Are you aware of this provision in the Philippine Electrical Code? If yes, have you been complying with this provision in your electrical design or installation?

In my humble opinion, this provision of the Philippine Electrical Code is an oblivious provision in the Code to most electrical practitioners. Probably the compliance to this provision is only incidental. This is disturbing but this is reality.

Temperature Limitations

Section 1.10.1.15(C) Temperature Limitations of the PEC states

The temperature rating associated with the ampacity of a conductor shall be selected and coordinated so as not to exceed the lowest temperature rating of any connected termination, conductor, or device. Conductors with temperature ratings higher than specified for terminations shall be permitted to be used for ampacity adjustment, correction, or both.

What does this provision mean?

Electrical cables and/or conductors have current-carrying capacities which are dependent on the type of their insulation. The table below lists some typical conductor insulations as per PEC

| Insulation | Type Letter | Maximum Operating Temperature | Application |

|---|---|---|---|

| Flame-retardant, heat-resistant thermoplastic | THHN | 90°C | Dry and damp location |

| Flame-retardant, moisture- and heat-resistant thermoplastic | THWN | 75°C | Dry, damp and wet locations |

| Flame-retardant, moisture- and heat-resistant thermoplastic | THW | 75°C | Dry, damp and wet locations |

| Flame-retardant, moisture resistant thermoplastic | TW | 60°C | Dry, damp and wet locations |

The Philippine Electrical Code has conductors that have dual ratings.

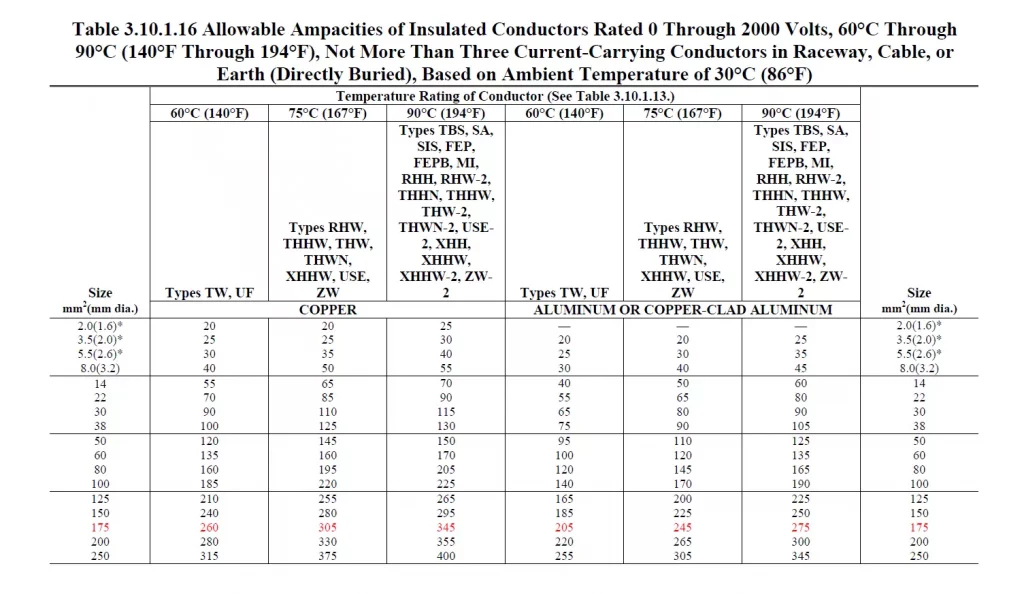

From the above table, some cable types appear in both 75°C and 90°C columns. For example, a 2.0 mm² THW has an ampacity of 20A at 75°C while it is rated 25A at 90°C. This dual rating is explained better in the image below.

Cables with insulation type THHN/THWN are both rated at 90°C and 75°C respectively depending on the application.

Industry Practice

Manufacturers commonly use 90°C-rated lugs on equipment rated only 60°C or 75°C. The use of the 90°C-rated lug in this type of equipment does not allow the installer to use 90°C wires at the 90°C ampacity.

The wire temperature rating allowed for use in circuit breaker lugs is 75°C. While it is acceptable to use 90°C wire, that 90°C wire must be sized as if it is 75°C wire. This is according to the UL standard for circuit breakers, which is summarized as follows:

(1) Breakers rated 125 A or less must be marked for use with 60°C, 60/75°C, or 75°C only wire.

(2) For breakers rated more than 125 A, the proper wire temperature rating is 75°C and the marking is optional.

(3) Wire with a higher temperature rating can be used (e.g. 90°C), but the ampacity of the wire must be based on the wire temperature marked on the breaker.

Therefore, as marked on the breaker, the wire must be sized as 75°C wire. Even when using 90°C wire, the wire must be sized as if it is 75°C wire.

Please note that when a "-2" is added to the end of an insulation type (such as THWN-2) the conductor can be used in a wet or dry location at its 90°C a mpacity rating.