Insulation testing is a routine test carried out during pre-commissioning and prior to the energising of equipment and cables.

Methods used for insulation testing are:

- Insulation Resistance (IR) Testing

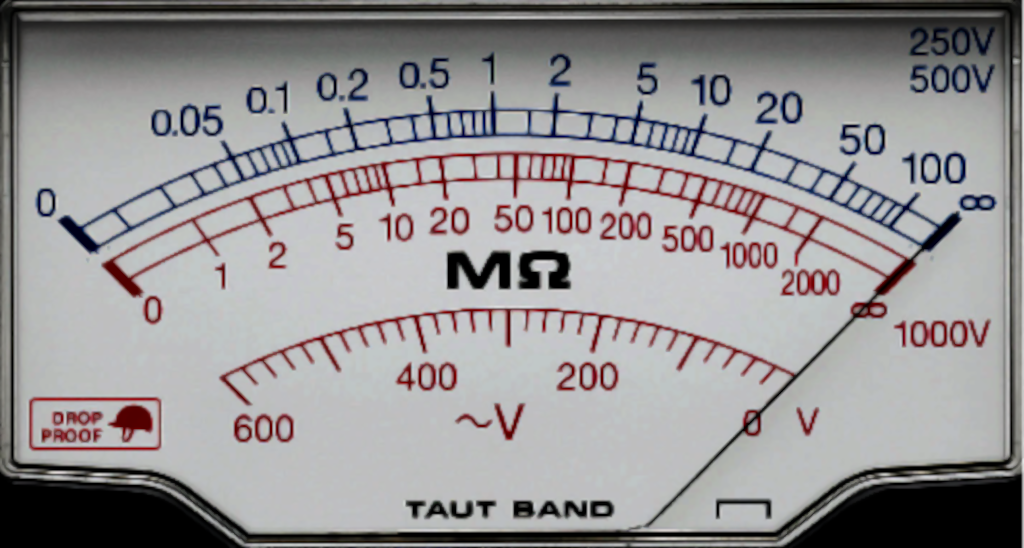

Insulation Resistance (IR) test is carried out by applying a DC voltage from an insulation tester. For correct comparative interpretation of test data, subsequent IR tests should be carried out at the same voltage level as the initial test.

Polarisation Index (PI) is the ratio between the insulation resistance measured after one minute and after 10 minutes of continuous testing at the appropriate voltage (PI = R10 min / R1 min).

After 10 minutes the capacitive current, the leakage current over the surface of the insulation and the dielectric absorption current will have stabilised.

The PI obtained gives an indication of the condition of the winding insulation with regard to its dryness and cleanliness; the PI will be lower for a dirty, wet or chemically contaminated winding insulation.

The PI, being a ratio, is practically independent of winding temperature and test voltage.

This test is commonly used for:

- motors,

- generators,

- transformers,

- LV switchgear and

- all equipment except those susceptible to damage by over-voltage (e.g. electronic components);

- High Voltage AC or DC testing

Before high voltage tests are executed, insulation resistance tests is required. High voltage testing is carried out by applying AC at power frequency or DC voltage at a level above the operating voltage.

While testing at power frequency is preferable, the a.c. test equipment must be capable of supplying the capacitive current requirement of the item under test. Thus physically large test equipment is frequently called for which is impractical for field commissioning use. For on-site commissioning, d.c. test equipment may be used.

High-voltage testing of electrical equipment, except LV cables, shall have been carried out at the Manufacturer's works.

As a warning, repeated high voltage pressure tests may introduce weak points in the insulation of windings, and such tests is not used at site to generators, motors or transformers.

This test is commonly used for:

- HV switchgear

- HV cables.

- Very Low Frequency (VLF) AC Hipots

Very Low Frequency (VLF) AC hipots produce a frequency output of 0.1 Hz and lower rather than the conventional 50 Hz or 60 Hz. VLF technology was developed for a specific reason, to more easily high voltage field test certain loads of high capacitance normally requiring very high current and power to test at the traditional power frequencies of 50 Hz or 60 Hz. Read more.

Reference: IEC 62271