Industrial Plant Design/System Planning/Determination of Loads

Determination of Loads

While the authors have used good faith and efforts to ensure that the information and instructions contained in this work are accurate, the authors disclaim all responsibility for errors or omissions, including without limitation responsibility for damages resulting from the use of or reliance on this work. Use of the information and instructions contained in this work is at your own risk. If any contents or other technology this work contains or describes is subject to open source licenses or the intellectual property rights of others, it is your responsibility to ensure that your use thereof complies with such licenses and/or rights.

Note: This is a work in progress...

General

Determination of the load is the Electrical Engineer's first problem and may be difficult to solve. The size and number of primary and secondary substations, the size, number, and arrangement of primary feeders, and the type of secondary distribution are largely dependent on the amount and nature of the load and its distribution.

The plant distribution system usually must be designed before all loads are known. This is at a time when the equipment layout itself is only in the formative stage. Equipment may be bought piecemeal during which time changes in machines are taking place either in number or size. Ideas are changed by the impact of what is commercially available, or manufacturers’ recommendations for improved models, better ways of securing a given result, or competitive conditions. Manufacturing processes are being changed as available equipment is fitted into the prospective production schedule.

Many plants are built to manufacture new products, which adds to the difficulty of establishing power requirements. Plant layouts are subject to considerable modification of the original scheme. Entire plant rearrangement may be necessary in the middle of a job; air and refrigerating compressors, fans, blowers, and pumps may come into the picture or shift position rapidly oil-fired annealing furnaces may become electrically heated as a result of laboratory tests that prove a controlled atmosphere necessary, thus adding hundreds if not thousands of kilowatts to the plant load.

Even after a plant is in operation, loads may change in size and location. New models, new products, and production methods call for continual change in the distribution system, bu. These changes can be minimized by careful planning.

Preliminary Loads

Preliminary estimates of loads is a problem deserving the closest study. These estimates may have to be used as the basis for major decisions. At this stage in the plant design, the Electrical Engineer often has available only a few building layout drawings or perhaps a plant map. The general locations of the major pieces of equipment will usually be roughly indicated and their power requirements may or may not be known. Starting with this information the Electrical Engineer must call on all his knowledge and experience as well as on that of other plant engineers and designers to enable him to arrive at an estimate which will stand up as the loads become better defined. In most cases, it is better to consider the lighting and power loads separately and combine them later to determine the demand in any one area, since present practice is usually to supply these loads from a load-center substation.

The factors most frequently used in determining distribution system loads are as follows:

- Demand Factor

- The ratio of the maximum demand on a system to the total connected load of the system. The maximum demand is usually the integrated maximum kilowatt demand over a 15 or 30-minute interval, rather than the instantaneous or peak demand.

- Diversity Factor

- The ratio of the sum of the individual maximum demands of the various parts of a system to the maximum demand of the whole system.

- Load Factor

- The ratio of the average load over a designated period of time to the peak load occurring in that period.

Information on the demand and the diversity factors for the various loads and groups of loads is needed to design the system. For example, the sum of the connected loads on a branch load circuit, multiplied by the demand factor of these loads, will give the maximum demand that the branch circuit must carry.

The sum of the maximum demands of the branch circuits associated with a sub-load center or panelboard divided by the diversity factor of those branch circuits will give the maximum demand at the sub-load center and on the circuit supplying it.

The sum of the maximum demands of the circuits radiating from a load center, divided by the diversity factor of those circuits, will give the maximum demand on the transformer at the load center. The sum of the maximum demands of the load-center transformers divided by the diversity factor of the transformer loads will give the maximum demand on their primary feeder. With the use of the proper demand and diversity factors as outlined above, the maximum demands on the various parts of the system from the branch load circuits to the power source can be determined.

Lighting Loads

Estimating the lighting is usually not difficult. For rough estimates, only the area of the building and the illumination level desired need be known. For more accurate estimating, the general type of construction must be known as well as mounting height and spacing and location of roof trusses and columns, so that the optimum arrangement can be checked against physical requirements. The intensity of illumination and the type of lighting (mercury, fluorescent, or incandescent) desired together with general construction features will make possible computation of load using formulas in lighting handbooks or data from fixture manufacturers.

For quick estimates of lighting with the most efficient fluorescent units, approximately three watts per square foot will provide 50-footcandle illumination. If incandescent lamps are used, the wattage will be approximately twice as much.

Information on outdoor lighting is readily available. Fence lighting can be estimated at 200 watts per 100 feet. "Yard lighting" is often adequate if a 200watt lamp is placed every 100 feet along the exterior walls of buildings. The total outdoor lighting will seldom exceed 25 percent of all lighting and it may be as little as 5 percent; hence, a rather nominal allowance in primary substation and feeder capacity will provide for considerable leeway for changes in the outdoor lighting which may develop late in the construction period.

Table 1.1 gives lighting requirements in various industries.

| Industry | Lighting in percent of the Total Connected Load (Percent) |

|---|---|

| Steel Foundries | 1 to 3 |

| Steel Rolling Mills, Oil Refining | 3 to 5 |

| Heavy Electric Equipment, Wire Drawing | 5 to 8 |

| Auto Equipment, Baking | 8 to 10 |

| Machine Parts | 10 to 15 |

| Auto Assembly and Parts | 15 to 25 |

The diversity factor of lighting load will be low and the demand factor of the lighting connected to any load center should be considered as 100 percent.

Power Loads

Estimating power loads is considerably more difficult that estimating the lighting load. Table 1. gives estimated load densities in representative industries.

| Type of Plant | Volt-Ampere Demand Light and Power (VA/sq.ft) |

|---|---|

| Airplane Factories | 15 to 25 |

| Beer, Sugar Factory and Refinery | 19 |

| Paper Mills | 14 |

| Textile Mills, Engine Builders | 12 |

| Cigarette Manufacturing | 11 |

| General Manufacturing, Chemicals, Electronic Equipment | 10 |

| Small Appliance Manufacturing, Machine Repair Shop | 7.5 |

| Lamp Manufacturing | 5 |

| Small Device Manufacturing | 3.5 |

Table 1.2 should be used for preliminary estimating only since the size of the plant and its processes will vary considerably within a given industry category.

Estimating Demand Factors of Various Loads

When the loads of individual machines or areas are known, it is necessary to combine them to obtain the maximum demand. The maximum demand determines the system capacity which must be provided to supply it as well as optimum system voltage, It is determined by applying demand and diversity factors to the connected load, The selection of demand and diversity factors, like load density, is based on known conditions, experience, and similar operations in existing plants. Table 1.3 gives the factors for the more common types of manufacturing loads and is the factor by which the connected load must be multiplied to obtain total plant demand assuming diversity factor of one, If the diversity factor is known, the demand thus obtained should be divided by the diversity factor to obtain the actual demand.

| Load | Estimating Demand Factors (Percent) |

|---|---|

| Arc Furnaces | 100 |

| Arc Welders | 30 |

| Induction Furnaces | 80 |

| Lighting | 100 |

| Motors | |

| 1. General Purpose, Machine Tool, Crane Elevators, Ventilation, Compressors, Pumps, Rolling Mills, etc. | 30 |

| 2 Small Appliance Manufacturing, Machine Repair Shop | 60 |

| 3. Continuous Operations Textile Mills, Chemical Plants, etc. | 90 |

| Resistance Ovens, Heaters and Furnaces | 80 |

| Resistance Welders | 20 |

As the table shows, the demand factor will vary considerably with different types of loads. For example, the demand factor of a group of motors driving a conveyor belt will approach 100 percent, while the demand factor of a group of hand tools in a small furniture factory or machine shop might be only 10 percent A diversity factor of unity is often used to provide ample system capacity, since the margin provided in this way is soon used by load growth. Although a diversity factor of unity represents the sum of the maximum demands of the individual load centers and of the equipment applied at the distribution voltage on the distribution system, the usual practice is to provide a system adequate for a maximum demand obtained with a diversity factor of unity or to provide even more than 100 percent capacity in the main system to take care of load centers which would be added in the future.

Power Requirement Per Bulk Product Weight

Any of a wide variety of plants may come under consideration in making a load survey. A knowledge of approximate KVA load necessary to produce unit weights of the material being made is a great help. This knowledge may come from past experience or available published material. It would be impossible to list all types of industries here, but requirements for some of the more important industries follow:

| Product | KilowattHours per Pound of Product |

|---|---|

| Gasoline | 0.0015 |

| Liquid Sulphur Dioxide | 0.002 |

| Glycerene | 0.007 |

| Ammonium Phosphate | 0.007 |

| Sulphuric Acid | 0.016 |

| Formaldehyde | 0.030 |

| Tri-Sodium Phosphate | 0.038 |

| Portland Cement | 0.050 |

| Ethylene Oxide | 0.070 |

| Alumina (ex. Bauxite) | 0.090 |

| Nitric Acid | 0.180 |

| Synthetic Ethyl Alcohol | 0.300 |

| Electric Steel | 0.330 |

| Carbon Disulphide | 0.450 |

| Benzene Hexachloride | 0.600 |

| Ammonia, Chlorine & Caustic | 0.750 |

| Phosphoric Acid | 1.80 |

| Rayon | 2.50 |

| Sodium | 4.70 |

| Hydrogen Peroxide, Electrolytic Magnesium | 8.0 |

| Aluminum | 9.0 |

| Product | kWH | Unit Product |

|---|---|---|

| Automobiles | 1050 | each |

| Cement | 22 | bbl |

| Wood Pulp | 384 | ton |

| Paper & Board | 575 | ton |

| Pig Iron | 25 | ton |

| Shoes | 472 | 1000 pairs |

| Steel | 227 | ton |

| Beet Sugar | 154 | tons of refined sugar |

| Sugar Cane | 220 | tons of raw sugar |

| Cigarettes | 200 | million |

| Cigars | 8100 | million |

Data Processing Centers

Large computers require that special consideration be given to the electric distribution system supplying them. Special requirements are usually stipulated by the computer manufacturer, and requirements vary with computer design.

A typical computer will require 3-phase, 4-wire, 60 Hz supply at 208, 230 or 240 volts. Permissible voltage variation ranges from ±3 to ±10 percent, depending on computer design. Frequency variations permitted are in the order of ±1/2 to ±1 Hz. Computers in general are liable to be damaged by system transients which may otherwise go undetected. The degree of sus- ceptibility varies with the computer design. It is always advisable to feed the computer from a separate transfor- mer, and in some cases it is necessary to isolate it further by the use of a motor-generator set.

Power requirements of typical large computer systems range from about 200 to 500 kva, with air-conditioning requirements of from 25 to 75 kva.

Trends in Design of Industrial Power Systems

Trends Affecting Power System Arrangements

Three important trends in the design of industrial systems which affect power system arrangement are:

- the increased use of load-center systems,

- the grounding of the system neutral at all voltage levels, and

- the increased use of higher voltages (generally 460Y / 265 volts) for lighting in industrial and commercial buildings.

These three trends are reviewed below:

Load-Center Systems

A load-center system may be defined as one in which power is transmitted at voltages above 600 volts to unit substations located close to the centers of electric load. At these substations the voltage is stepped down to the utilization level and distributed by short secondary feeders to the points of use. The trend to this type of system as opposed to older types of systems has become very marked in recent years. An examination of the advantages listed below for the load-center system when compared to older systems will indicate why such a trend has come about.

- Lower first cost.

- Reduced power losses.

- Improved voltage regulation.

- Increased flexibility.

- Better continuity of service.

- Simplified engineering, planning, and purchasing.

- Lower field installation expense.

- Higher salvage value,

Load-center systems may employ any of the basic system arrangements for primary power supply. The five combinations most generally used are radial, secondary selective, primary selective, looped primary and secondary network. What system to use must be determined by a study of the requirements for each job. Various other types of system arrangements, such as primary network, have been used as well as combinations of the basic system arrangements, such as primary selective—secondary selective. It should also be pointed out that a contributing factor to the increased use of load center systems has been the development of air circuit breakers, metal-clad and metal-enclosed switchgear, oil-filled and dry type transformers. These equipment have permitted the installation of the unit substations in buildings and close to the centers of loads without requiring ex- pensive vaults to minimize fire hazards and danger to personnel. Another factor has been use of the trans- former and large motor scheme, switched and protected as a unit.

System Neutral Grounding

Grounding of system neutrals at primary voltages has been almost universally practiced. However, there have always been two schools of thought regarding grounding of system neutrals at utilization voltages. There are many systems in-operation with ungrounded neutrals, but few such systems are being installed today. There is therefore, a trend toward neutral grounding at the lower voltages, and it is probable that most of the new systems from now on will be of the grounded-neutral type. The advantages claimed for system neutral grounding are:

- Reduced operating expense.

- Improved service reliability.

- Greater safety.

- Better system and equipment overcurrent protection.

- Improved lightning protection.

The use of grounded-neutral systems affects power system design by requiring, through study and careful selection, a means of grounding. Selection of transformers of proper characteristics for the unit substations will usually be involved. In some cases lower rated lightning arresters ‘may be used resulting in better surge protection. Ground relays are usually employed on high and medium voltage systems for faster relaying of faults.

High Voltage Lighting

The use of higher-voltage lighting, such as 460Y/265 volts, is gaining favor for large industrial and commercial buildings. Fluorescent and mercury-vapor lamps which require ballasts or transformers regardless of supply voltage are well adapted to operation on the higher voltages. Reduction of the total installed cost is the principal objective. The savings to be made are a function of the size of the building and the percentage of the total load connected to the higher voltage.

Higher voltage lighting will affect the design of the power system ‘ by reducing the number and size of low voltage feeders operating at 120 volts, although it will not be practicable to eliminate such circuits entirely due to the need for convenience outlets for appliances. Likewise, step-down transformers from 480 to 120 volts will also be reduced in number and size. Where the lighting is of the incandescent type and more than half the load it may not be economical to use higher-voltage lighting, since incandescent lamps require transformers to permit their operation on lower voltages.

Trends Affecting Power System Equipment Application

The principal trends that affect equipment in the industrial power system include:

Metal-Enclosed Switchgear Assemblies

The high cost of construction labor in recent years has emphasized the need for purchasing factory-assembled equipment if maximum economy is to be achieved. This need plus the many unquestionable advantages of metal-enclosed switchgear has accelerated the trend toward its use in plants recently built or in the process of building.

Three types of metal-enclosed switchgear have evolved over a span of 35 years since this type of equipment was first introduced to the industry. The distinction between types is based on construction features and voltage classification. Metal-enclosed switchgear is available in either indoor or outdoor construction.

Metal-clad Medium Voltage Switchgear

Metal-clad switchgear consists of completely metal-enclosed, grounded stationary structures in which the secondary control devices, main power bus and outgoing circuits are each isolated by means of grounded metal barriers to provide maximum reliability. The circuit interrupting devices are of the removable type and the buses, connections and joints are insulated throughout. Interlocks are provided to insure proper sequence and safe operation. Metal-clad switchgear is available for medium-voltage class systems.

Metal-enclosed Load-interrupter Switchgear

Metal-enclosed load-interrupter switchgear consists of completely metal-enclosed, grounded structures with fixed or removable fused (or non-fused) load-interrupter switches. No metal barriers are used to isolate separate parts of the primary circuit. Buses, joints and connectors are non-insulated copper or aluminum mounted on suitable supports. The fused load-interrupter switch is designed to interrupt load current, and should be capable of safely closing against high fault currents. The fault-interrupting capacity and the high-current closing capability of the equipment are dependent on the characteristics of the associated fuses. Suitable interlocks can be provided to insure safe and proper operation. Metal-enclosed load-interrupter switchgear is also available for low and medium voltage class systems.

Metal-enclosed Low-voltage Switchgear

Metal-enclosed low-voltage switchgear consists of free standing metal-enclosed, grounded switchboard structures with low-voltage power circuit breakers contained in individual compartments. The circuit breakers are either. stationary or draw-out mounted and may be controlled remotely (electrically operated) or from the front of the switchgear. The buses are normally non-insulated and in- coming and outgoing circuits are not normally barriered. Suitable interlocks are provided to insure safe and proper operation. As the name of this equipment implies, it is available for applications to low-voltage class systems.

Advantages of Metal Enclosed Switchgear

A few of the advantages of metal-enclosed switchgear are:

- Safety to personnel.

- Ease of maintenance.

- Ease of installation.

- Compactness.

- Lower installed cost.

- Flexibility.

- Ease of ordering.

Power Circuit Breakers

Air circuit breakers are now almost universally used as opposed to oil circuit breakers for a wide variety of voltages, current-carrying and interrupting capacities to cover almost every requirement in an industrial plant or commercial building. They have established a good record for reliability, safety, and low maintenance costs.

Oil-filled and Dry Type Transformers

The use of load-center systems has been facilitated by the development of transformers which can be installed in buildings close to centers of load without requiring ex- pensive vaults. The oil-filled transformer is the most commonly used type in the industrial field and has the broadest range of application. It has the advantages over the ventilated dry type of about twice the impulse strength, a lower audio sound level, lower maintenance, and can be located outdoors or almost anywhere in the plant.

At the present time dry type transformers are readily available in ratings up to 2000 kva at 15 kv and below. The cost of ventilated dry type transformers is about 10 to 15 percent above, that of conventional oil-insulated self-cooled transformers and is less than the cost of the askarel type. They are well adapted for use in clean locations.

Hermetically sealed dry type transformers filled with inert gas are available for use in less favorable locations. 35 to 40 percent more than the conventional oil-insulated self-cooled transformers. The hermetically sealed, Class H transformers, can be placed almost anywhere in a building provided adequate ventilation is available.

Cables

Rubber and rubber-like synthetic compounds used as insulation and cable coverings suitable for direct exposure to the elements and for direct burial in the ground are in common use at voltages up to 15 kv.

Synthetic compounds of the thermoplastic type such as poly-vinyl-chloride and polyethylene, are being used at an increasing rate for low-voltage power and control cable insulations because of the excellent electrical and moisture-resistant properties as well as their relatively low cost. Such insulations have made possible the use of these ) cables in trays.

Medium-voltage insulations require, in addition, high dielectric strength and corona and ozone resistance. Thermosetting synthetic compounds such as butyl, silicone, and rubber compounds are being used to meet these require- ments.

To protect insulating compounds which exhibit excellent electrical properties but lack the desired environmental resistance, neoprene compounds are being widely used for jacket material. Neoprene, a tough thermosetting synthet- ic compound, has a high resistance to chemicals likely to be encountered in service. :

On medium-voltage cables, shielding is normally used for voltages in excess of 4 kv except for portable cables , where shielding is normally used on cables above 2 kv.

The availability of the synthetic materials has created a trend away from underground duct systems and open wire on cross arms. Aerial cable, which is gradually replacing the duct and open-wire systems, is becoming quite popular for long outdoor circuits. Aerial cable is factory or field assembled from three or more properly insulated and jacketed conductors and a supporting messenger wire, which is effectively banded to the conductors. They are commonly made for voltages up to 15 kv grounded neutral and sizes up to 500 MCM. Advantages over the open-wire system are fewer service interruptions, good appearance, ease of installation, less congestion on poles or towers, improved voltage regulation because of lower and balanced reactance, and reduced clearance requirements.

For indoor and short outdoor circuits, interlocked armor cables have found wide application at all voltage levels up to 15 kv. This cable eliminates the need for conduit, raceways, or duct and is frequently installed in troughs, baskets or racks. To help insure a low ground return circuit impedance, an intersticial equipment ground wire is recommended and sometimes required by local Codes. It has been found that the interlocked armor exhibits an appreciable impedance which causes stray currents to flow through building members and may result in sparking and thus create a safety hazard, unless internal grounding conductors or other effective grounding circuit is provided.

Plugin Busway

The use of plug-in busway is quite common for indus-“trial buildings where changing loads must be accommodated. Factories, within which machines are likely to be moved around or changed frequently, provide excellent : applications for the plug-in busways. Although the first cost of such an installation may be higher, future changes can be je at much lower cost and in less time.

Capacitors

Shunt capacitors are used to advantage in many indus- trial installations. Electric power contracts frequently con- tain power-factor clauses which benefit the plant if reasonably high power factor is maintained. The savings realized will often pay for the installation cost of the capacitors within a short time. In addition, reduced voltage drop is realized, particularly if the capacitors are located near th loads. Likewise the power losses in feeders and branch circuits may be reduced because of lower currents flowing through them when the power factor is improved. This in turn achieves another benefit, the ability to carry additional connected load on the same feeder circuit.

Voltage Regulators

The spread in voltages supplied by the utilities, together with the voltage drops occurring in transformers, feeders, and branch circuits under load conditions, may result in a wide variation in voltage at the utilization devices between light load and heavy load conditions. The trend is to re- duce such voltage variations to a minimum in order to obtain more satisfactory operation of the power utilization devices, Some of the larger industrial plants install voltage regulators on. buses or feeders to maintain relatively constant voltages at the load. Transformers with load tap changing, have been used and are being increasingly applied when the incoming supply voltage is above 15 kv. While the trend is in the direction mentioned above, each case must be carefully studied to determine whether or not voltage correcting equipment can be economically justified.

Motor Control Centers

A strong trend has been established toward centralized motor control equipment. The advantages of grouping all motor controls at a central point are often present even when individual motor control units are used. Motor control centers have several advantages over individually mounted controllers. The most important advantages are:

- 1. Reduced installation costs.

- Complete units assembled and wired at the factory.

- 2. Flexibility.

- Because of modular type of construction, starters of various sizes can be readily interchanged on job.

- 3. Ease of maintenance.

- Starters may be removed for maintenance.

- 4. Increased safety.

- All units dead-front with interlocked doors.

- 5. Compactness.

- 6. Reduced engineering and purchasing costs.

- 7. Better protection against moisture, dirt, and mechanical injury.

- 8. Better appearance.

Prospective users of motor control centers should carefully study manufacturers’ specifications to ensure that the equipment offered will be adequate for the duty involved. Preference should be given. to standard construction. The economic advantage of motor control centers may be lost when special features are desired.

Single Line Diagrams

A single-line diagram indicates, using single lines and simplified symbols, the course and component devices or parts of an electric circuit or system of circuits.

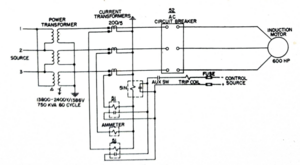

To illustrate, consider the simple circuit shown in Figure 1.4. This is a three-line diagram. It shows the details of an entire circuit. The complete paths of all currents can be traced through all the conductors and apparatus in the circuit.

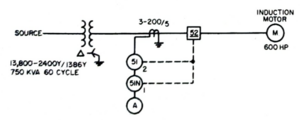

However, in a general consideration of such a circuit wherein we are ¥ concerned mainly with the path of energy transfer (but not current paths) and the identification of circuit components with their ratings, the single-line diagram, Figure 1.5 serves the purpose better.

In preparing preliminary plans for a system or specifications, it is not necessary to show all details in complete form on a one-line diagram. Some of the more important items to be included as follows:

- The available short-circuit and ground currents of the power company’s system.

- The size, type, and number of incoming and outgoing cables.

- The ratings, reactances, and connections of the transformers.

- The points at which power is to be metered and the type of metering desired.

- The amount and character of the load on all feeders.

- Authentic information as to the exact geographical location of the installation.

Figure 1.6 illustrates a preliminary one-line diagram of a typical industrial power system.

The following items, if given special attention during preparation, ensure complete, accurate, and lucid diagrams.

- 1. Keep the Diagram Simple

- The single-line diagram should show the major electric Circuits and components in the most simple form for ease of understanding. Equipment should be arranged to minimize the number of crossing lines without regard to the actual geometry of the plant. The geometry of the plant is of course important to keep in mind when making the one-line diagram. This geometry should be shown on a map, and a wiring diagram should be made later showing the actual location and routing of the circuits.

- 2. Avoid Duplication

- The one-line diagram is a sort of “diagram shorthand,” and for this reason, every line, symbol, figure, and letter has a definite meaning and is made to serve some definite purpose in conveying significant information. Therefore, duplication should be carefully avoided. For example, when giving the rating of a current transformer, the abbreviation “CT” should not be used because the symbol itself conveys this information, It is sufficient to state merely the type and rating, thus “800/5.” Even the abbreviation “AMP” after the rating is unnecessary because current transformers obviously can be rated only in amperes.

- 3. Use Standard Symbols

- The use of standard symbols and conventions is undesirable. If special features occur which cannot be accu- rately covered by standard symbols and conventions, care should be exercised to make entirely clear the meaning of any nonstandard symbol or convention devised to cover such features.

- 4. Show All Known Facts

- Details of circuits and devices known to the author of a diagram may seem to be unimportant or even irrelevant to him at the time, To someone else, however, or even to the author at a later date, these details may assume major importance, and their omission may be the cause of much extra work and loss of time, or even errors and misunderstandings. No detail within the scope of the diagram, therefore, should be considered as “unimportant,” and the rule, “when in doubt, show it,” should be followed.