An arc fault is a high-power discharge of electricity between two or more conductors. This discharge can manifest in a number of ways.

- Series Arc Fault

Occurs in a single wire when there's a break, like when a conductor is compromised but still touching, allowing current to flow. This fault can be due to damage or wear and tear. An example is a damaged cord on a lamp might produce a series arc fault. - Parallel Arc Fault

This fault is a discharge that jumps from one wire to another. Parallel Arc Fault might occur if two wires have compromised insulation and touch each other.

Arc faults can generate significant heat, which can ignite nearby combustible materials, leading to an electrical fire. These types of faults are especially dangerous because they can occur even when devices or circuits seem to be functioning normally.

Causes of Arc Faults

Arc fault can be caused by several factors. The list below are not comprehensive but usually the common causes of arc fault.

- Deteriorated, Damaged or Aged Wiring

Over time, the insulation around wires can become worn or cracked, leading to exposed conductors. - Punctured Insulation

A nail or screw inadvertently penetrating an electrical cable behind a wall, it can expose the conductors inside. - Loose or Improper Connections

Over time, connections can loosen, or they might not have been properly made to begin with. - Overheated Wires or Equipment

Overheating can result from overloading circuits or using equipment that draws more current than the wiring can safely handle. - Worn Out Electrical Devices

As electrical devices age or get damaged, their internal parts might not make proper connections, leading to arc faults. - Physical Stress

External stress on cords, like bending, can lead to internal wire damage. - Faulty Appliances and Equipment

Malfunctioning appliances or equipment with damaged wiring can lead to arc faults. - Rodent or Pest Activity

Rodents and pests can chew through electrical wiring, causing exposed conductors and potential arc faults. - Damaged Cables or Cords

Frayed or damaged power cords, extension cords, or cables can result in exposed conductors and arcing. - Environmental Factors

Dust, dirt, or other contaminants on electrical components can cause arcing by bridging the gap between conductors.

Detection and Prevention

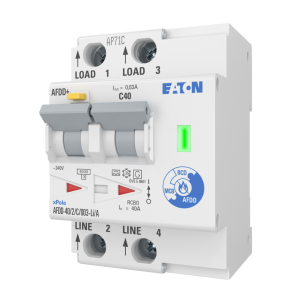

The danger posed by arc faults has led to the development of Arc-Fault Circuit Interrupters (AFCIs). AFCIs is particularly used in the National Electrical Code (NEC). AFCIs are special types of electrical receptacles or circuit breakers designed to detect and respond to potentially dangerous electrical arcs. They differ from Ground Fault Circuit Interrupters (GFCIs) in that while GFCIs are designed to protect people from electrical shocks, AFCIs are designed to prevent fires caused by arc faults.

If an AFCI detects an abnormal arcing condition, it will trip the circuit, interrupting the electrical flow and potentially preventing a fire.

IEC has likewise addressed arc-faults and their detection through various standards. One of the most notable standards related to arc-fault detection is IEC 62606 - General requirements for arc fault detection devices (AFDDs).

International Standards

The National Electrical Code (NEC) has provisions that require the use of AFCIs in various parts of residential homes to prevent fires due to arc faults. These requirements have expanded over different editions of the NEC, reflecting a growing awareness of the importance of arc fault protection.

The IEC 62606 - General requirements for arc fault detection devices standard provides:

- Definition and Classification

Outlines what constitutes an Arc Fault Detection Device (AFDD) and offers classifications for these devices. - Requirements

Lists the requirements for AFDDs in AC electrical installations, either for household or similar uses with rated voltages not exceeding 440 V AC and rated currents not exceeding 63 A. - Testing Methods

Specifies the methods for testing AFDDs to ensure they can reliably detect and respond to arc faults. - Product Markings and Documentation

Provides guidance on the markings that should be present on the AFDD and any accompanying documentation.

Arc Fault Detection Device - Operational Characteristics

Details the operational characteristics that an AFDD should possess. This includes the device's ability to detect series and parallel arc faults and its response times. - Safety Aspects

List safety requirements for the AFDDs to ensure they do not introduce any additional risks when installed in an electrical circuit.

Recommendations

Arc faults are dangerous electrical phenomena that can potentially lead to fires. Proper precautions, including the use of AFCIs or AFDDs and adherence to electrical codes and standards, can significantly reduce the associated risks.

The use of AFCIs and AFDDs has become more widespread in recent years due to the increased awareness of the risks associated with arc faults. The primary goal of these devices is to detect potentially hazardous arc-faults and interrupt the circuit to prevent fire hazards.