Cable Selection Parameters

The normal practice for determining the size of cables is using a continuous current operation. In this case, the cable sizing will be straightforward.

What if the load is intermittent? What will be the equivalent continuous current to be used in the cable sizing calculations? If the maximum current will be used, the cost will be very high, on the contrary, the minimum current may provide an under-sized cable.

Proper cable selection requires some parameters required on the calculation such as

- Load current

- Ambient temperature

- Allowable Cable operating temperature

- Short-circuit current withstand

Equivalent Continuous Current

There are some types of loads where the load is switched on and off before the cable has time to cool completely. Depending upon the load cycle, it may be possible to select a smaller cable for intermittent operation than would be the case if the load was continuously applied. When a current in excess of the normal rated current is applied, the heating of the cable will be quicker operation than the cooling.

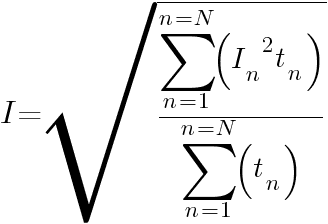

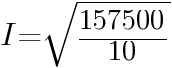

The formula for calculating the equivalent continuous current from an intermittent operation is:

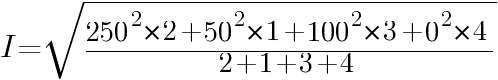

Example:

Suppose a process load cycle is as follows:

- 250 A for 2 min

- 50 A for 1 min

- 100 A for 3 min

- 0 A for 4 min

then applying the expression for continuous current

Therefore a continuous current of 125.5A flowing over the 10 minutes cycle time would produce the same heating effect as the individual cyclic currents, and the size of the cable could be selected based on 125.5 A.

References:

Practical Power Distribution for Industry by Jan de Kock