Electrical Engineers must ensure when designing generator systems that generators and the electrical loads are appropriate for the particular application. Standby power for health care facilities or prime power for industrial plants, electrical engineers must decide on generator rating, load types, multiple generators requirement, fuel storage, switching scenarios, and other criteria to satisfy the requirement of the project.

Electrical engineers should ensure that the generators and the electrical distribution systems are reliable and effective in providing power to the critical loads. The requirement for generator systems are usually provided in building codes. Non-emergency loads that require backup power shall also be identified. When the loads require increased reliability, a paralleled generating system complete with electrical paralleling switchgear are required.

Power interruptions, even for a short duration, can be a potential hazard to public health and safety. Extreme weather and other natural disasters likewise often disrupt power even for days. When these situations occur, they call attention to the vulnerability of the nation’s electrical grid and the importance of alternatives. Hospitals, airports, data centers, water and sewage facilities, fueling stations, communication, and transportation systems require alternate-power sources to limit the impact and ultimately save lives during times of crisis. The loss of electrical power due to storms, natural disasters, or high-power-demand issues are increasingly common. The loss of business and the associated economic impact from power outages are significant. Emergency generators are necessary to provide the reliable power required to maintain operations during primary supply system failures.

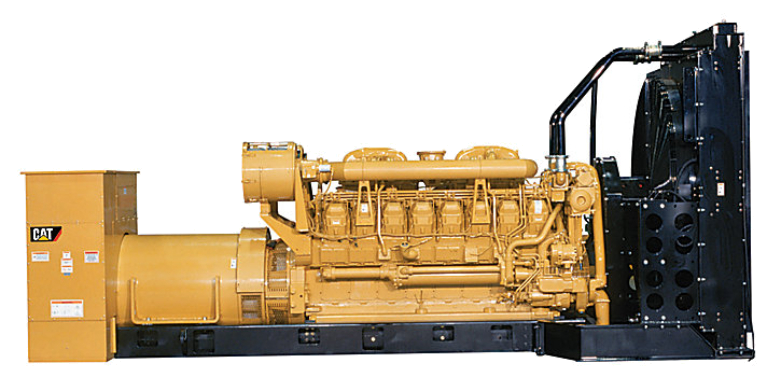

Preference for Diesel-powered Generators

Diesel-powered generators are considered among the most reliable approaches to providing backup power. When compared with alternative fuels and technologies, diesel-powered generators provide a steady supply of high-quality power and superior performance for transient or fluctuating power demands due to the high-torque characteristics of diesel engines.Diesel generators have rapid response time, good load-carrying capacity, easy avialability of fuel and excellent reliability. Diesel-powered generators quick response time can provide power to critical loads within seconds of normal source-power failure. In hospitals and critical care facilities standby power systems need to start automatically and run at full capacity within 10 seconds of power failure. Diesel generators are available in a range of sizes to meet facility power needs.

Paralleling Generator Systems

Paralleling is the operation where multiple power sources, usually two or more generators and/or the utility, are synchronized and then connected to a common bus. When connecting the generators in parallel or synchronizing with the utility, the following criteria must be met:

- Matched/proper frequency

- Matched/correct phase rotation

- Phase voltages in phase and within specified voltage range.

Typical parameters that determine synchronization include a voltage difference of less than 5%, a frequency difference of less than 0.2 Hz, and a maximum phase angle of 5 electrical degrees between the sources.

Advantages of Parallel Power-generation Systems

Parallel operation of multiple sources provides increased reliability, flexibility in load management, and increased maintenance capabilities with minimal power outages. Multiple generators operating in parallel to a common bus can better serve emergency and critical loads.

Parallel operation of multiple generators provides greater reliability than a single generator unit. When a unit fails, the loads are redistributed among other generators in the system on a priority basis. Emergency loads that need the highest degree of reliable backup power which usually account for only a small fraction of the overall power requirement by the system.In a N+1 configuration, one generator can be offline for maintenance while the other generators are serving the required loads. Moreover, with a running spare or spinning reserve, a N+1 generator configuration will increase the reliability of the generator system to as high as 99.9%.

Parallel operation of multiple generators has higher efficiency. A large single generator may run at loads of less than 30% of capacity in low demand scenario. At this load capacity, the generator will be operating at a low efficiency which is very costly. The optimum operational point for diesel prime movers is between 75% and 80% of its rated value. At this load, the generator will be at its maximum efficiency. Fuel and maintenance costs will also be reduced. The paralleling control system can be equipped with a generator load control that can add and remove generators in response to the actual load/demand of the system.

The size of generators should match the system load requirements. It is difficult to accurately forecast future load increases and adequately plan for unanticipated additional requirements. Aggressive forecast of future loads will increase the initial investment in generators. On the other contrary, if future load forecast is inadequate, reliable standby power may be compromised or expensive post-installation system upgrades may be required. Parallel generator systems offer a better level of scalability that allows for variations in load over time and optimum operation of the installed units. If physical space planning is executed appropriately, generators can be added for additional power supply when required.

Ease of maintenance and serviceability: In an N+1 paralleled generator system, if a generator in the system fails or requires maintenance, individual units can be serviced without disrupting the function of the remaining units.

Refer to IEEE Paralleling Generator System Presentation for more details.