This is Part 3 of the series of articles about three (3) phase Ac motor protection. Part 1 could be found here and the link for Part 2 is here.

Locked-Rotor Protection

Locked-rotor current and starting current of an induction motor seem to be the same, but they are not. The terms have different meanings and significance. Locked rotor current is the current drawn by the motor at its rated voltage when its rotor is not rotating. If the motor is started using Direct Online (DOL) method, and the rated voltage is applied at its terminal, the starting current will be equal to the locked rotor current. But if the starting method is reduced voltage type, the starting current will be less than the locked rotor current

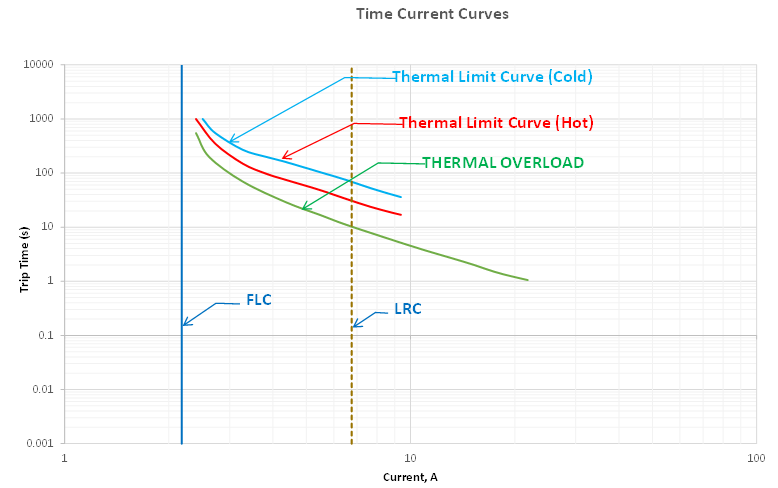

Overload relays provide protection for motor running conditions. If the motor fails to start caused maybe by mechanical fault conditions of the load or a single-phase line, will the motor running protection provide for locked-rotor protection? To determine if locked rotor protection is provided, it is necessary to know the length of time the motor will safely endure locked rotor current. This information will be used to determine the relay tripping time coordinating the motor thermal damage curve with the relay current and tripping time. The relay current and tripping time must be below the motor thermal damage curve to provide locked rotor protection.

Under single-phase locked rotor conditions, the actual line current will be approximately 86.5% of the current under three(3) phase locked rotor conditions. The lower current locked rotor current will increase the relay tripping time. In this case, the current in the windings will be full current in one winding and half normal current in each of the other two windings.