing more surface area for current flow.

Skin Depth Reduction: Skin depth refers to the depth at which the current density decreases to a certain fraction of its value at the surface of the conductor. Using conductive materials with higher resistivity or lower permeability can reduce skin depth and mitigate skin effect losses.

Operating at Lower Temperatures: Skin effect losses increase with conductor temperature. Operating conductors at lower temperatures can help mitigate skin effect losses, although this may require enhanced cooling mechanisms.

Transmission Line Design: For high-frequency transmission lines, special designs such as coaxial cables or waveguides can minimize skin effect losses by confining the electromagnetic fields closer to the conductor surface.

Calculation of Derating Factor due to Skin Effect

Skin effect derating factor can be calculated using the formula provided in IEC 60287-1-1

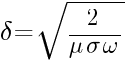

The skin depth (δ) can be calculated using the following formula:

Where:

μ is the permeability of the material (in henries per meter, H/m).

δ is the conductivity of the material (in siemens per meter, S/m).

ω is the angular frequency of the current (in radians per second, rad/s).

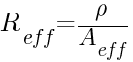

Once you've determined the skin depth, you can calculate the effective resistance (Reff) due to skin effect using:

Where:

ρ is the resistivity of the material (in ohm-meters, Ω·m).

Aeff is the effective cross-sectional area available for current flow.

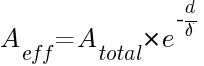

The effective cross-sectional area Aeff can be calculated as the total cross-sectional area (Atotal) multiplied by the skin depth (δ):

Where:

d is the depth from the surface of the conductor.

Keep in mind that the actual calculation and application of skin effect in engineering scenarios can vary based on the specific geometry of the conductor, the frequency of the AC current, and other factors. Advanced simulations or empirical data may be necessary for precise calculations in practical situations.