What is Arc-Flash?

Arc-Flash is a type of electrical explosion that occurs when an electrical current leaves its intended path and travels through the air from one conductor to another or to the ground.

Arch-flash can result in very high temperatures, a pressure wave, and a bright flash of light. The energy released during an arc-flash incident can cause severe injuries, equipment damage, and even fatalities.

Arc-Flash Hazards

Arc-flash hazards are:

- Thermal burns

- Temperatures can reach as high as 35,000 degrees Fahrenheit (around 19,400 degrees Celsius), which can cause severe burns.

Electrical Burn on Hand and Arm Electrical Burn on Arm Fresh Electrical Burns - Blast pressure

- The sudden release of energy can create a pressure wave that can throw workers off their feet and cause physical injuries.

Exploded Main Bus Cover Arc Flash Mark Damaged Main Bus Joint Cover Burnt Divider at Load Side Cable Termination 13.8kV Switchgear Busbar Burnt 13.8kV Switchgear Busbar Joint Melted 13.8kV Switchgear Busbar Joint Melted 13.8kV Switchgear Busbar Joint Melted 13.8kV Switchgear Busbar Joint Melted - Flying shrapnel

- The explosion can cause metal parts to melt and fly through the air, potentially injuring workers. - Blindness

- The intense light from the arc can damage the eyes, leading to temporary or permanent blindness. - Hearing loss

- The explosion can be very loud, damaging the ears. - Inhalation injuries

- The explosion can produce toxic smoke and gases. - Electrocution

- Direct contact with live electrical components can result in fatal electrical shock.

Arc-Flash Mitigations

The list of mitigations provided below are not comprehensive. The Electrical Engineer or Safety Officer need to determine the mitigations applicable to a particular scenario or situation. A comprehensive approach to arc-flash hazard mitigation includes a combination of engineering controls, administrative controls, training, and personal protective equipment. Regular updates and reviews of safety protocols and equipment are essential, given the severe consequences of an arc-flash incident.

- Risk Assessment

- Regularly perform arc-flash hazard analyses to determine the potential for an arc-flash and its potential energy. - Equipment Maintenance

- Proper maintenance reduces the risk of equipment malfunctioning which can lead to arc-flashes. - Arc-Flash Boundaries

- Determine safe working distances from live electrical parts. The closer a worker is to the hazard, the greater the risk. - Personal Protective Equipment (PPE)

- Workers must wear appropriate PPE such as flame-resistant clothing, face shields, gloves, and other gear.

- Labeling

- Clearly label electrical equipment with warning labels indicating the arc-flash boundary and necessary PPE. - Training

- Ensure that all electrical workers are trained in arc-flash safety, understand the hazards, and know how to protect themselves. - Use of insulated tools and equipment

- Using insulated tools reduces the risk of accidental contact. - Remote operations

- Whenever possible, operate equipment remotely to keep workers away from the potential arc-flash hazard. - De-energizing equipment

- Always de-energize equipment before working on it when feasible. - Arc-Flash Relays -

- These devices can detect the light from an arc-flash and quickly trip the circuit, reducing the energy of the arc. - Current-limiting fuses

- These can reduce the magnitude of an arc-flash by quickly clearing the fault.

Arc-Flash Standards

Arc flash hazards are governed by various standards, depending on the region and the nature of the operations. In the UNited States, some of the primary standards are:

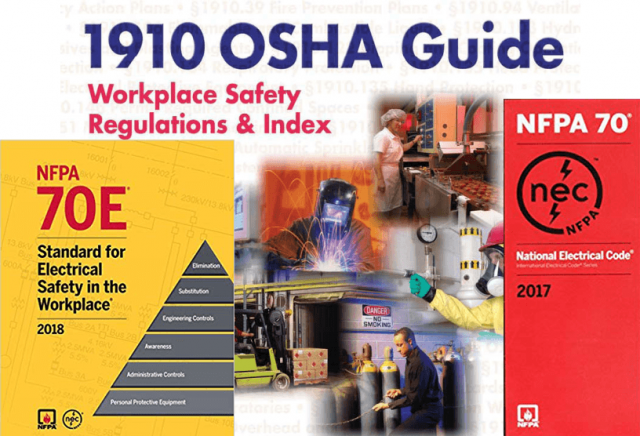

- NFPA 70E - Standard for Electrical Safety in the Workplace

- This is a key standard developed by the National Fire Protection Association. It provides guidance on electrical safety-related work practices. NFPA 70E emphasizes the importance of a risk assessment approach and addresses arc flash in detail, specifying requirements for Personal Protective Equipment (PPE), boundaries, and labeling. - IEEE 1584 - Guide for Performing Arc-Flash Hazard Calculations

- Produced by the Institute of Electrical and Electronics Engineers, this guide provides methods for calculating the incident energy and arc flash boundary. - OSHA (Occupational Safety and Health Administration) Regulations

- OSHA's 29 CFR 1910 Subpart S and 29 CFR 1926 Subpart K provide regulations related to electrical safety. While OSHA doesn’t specifically define arc flash hazard analysis requirements, it does reference the NFPA 70E and other consensus standards in its regulations. - NEC (National Electrical Code) - NFPA 70

- The NEC, while primarily an installation code, has some requirements related to worker safety and arc flash. For instance, it mandates labeling to warn of potential arc flash hazards.

For other countries or regions, there might be local standards or adaptations of international ones. For example, in Canada, CSA Z462 "Workplace Electrical Safety" is the analogous standard to NFPA 70E. When looking to address arc flash hazards, it's essential to consider all relevant standards, industry best practices, and ensure compliance with local, regional, and national requirements.

Arc-Flash IEC Standards

While IEC standards provide a global perspective, local and regional regulations or adaptations might exist. Always ensure that you are compliant with the requirements specific to your region or country.

- IEC 61482-1-1 "Live working - Protective clothing against the thermal hazards of an electric arc - Part 1-1: Test methods - Method 1: Determination of the arc rating (ELIM, ATPV and/or EBT) of clothing materials and of protective clothing using an open arc."

- This standard encompasses Test methods to determine the arc rating of protective clothing materials and clothing products. Specifies procedures to test the heat transmission on exposure to an electric arc. Helps in the determination of arc thermal performance value (ATPV) or energy of breakopen threshold (EBT). - IEC 61482-2: "Live working - Protective clothing against the thermal hazards of an electric arc - Part 2: Requirements."

- This standard specifies requirements for protective clothing used in work, where there are electric arcs, defines two classes of garment protection based on the total arc energy levels they can protect against.