Power cable shielding is crucial for ensuring safety,electromagnetic interference (EMI), and overall performance, especially at higher voltage levels.

Key considerations in power cable shielding

(1) Safety. Shielding helps ensure that the electric field remains contained within the cable, reducing the risk of shock or interference with other equipment.

(2) Cable Type. The need for shielding depends on the type of installation and the electrical environment (e.g., industrial, residential, or commercial).

(3) EMI Mitigation. In areas where high EMI is expected, shielding is crucial regardless of voltage level.

Shielding enhances the performance, safety, and durability of power cables. The higher the voltage, the more critical the shielding becomes for maintaining insulation integrity and minimizing electric field emissions.

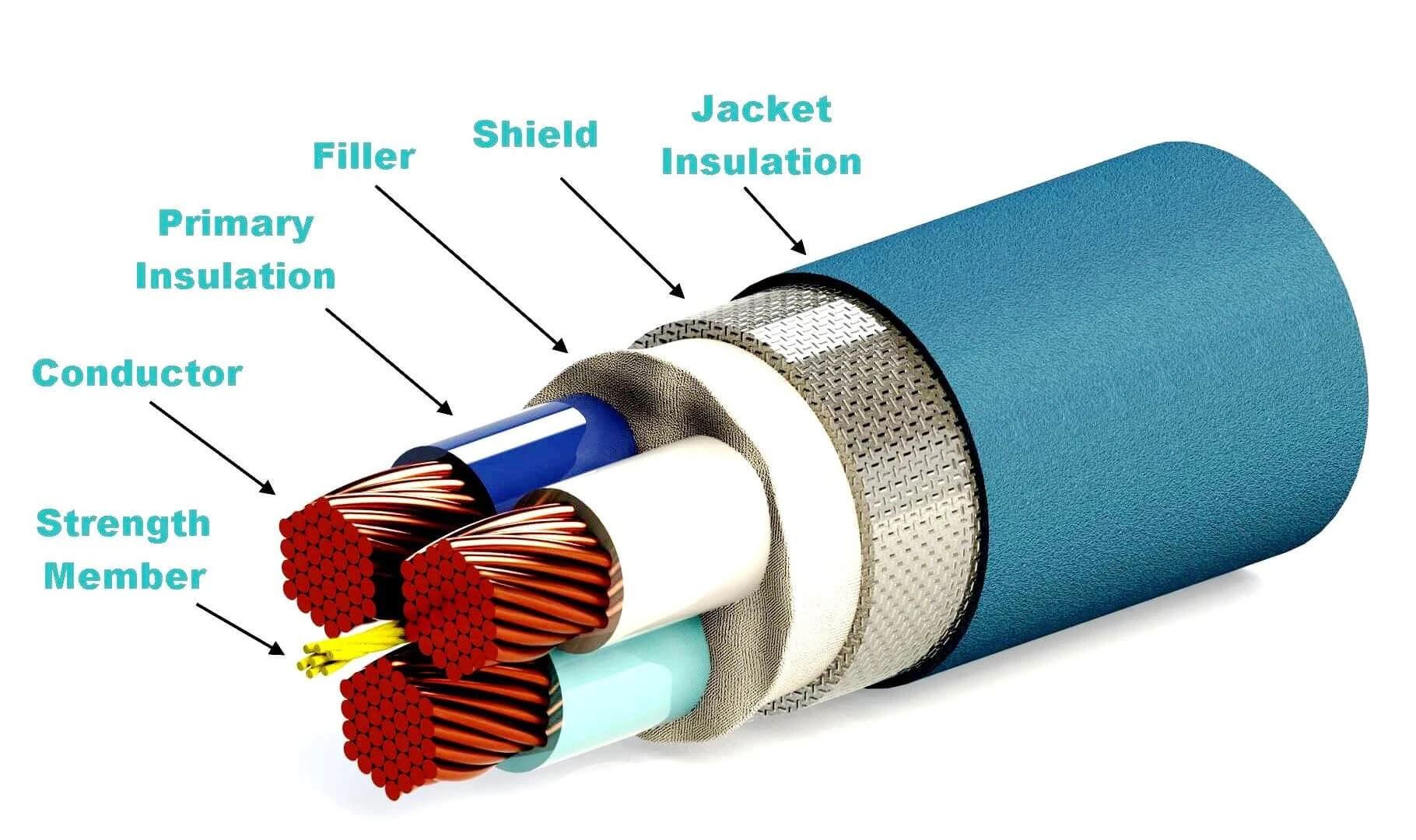

Power Cable Shielding

Shielding in power cables is used to protect the cable from external electromagnetic interference (EMI) and to prevent the cable itself from emitting EMI that could interfere with nearby equipment.

Different types of shielding

- Foil Shield

- A thin layer of aluminum or copper, often bonded to a polyester layer for strength, wrapped around the cable conductors.

- Braided Shield

- A mesh of copper or aluminum wires that provides better mechanical strength and flexibility while offering good EMI protection.

- Spiral Shield

- Copper or aluminum wire wrapped helically around the conductors, providing flexibility but somewhat less shielding effectiveness than a braided shield.

- Combination Shield

- Combines different types of shielding (e.g., foil and braid) for maximum protection.

Benefits of Shielding

- Protects against external electrical noise from motors, transformers, and other devices.

- Limits the emission of electrical noise from the cable.

- Reduces crosstalk between cables, which is especially important in data and communication cables.

Voltage Level and Shielding

The voltage level of a power cable can influence whether shielding is needed and the type of shielding that is used.

- Low Voltage Cables (LV) (up to 1,000 V)

- Shielding is typically used in LV cables to protect sensitive equipment from electromagnetic interference and to enhance safety, especially when used in environments where electrical noise is prevalent.

- Medium Voltage Cables (MV) (1 kV to 35 kV)

- Shielding is critical in MV cables to control the electric field around the conductor. Typically, these cables have a semiconducting layer and metallic shield to contain the electric field and prevent corona discharge.

- High Voltage Cables (HV) (above 35 kV)

- Shielding in HV cables is essential for ensuring safe operation. HV cables often have multiple layers of shielding, including semiconducting layers and metallic shields, to prevent electric field leakage and protect people and equipment from high voltages.

When is shielding needed?

Shielding is typically needed in environments with high EMI, sensitive equipment, or when cables are subject to high voltage, long distances, or regulatory requirements. It ensures the integrity of electrical signals, prevents interference, and enhances safety.

Key situations where shielding is necessary.

1. High Electromagnetic Interference (EMI) Environments

Industrial Settings. In areas with heavy machinery, motors, transformers, and other high-power equipment, significant EMI is generated. Shielding is required to protect the power cables from external interference and to prevent the cables from radiating EMI that could disrupt sensitive electronic equipment.

Communication and Data Centers. In places where data cables and power cables run close together, shielding prevents crosstalk and ensures the integrity of data transmission.

Hospitals and Medical Facilities. Shielding is crucial in environments with sensitive equipment, such as medical devices, which can be affected by even small amounts of electromagnetic interference.

2. When Handling Sensitive Equipment

Instrumentation and Control Systems. Shielding is necessary to protect signals from interference that could lead to errors in instrumentation and control systems.

Audio/Video Equipment. High EMI levels can cause distortion or noise in audio and video signals, so shielding is needed for power cables in these applications.

3. High Voltage and Medium Voltage Cables

Medium and High Voltage Cables. Shielding is required to control the electric field surrounding the conductors. This prevents the risk of electric field leakage and corona discharge, which can lead to insulation failure or damage to nearby equipment.

Substation and Transmission Lines. In power distribution and transmission systems, shielding is necessary to protect people and equipment from the high electric fields generated by medium and high voltage cables.

4. Proximity to Other Cables or Electrical Equipment

Parallel Runs of Power and Signal Cables. When power cables run in parallel with communication or control cables, shielding is necessary to prevent EMI from affecting the signals in adjacent cables.

Mixed-use Installations. In installations where different types of cables (e.g., high-power and low-power, or signal and control) are used in the same space, shielding is needed to reduce the risk of interference between them.

5. Compliance with Standards and Regulations

Regulatory Requirements. Some standards and regulations (e.g., IEEE, IEC) may require shielding in certain environments or for specific cable types to meet safety and performance criteria.

Electromagnetic Compatibility (EMC). Shielding is essential to ensure compliance with EMC standards, which regulate the levels of EMI that electronic and electrical devices can emit and must resist.

6. Long Cable Runs

Long-distance Cable Runs. Over long distances, cables are more susceptible to picking up noise and interference. Shielding helps maintain signal integrity by protecting against environmental noise along the length of the cable.

7. Underground and Subsea Cables

Buried or Subsea Installations. Shielding in underground or subsea cables protects the cable from external electrical fields, moisture, and other environmental factors that could compromise the cable's performance.

8. Hazardous Locations

Explosive or Flammable Environments. In areas with flammable materials, shielding is used to contain electrical sparks or discharges that could ignite surrounding materials.

How do shields work?

Shields in power cables work by blocking, reflecting, or absorbing electromagnetic interference (EMI) and containing electric fields generated by the conductors. The primary purpose of shielding is to prevent external interference from affecting the signal or power in the cable and to stop the cable itself from emitting interference that could affect nearby equipment.

1. Electromagnetic Interference (EMI) Protection.

Blocking and Reflecting EMI. The shield acts as a barrier around the cable’s conductors. When external electromagnetic fields (like those from motors, transformers, or other electrical equipment) try to pass through the shield, they are either blocked or reflected back by the conductive material of the shield (usually copper, aluminum, or a conductive foil). This prevents the interference from reaching the cable’s internal conductors, thus protecting the signals or power being transmitted.

Absorbing EMI - In some cases, the shield can also absorb a portion of the EMI. The absorbed energy is then dissipated as heat. This reduces the strength of the electromagnetic fields that might otherwise interfere with the cable’s performance.

2. Reducing Radiated EMI

Containing the Electric Field - Electrical conductors carrying current generate their own electric and magnetic fields. In unshielded cables, these fields can radiate outward and interfere with nearby devices or cables. The shield helps contain these fields within the cable by providing a path for the electric field lines. This limits the emission of electromagnetic noise into the surrounding environment, minimizing interference with adjacent systems (e.g., data communication lines or sensitive electronics).

Grounding the Shield - A key part of shielding is grounding. The shield is typically connected to ground at one or both ends of the cable. This provides a low-impedance path for the absorbed or blocked interference to dissipate safely into the ground. Grounding prevents the shield itself from becoming a source of interference or accumulating electrical charge.

3. Types of Shielding and Their Functions

Different types of shielding provide different levels of protection, depending on the application and the kind of interference present.

Foil Shields - These are thin layers of conductive material (usually aluminum or copper) wrapped around the cable’s conductors. Foil shields are particularly effective at blocking high-frequency interference, such as radio frequency (RF) and microwave signals, by creating a continuous, conductive barrier.

Braided Shields - These consist of woven strands of copper or aluminum and offer flexibility along with good low-frequency shielding. They are effective at protecting against power frequency (50/60 Hz) interference, such as from transformers and power lines.

Combination Shields - Some cables use both a foil and a braided shield to provide protection against both high-frequency and low-frequency interference. This combination maximizes shielding performance by addressing different types of interference.

4. Capacitance and Shielding

Capacitive Coupling - When cables run close to one another, there is a risk of capacitive coupling, where an electrical field from one cable induces a voltage in another. Shielding reduces capacitive coupling by containing the electric field within the shield, preventing it from influencing adjacent cables.

5. Controlling the Electric Field in High-Voltage Cables

Semiconducting Layer - In high-voltage (HV) and medium-voltage (MV) cables, a shield is often combined with a semiconducting layer that surrounds the conductor. This layer evenly distributes the electric field within the insulation, preventing points of high stress that could lead to dielectric breakdown or insulation failure.

Metallic Shield - A metallic shield is used in HV and MV cables to carry fault current to ground in case of an insulation failure. It also limits the electric field around the cable, ensuring that it doesn’t radiate into the surrounding environment.

6. Magnetic Shielding

Magnetic Field Protection - In some cases, shielding may also protect against magnetic fields, although this is less common for standard power cables. Specialized materials, like mu-metal, may be used to shield against low-frequency magnetic fields by redirecting the magnetic flux lines through the shielding material.

Summary of Shielding Mechanisms

- Blocking/Reflecting EMI. Conductive materials reflect or block external electromagnetic fields from entering the cable.

- Absorbing EMI. The shield can absorb some interference and dissipate it as heat.

- Containing Electric Fields. Shields prevent electric fields from radiating out and causing interference with nearby systems.

- Grounding. The shield is connected to ground to safely direct interference away from the cable.