Electrical Engineers may sometimes face some issues on how to implement proper earthing (grounding) on a project. This is a predicament I encountered on a water pipeline project in Sunshine Coast, Queensland, Australia. The balance tank is located on top of the mountain with top soil covering of only less than half a meter, deeper than that will be granite. Normal earth rods will not work. The only solution is to provide a concrete encased ring of bare copper surrounding the balanced tank.

Steel in concrete work is generally protected against corrosion by the concrete and can act satisfactorily as an electrode, if provision is made to ensure electrical continuity and adequate conductivity. Steel in concrete has an electro-potential similar to that of copper and may therefore be bonded to copper or copper-covered earth electrodes. Note, however, that galvanized steel is strongly electronegative to both copper and steel in concrete so that an earth electrode of bare galvanized steel should not be bonded to either of them.

Concrete is hygroscopic with low resistivity as it attracts moisture and thus behaves as a semiconducting medium as per BS 7430. A concrete has a typical resistivity of 30-90 Ω-m. This particular medium can be used in highly resistive soils where a metallic electrode is encased in concrete which lower the electrode resistance than a similar electrode buried directly in ground earth because this encasement lessens the resistivity of the material surrounding the metal element.

However, there are two disadvantages of this method.

- Corrosion of the rebar material can be caused in case where a small DC current is present.

- Concrete may be broken due to pressure produced by corroded steel or when large quantity of current passes through the concrete which can vaporize its moisture.

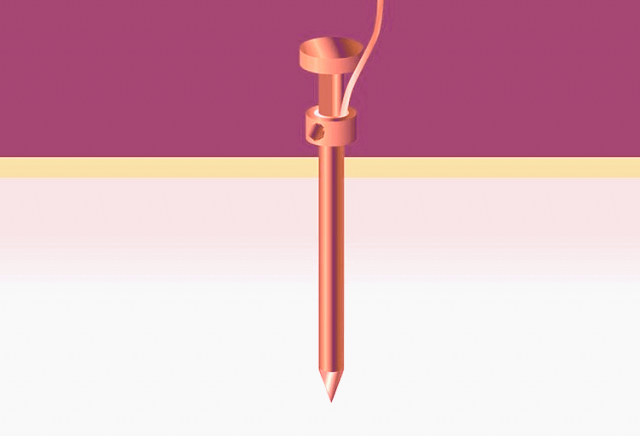

Concrete-encased metal rod constituted a major breakthrough in earthing systems technology due to its effective performance and now it is one of the best alternatives to pipe and driven rod electrodes buried in the soil. Electrodes that are encased in concrete are proven to be capable of withstanding very large amount of earth current, and the rate of corrosion of such electrodes is lower than that of electrodes driven directly in ground earth. The resistance of a backfilled electrode encased in low resistivity material such as a conducting concrete can be calculated from the following equation as proposed by BS-7430.

The addition of bentonite into the concrete mixture can further improve the concrete material property by lowering its resistivity. It was found that for a specific dimension, the earthing resistance is only a factor of 0.3 of the localized soil resistivity.