Insulation Level General Categories

Selection of the appropriate insulation level for power cables depends on the phase-to-phase voltage and two general categories shown below:

- 100% Voltage Level.

- Cables in this category may be applied where the power system's protective relaying apparatus can clear a ground fault (an unintentional connection to ground of one or more current-carrying conductors) in less than 1 minute. These cables are generally used in grounded systems.

- 133% Voltage Level.

- This insulation corresponds to that formerly designated for ungrounded systems. Cables in this category may be ap plied in those situations where the clearing time requirements of the 100% category cannot be met and yet there is adequate assurance that the faulted section of cable can be cleared in less than an hour. Of the two, it is recommended that the 133% voltage level be used for power circuits as it ensures maximum protection of both the conductors and the surrounding environment should a fault occur on a cable.

Insulation Level Selection Guide

Selecting the appropriate insulation level for electrical power cables is critical for ensuring safety, reliability, and performance in power distribution systems. The insulation must be chosen based on several factors, including the system voltage, operating conditions, and environmental considerations.

Here’s a guide to the process:

1. System Voltage

- Rated Voltage

- The insulation level of a cable must match or exceed the system's rated voltage. This ensures that the insulation can withstand the electrical stress during normal operations.

- Voltage Classification

- Low voltage (LV) systems: up to 1 kV

- Medium voltage (MV) systems: 1 kV to 33 kV

- High voltage (HV) systems: 33 kV to 230 kV

- Extra high voltage (EHV) systems: above 230 kV

The insulation material and thickness are designed to handle these voltages safely.

2. Current Capacity and Thermal Considerations

3. Insulation Material Properties

Common Insulation Materials

- Polyvinyl Chloride (PVC)

- Used in LV cables, flexible but limited to lower temperatures.

- Cross-Linked Polyethylene (XLPE)

- Widely used in MV and HV cables due to its high temperature tolerance and dielectric strength.

- Rubber

- Flexible, used in harsh or mobile environments.

- Ethylene Propylene Rubber (EPR)

- High thermal resistance, used for MV applications.

The choice depends on the operating voltage, mechanical flexibility, fire resistance, and environmental conditions.

4. System Grounding

The insulation level also depends on whether the system is grounded or ungrounded.

Ungrounded systems may require higher insulation levels because the cable must withstand overvoltages from faults.

Solidly grounded systems usually have lower insulation requirements because fault voltages are limited.

5. Environmental Considerations

- Moisture and Water Exposure

- For installations in wet areas or underground, water-resistant or moisture-blocking insulation is required (e.g., XLPE or EPR).

- Chemical Exposure

- Insulation must resist chemicals and oils in industrial environments (e.g., PVC for chemical resistance).

- UV Exposure

- Cables exposed to direct sunlight need UV-resistant insulation (e.g., XLPE or certain types of PVC).

- Mechanical Stress

- Cables subjected to physical stress need tougher insulation materials with good abrasion resistance.

6. Standards and Regulations

National and international standards (such as IEC, NEC, and IEEE) provide guidelines on insulation levels for various voltage classes and environmental conditions.

Compliance with these standards ensures that the cable performs reliably under operating conditions.

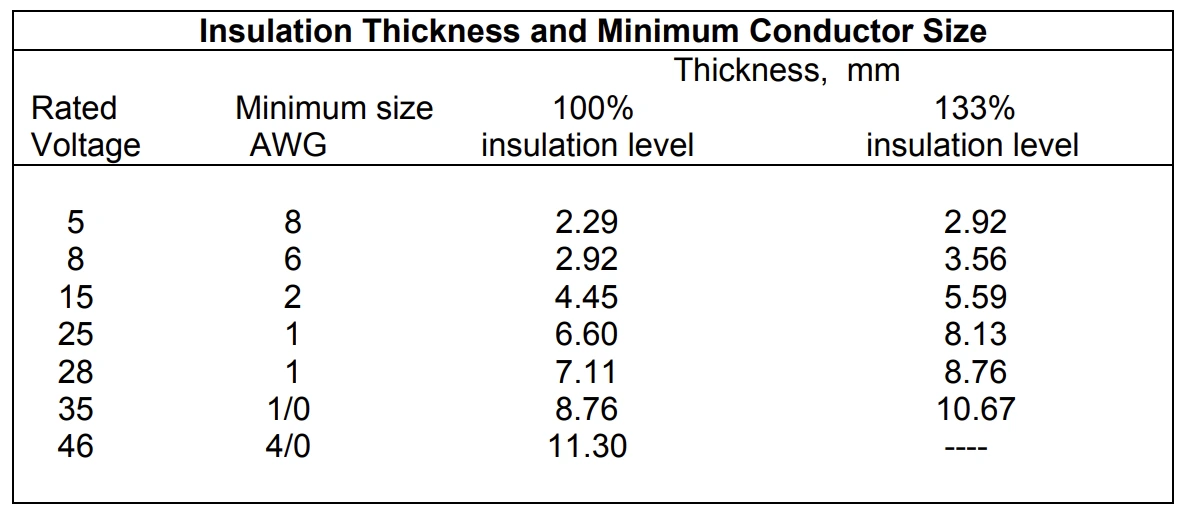

7. Insulation Thickness

The thickness of the insulation is directly related to the voltage level and the type of system. Higher voltages require thicker insulation to prevent breakdown.

Refer to manufacturer guidelines or standards (e.g., IEC 60502, NEC) for appropriate thickness specifications for different voltage levels.

8. Fire Safety and Flame Retardancy

In certain applications (e.g., buildings, tunnels), fire-retardant or low-smoke insulation materials may be required to meet fire safety codes (e.g., LSZH—Low Smoke Zero Halogen).

When to Choose 100% vs 133% Voltage Level

The terms 100% insulation level and 133% insulation level refer to the design of cable insulation for different system grounding configurations and operating conditions, especially in medium voltage (MV) systems. These percentages relate to the insulation's ability to withstand system voltage during normal and fault conditions. The choice between these insulation levels depends on the system's grounding method and how long the cable will be subjected to overvoltages during faults.

1. 100% Insulation Level

Application. Designed for solidly grounded systems.

Cables with 100% insulation level are intended for systems where the voltage does not exceed the cable's rated voltage during normal conditions or faults.

Grounding Method. Typically used in solidly grounded systems, where the fault voltage is limited by the grounding system. When a fault occurs (e.g., a line-to-ground fault), the grounding system restricts the overvoltage to a low level, meaning the cable will not be subjected to excessive voltages for extended periods.

Fault Duration. Ground faults are expected to be cleared quickly (within seconds or minutes).

Example:

A 15 kV rated cable with 100% insulation level is intended for a system with a maximum phase-to-ground voltage of about 8.66 kV.

2. 133% Insulation Level

Application. Designed for ungrounded or impedance-grounded systems.

The cable with 133% insulation level has thicker insulation to handle potential overvoltages during faults.

Grounding Method. Used in ungrounded, high-resistance grounded, or impedance-grounded systems, where a single line-to-ground fault does not immediately cause a system shutdown. In these systems, the voltage on the unfaulted phases can rise to 1.73 times the normal voltage.

Fault Duration. The system can continue operating for a longer time with a ground fault (sometimes indefinitely, depending on system design). The higher insulation level accounts for the prolonged exposure to elevated voltages.

Example:

A 15 kV rated cable with 133% insulation level is designed to handle phase-to-ground voltages that may rise up to 11.55 kV (133% of 8.66 kV) under fault conditions.

3. System Grounding and Fault Handling

Solidly Grounded Systems (100% Insulation). These systems are designed to quickly clear ground faults, and the voltage on unfaulted phases remains close to normal during the fault. Therefore, 100% insulation level is sufficient.

Ungrounded or Impedance-Grounded Systems (133% Insulation). In these systems, a ground fault may not be cleared immediately. During a fault, the voltage on the healthy phases increases, requiring thicker insulation to withstand these voltages over time.

4. Practical Example

A 15 kV cable rated for 100% insulation is designed for a solidly grounded system, with an insulation level to handle the nominal system voltage of 8.66 kV (phase-to-ground voltage).

A 15 kV cable rated for 133% insulation is designed for an ungrounded or impedance-grounded system, where the phase-to-ground voltage during a ground fault can rise to 11.55 kV, requiring thicker insulation to handle this increase.

5. When to Choose 100% vs. 133% Insulation

100% Insulation Level. Choose this for systems that are solidly grounded and have quick fault-clearing mechanisms, where overvoltages are minimal and brief.

133% Insulation Level. Choose this for systems that are ungrounded or impedance-grounded, where ground faults may persist and the voltage on unfaulted phases can rise for extended periods.

Conclusion

100% insulation level is for systems with solid grounding and short fault duration.

133% insulation level is for systems with ungrounded or impedance-grounded configurations, where faults may persist and require additional insulation strength to handle prolonged elevated voltages.