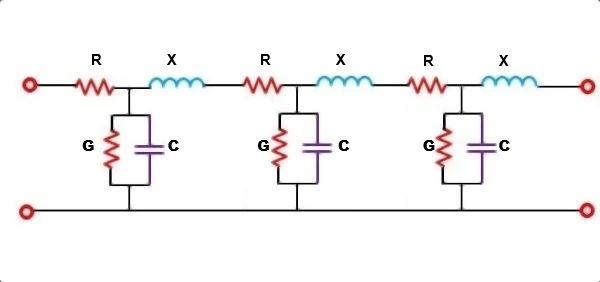

Every cable has, apart from its resistance, certain inductance and capacitance. The inductance and capacitance is roughly equally distributed along the cable length. Inductance L and capacitance C in a circuit create a resonance.

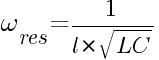

The formula for cable resonance is

Where:

ω = cable resonance frequency

l = cable length

L = cable inductance

C = cable capacitance

From the above equation, short cable lengths have higher resonance frequency which do not have an issue for the variable frequency drive (VFD) inverter. Longer cables, however, have lower resonance frequency which is within the VFD inverter bandwith. The cable resonance frequency can be excited after every switching instant. This condition creates additional stress on the cable, additional inverter current to charge and discharge the cable capacitance as well as increased peak voltage at the motor terminals.

The inverter voltage is basically amplified in the resonance condition so that motor insulation system will experience an increased voltage peaks. Those peaks, when present over longer period of time, may lead to increased partial discharge activities and accelerated aging of the motor insulation.

To mitigate the effect of cable resonance, a dv/dt filter is installed at the inverter output. The filter reduces the dv/dt at the converter output making it more motor friendly. Moreover, the dv/dt filter is a low-pass filter and as such provides damping of higher frequencies. Depending on the design of dv/dt filter, certain standard motor cable length is allowed.

A good example of long cables are those used for Electrical Submersible Pumps (ESPs). ESP cables lengths at some instances reached three (3) kilometers or even longer. In this case, necessary output filters shall be provided at the VFD output.