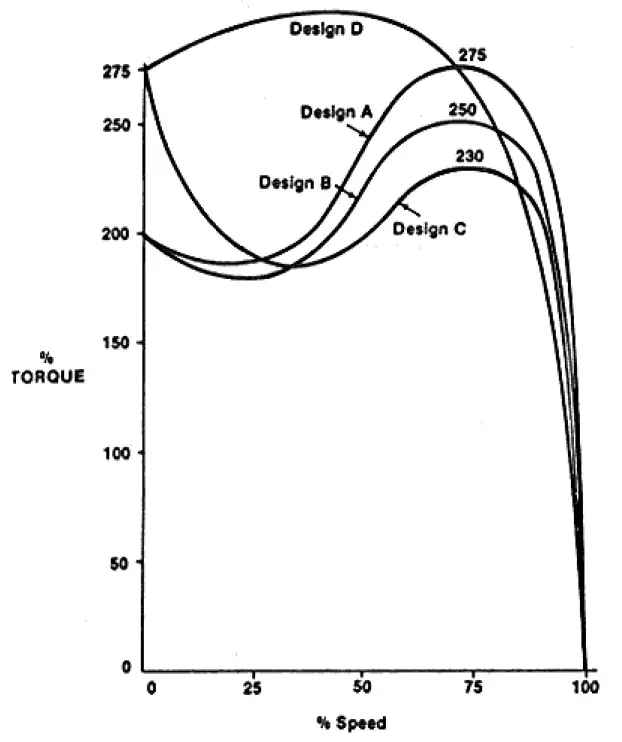

As per NEMA Standard MG-1, polyphase squirrel-cage induction motors may be one of the following. The four NEMA (National Electrical Manufacturers Association) designs have unique speed-torque-slip relationships - making them suited for different type of applications.

1. NEMA design A

1.19.1.1 Design A

A Design A motor is a squirrel-cage motor designed to withstand full-voltage starting and developing locked-rotor torque as shown in 12.38, pull-up torque as shown in 12.40, breakdown torque as shown in 12.39, with locked-rotor current higher than the values shown in 12.35.1 for 60 hertz and 12.35.2 for 50 hertz and having a slip at rated load of less than 5 percent1.

- < 5% slip

- high to medium starting current

- normal locked rotor torque

- normal breakdown torque

- suited for a broad variety of applications - like fans and pumps

2.NEMA design B

1.19.1.2 Design B

A Design B motor is a squirrel-cage motor designed to withstand full-voltage starting, developing locked- rotor, breakdown, and pull-up torques adequate for general application as specified in 12.38, 12.39, and 12.40, drawing locked-rotor current not to exceed the values shown in 12.35.1 for 60 hertz and 12.35.2 for 50 hertz, and having a slip at rated load of less than 5 percent1.

- < 5% slip

- low starting current

- high locked rotor torque

- normal breakdown torque

- suited for a broad variety of applications with normal starting torques - common in HVAC application with fans, blowers and pumps

3. NEMA design C

1.19.1.3 Design C

A Design C motor is a squirrel-cage motor designed to withstand full-voltage starting, developing locked- rotor torque for special high-torque application up to the values shown in 12.38, pull-up torque as shown in 12.40, breakdown torque up to the values shown in 12.39, with locked-rotor current not to exceed the values shown in 12.35.1 for 60 hertz and 12.35.2 for 50 hertz, having a slip at rated load of less than 5 percent.

- <5% slip

- low starting current

- very high locked rotor torque

- normal breakdown torque

- suited for equipment with high inertia and high starting torques at start - like positive displacement pumps, conveyors

4.NEMA design D

1.19.1.4 Design D

A Design D motor is a squirrel-cage motor designed to withstand full-voltage starting, developing high locked rotor torque as shown in 12.38, with locked rotor current not greater than shown in 12.35.1 for 60 hertz and 12.35.2 for 50 hertz, and having a slip at rated load of 5 percent or more.

- ≥5% slip

- low starting current

- very high locked rotor torque

- suited for equipment with very high inertia starts - like cranes, hoists etc

Different motors with the same nominal horsepower may have different start current, torque curves, speeds and other variables. When selection a particular motor for an intended task all engineering parameters must be taken into account.

| Design Letter | Slip | Starting Current | Locked Rotor Torque | Breakdown Torque | Application |

|---|---|---|---|---|---|

| Design A | < 5% | high to medium | normal | normal | Suitable for a broad variety of applications - like fans and pumps |

| Design B | < 5% | low | high | normal | Suited for a broad variety of applications with normal starting torques - common in HVAC application with fans, blowers and pumps |

| Design C | < 5% | low | high | normal | Suited for equipment with high inertia and high starting torques at start - like positive displacement pumps, conveyors |

| Design D | ≥ 5% | low | high | normal | Suited for equipment with very high inertia starts - like cranes, hoists etc |