Definition

Sub-synchronous torsional interaction (SSTI) is a phenomenon in power systems where mechanical torsional oscillations of a turbine-generator shaft interact with the electrical sub-synchronous frequency components of the power system. This interaction can lead to detrimental effects on the stability and performance of the power system.

Sub-synchronous torsional interaction, a phenomenon that can occur in certain types of rotating machinery, such as turbines or generators, where the torsional natural frequency of the system is close to a subharmonic (fractional multiple) of the electrical system frequency. This interaction can lead to torsional vibrations that can affect the mechanical integrity of the equipment.

When the torsional natural frequency of a rotating system is close to a subharmonic of the electrical system frequency, it can lead to a phenomenon called sub-synchronous torsional interaction. This interaction can result in excessive torsional vibrations, potentially causing damage to the rotating machinery.

Subsynchronous torsional interaction (SSTI) also affects flexible AC transmission system (FACTS) devices as well as high voltage direct current (HVDC) transmission link with line-commutated current source converters (LCC).

Key Components

Key components of Sub-synchronous torsional interaction (SSTI) are

- Torsional Oscillations

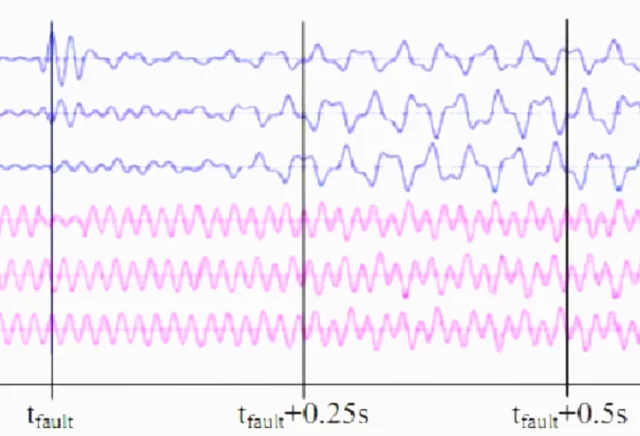

- These are oscillations or vibrations that occur in the mechanical shaft of a turbine-generator unit. Torsional oscillations are a result of the interaction between the mechanical inertia of the rotating masses and the stiffness of the shaft.

- Torsional vibrations involve twisting or rotational oscillations in the shafts of rotating machinery. These vibrations can occur due to variations in torque along the shaft's length.

- Sub-Synchronous Frequency Components

- In power systems, the synchronous frequency is the frequency at which the generators rotate, typically 50 or 60 Hz. Sub-synchronous frequencies are electrical frequencies that are below the synchronous frequency. Sub-synchronous frequencies can be caused by different factors, such as interactions with series compensated transmission lines or resonance conditions in the power system.

- In the context of electrical systems, the term "sub-synchronous" refers to a frequency that is less than the electrical system frequency. For example, if the electrical system operates at 60 Hz, a sub-synchronous frequency could be something like 59 Hz.

- Torsional Natural Frequency

- Every mechanical system has natural frequencies at which it tends to vibrate. The torsional natural frequency is the frequency at which the system naturally wants to oscillate in a torsional manner.

Effects of Sub-synchronous Torsional Interaction

When sub-synchronous frequencies coincide with the natural torsional frequencies of the turbine-generator shaft, sub-synchronous torsional interaction occurs. This interaction can lead to increased torsional stress on the shaft, potentially causing damage to the mechanical components of the generator.

The effects of sub-synchronous torsional interaction may include:

- Fatigue and damage

- The repeated stress caused by the interaction can lead to fatigue and damage of the turbine-generator shaft and associated components.

- Reduced operational life

- Continuous exposure to sub-synchronous torsional interaction may reduce the operational life of the generator.

- Instability

- The interaction can contribute to instability in the power system, leading to oscillations and potential cascading failures.

Mitigation of Sub-synchronous Torsional Interaction

To prevent or mitigate sub-synchronous torsional interaction, engineers use various techniques such as adjusting the system parameters, employing torsional dampers, or implementing control strategies to ensure that the natural frequencies do not coincide with subharmonics of the electrical system frequency. It's a complex area of study and requires careful analysis and design to ensure the reliable and safe operation of rotating machinery.

To mitigate sub-synchronous torsional interaction, power system engineers use various methods such as:

- Torsional Analysis

- Conducting a thorough analysis of the mechanical system to identify the natural torsional frequencies.

- Damping Systems

- Implementing damping systems to absorb and dissipate excess energy from torsional oscillations.

- Control Strategies

- Implementing control strategies to suppress unwanted torsional oscillations.

- System Design

- Ensuring that the design of the power system components takes into account potential torsional interactions.

Addressing sub-synchronous torsional interaction is crucial to maintaining the reliability and stability of power systems, especially in situations where the power system includes components with different characteristics and where resonance conditions may occur.

International Standards

There are standards related to sub-synchronous torsional prepared by the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE) provided standards that are relevant to power system dynamics and torsional interaction.

- IEC Standards

- IEC 60034-17: This standard provides guidelines for the determination of the torsional natural frequencies of rotating electrical machines.

- IEC 60909: It deals with short-circuit currents in three-phase a.c. systems.

- IEEE Standards

- IEEE Std 115: This standard provides guidelines for the testing and performance of synchronous generators in power plants, including aspects related to torsional interaction.

- IEEE Std 399: It provides guidelines for the design and installation of synchronous generators, and it may include considerations for torsional effects.

It's important to note that while these standards provide guidelines and recommendations, they may not explicitly address sub-synchronous torsional interaction. Engineers and professionals involved in the design and operation of power systems often use a combination of relevant standards and engineering best practices to address specific issues, such as sub-synchronous torsional interaction.