Introduction

Materials for protection against lightning shall be properly selected by the Electrical Engineer. The Philippine Electrical Code 2017 edition categorizes materials for protection against lightning as Class I and Class II. What is the difference between the two (2) material classes? What are the applications of each material class?

Definition of Terms

- Class I Materials

- Lightning conductors, air terminals, grounding electrodes, and associated fittings required for the protection of structures not exceeding 23 m (75 ft) in height.

- Class II Materials

- Lightning conductors, air terminals, grounding electrodes, and associated fittings required for the protection of structures exceeding 23 m (75 ft) in height.

Protection against Lightning - Philippine Electrical Code 2017

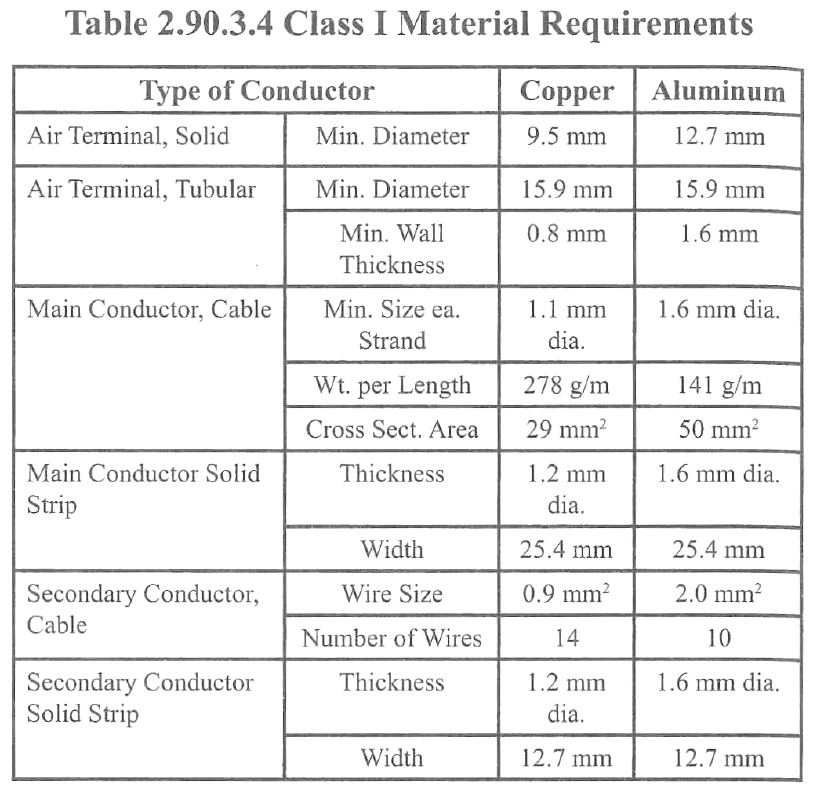

2.90.3.4 Materials, Class I. Table 2.90.3.4 gives minimum sizes and weights for air terminals, and main and secondary conductors for Class I structures. Secondary conductors used for bonding and interconnecting metallic bodies to the main conductor, and which will not be required to carry the main lightning current, may be reduced in size but shall not be less than 14 mm2 copper or equivalent. Conductors for interconnection to metal water systems, steam or hot water heating systems, or other metallic masses having a low resistance to ground shall be main conductor size.

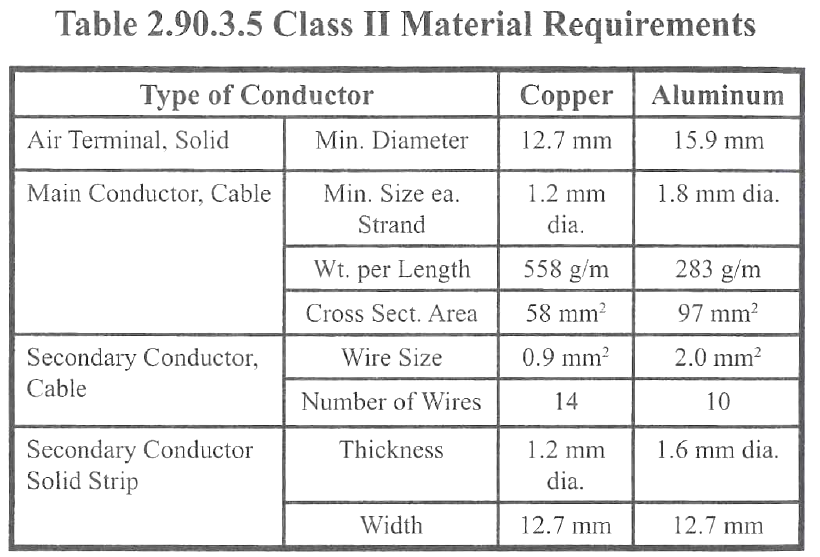

2.90.3.5 Materials, Class II. Table 2.90.3.5 gives minimum sizes for air terminals, and main and secondary conductors for Class II structures. Systems on these structures shall be installed in accordance with requirements of Class I and, in addition, shal'l comply with the following requirements: If part of a structure is over 23 m in height (as a steeple) and the balance of the structure is under 23 m in height, the following requirements for air terminals and conductors shall apply only to the sections over 23 m in height. Class II conductors installed on parts of a structure exceeding 23 m in height shall be coursed to ground and also interconnected with the rest of the system. Only metal splicers and connectors welded or secured with bolts are acceptable for use on Class II structures.

Use of Aluminum

The Philippine Electrical Code 2017 allows copper and aluminum for lightning protection. The use of aluminum however have some restrictions as stated in Article 2.90.3.8 Use of Aluminum

2.90.3.8 Use of Aluminum. Aluminum systems shall be installed in accordance with other applicable sections and with the following:

(A) Aluminum lightning protection equipment shall not be installed on copper roofing materials or other copper surfaces.

(B) Aluminum materials shall not be used for direct grounding of lightning protection systems. Fittings connecting aluminum down conductors to copper or copper-clad grounding equipment shall be of the bimetallic type.

(C) Connectors shall be suitable for the material of the conductor. Conductors of dissimilar metals shall not be intermixed in a connector unless the connector is suitable for the purpose and conditions of use. Bimetallic connections shall be installed at a point not less than 300 mm above grade level. Where downleads are concealed, the connection shall be at least 300 mm above the lowest slab.

(D) An aluminum conductor shall not be attached to a surface coated with alkaline-base paint, embedded in concrete or masonry, or installed in a location subject to excessive moisture.

(E) Aluminum clamps and connectors, including bimetal types, shall conform in dimensions and strength to the requirements already specified for installations usmg copper.