VFD vs DOL Selection

Introduction

This article presents the criteria for the selection of the method of starting and operation of medium voltage motors.

The various criteria were presented and discussed for assessing the basis of selection of the recommended method of starting and operation of the motors.

Induction Motor Starting and Operation Method

The following two methods (options) for starting and operation of the motors were studied and evaluated:

- Direct Online Starting

- Variable Frequency Drive (VFD)

Direct-on-line (DOL) starter provides a simple and cost-effective way to start and stop motors. Theses are easy to install, operate and maintain. On the other hand, a variable frequency drive (VFD) offers a precise control over motor speed, allowing for energy savings and enhanced motor performance. VFDs are ideal for applications that require speed modulation or torque control.

To determine the best choice for the motor control needs, it is important to consider several factors. Understanding the advantages and limitations of both DOL starters and VFDs is crucial in making the right decision.

So, whether the requirement is a basic and economical motor control solution like DOL starters or require advanced features such as speed control and energy efficiency offered by VFDs, this article will weigh the pros and cons, ultimately serves as a guideline towards the best choice for the motor control requirements.

Selection Criteria

Direct-on-line (DOL) or Variable Frequency Drive (VFD) methods will be analyzed on given criteria provided herein. The analysis shall be performed on each criteria listing their respective strengths and weaknesses which will then be collectively weighted. The method of starting which will emerge as more beneficial to the project requirement shall be duly selected.

Some criteria to be considered during selection are:

- Operational Flexibility

- Production Efficiency

- Physical Dimension

- Life Cycle Cost and Economics

- Troubleshooting, Maintenance and Reliability

- Design and Motor Performance Impact

- Impact on Power Supply Network

- Energy Consumption and Sustainability

Operation Flexibility

DOL starter is a high risk to the motor due to its high starting current and has a very tight operating range to adapt to operating condition changes.

VFDs have a higher reliability and safety during motor start-ups. VFDs are more flexible to adapt to the changes in operating conditions.

Production Efficiency

DOL starter have a relatively lower production efficiency as it uses mechanical throttle device to control process flow, requires shutdown for transformer tap change, and has a narrow operating range to force motor to operate outside its operating range.

VFD is highly efficient in production as it used frequency adjustment to control process flow, no transformer tap change, no shutdown required for all well condition changes, and large operating range allowing motor to operate inside its permissible range hence extending motor life.

Physical Dimension

DOL starter comprises of two major components,

- Indoor Equipment,

- Outdoor Equipment.

The indoor equipment of DOL occupies less space than VFDs, however, DOL requires an additional space for an outdoor transformer while for VFDs the transformer is integral part of the indoor VFD equipment.

Life Cycle Cost and Economics

Initial Cost of Equipment

DOL starters have a lower initial equipment cost compared to VFDs. The initial investment cost for DOL starters is lower because they do not require complex electronics for motor control.

VFDs are generally more expensive upfront compared to the DOL starters due to the additional electronics and control mechanisms required for speed regulation. However, the potential energy savings and improved efficiency provided by VFDs can often justify the higher initial investment over the lifespan of the equipment.

Cost of Installation

DOL starter requires a larger area for the equipment footprint due to the outdoor equipment (i.e. power transformer) while VFD only requires a smaller area for its indoor equipment. Due to the larger footprint required to locate the outdoor equipment, the total cost of installation is higher for DOL.

Operation and Maintenance Cost

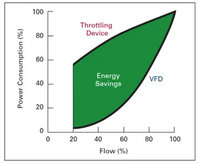

As the motor speed is fixed for a DOL, the energy consumption during the motor operation will remain constant. A mechanical throttling device (i.e. choke valve) is required to limit the flow in a variable flow process. Although this is an effective means of control, mechanical and electrical energy is wasted.

As VFD alters the power frequency to the motor, speed, flow, and energy consumption are reduced in the system. The comparative maintenance cost for DOL and VFD systems can vary based on several factors, including the complexity of the equipment, the operating environment, and the application requirements. The operating environment and application requirements for both systems will be the same hence comparative maintenance cost will be based on the complexity of the equipment.

DOL starters are relatively simple in design and have fewer components that can wear out or require regular servicing. However, DOL starters can experience high mechanical stress during motor startup due to the abrupt application of full voltage, which may lead to more frequent maintenance or replacement of ESP over time. The frequent maintenance or replacement of the motors makes the OPEX for DOL higher than VFD.

In addition, the moving parts of the conventional switching element need frequent inspection and maintenance. Failures in the moving parts of conventional circuit breakers due to an unusually high number of switchings are a phenomenon that increases the maintenance costs of DOL and may cause downtimes in production.

VFDs are complex electronic devices consisting of power electronics, control circuitry, and cooling systems. Maintenance requirements for VFDs may include periodic inspections, firmware updates, and replacement of components such as cooling fans, capacitors, and power modules. In addition, the requirement for skilled personnel to perform VFD maintenance tasks is essential.

VFDs are more susceptible to environmental factors and temperature fluctuations, which may require additional maintenance measures to ensure reliable operation. Proper regular preventive maintenance is crucial for maximizing the lifespan and reliability of VFDs.

Given the above, the operation and maintenance cost of DOL is higher than VFD.

Loss of Revenue

As there is wide uncertainty to evaluate the ESP performances which depend on reservoir conditions / well performance, considered loss of revenue is based on the following two cases: Case 1: Production Optimization Gain assuming well with water cut of 60 to 80 %, VFD can deliver additional production up to 500 to 1000 BPD production where as DOL can deliver up to 200 to 400 BPD. Case 2: Productivity loss by 50%, assuming water cut 60 to 80 %, VFD can maintain production of 500 to 1000 BPD where as DOL could be zero production due to potential ESP failure as it will be operating in downthrust conditions. In the above production scenarios, VFD can deliver higher production volume compared to DOL.

Troubleshooting, Maintenance and Reliability

DOL has a limited flexibility for troubleshooting related to well conditions compared to VFD which a better flexibility to changing well conditions. However, DOL is easier to troubleshoot due to lesser component in contrast to the complexity of a VFD.

Despite being easier to troubleshoot, DOL requires more maintenance, in particular the outdoor transformer. Based on actual site experience, VFDs are more reliable due to less breakdowns compare to DOL.

Impact on Power Supply Network

Adding high voltage motors on a system will impact the power supply network which underscores the importance of careful planning, monitoring, and management to ensure the reliable and efficient operation of the electrical network.

Starting Current

An motor starting directly from the switchboard supply creates a large starting current, which can be 6 to 9 times of the motor rated current. The large starting current generates a significant electrical stress on the power supply system. For a weak electrical network with a low X/R ratio, the high starting motor current may create significant voltage dip hence preventing the motor to reach its rated operating speed. In a worst case scenario, the voltage dip may exceed the limit for maximum allowable voltage drop which can cause the circuit breaker to trip. The high starting current allows the motor to deliver several times its rated torque. This can cause excessive electrical and mechanical stress on the equipment.

For example, an Electrical Submersible Pump is placed into operation at a depth that requires several hundred meters of power cable. During start-up operations, the cable causes a voltage drop to the motor, hence, the reduced voltage start decreases the initial starting current and torque.

Variable frequency drives (VFDs) offer smooth and soft motor starting characteristics. The motor starting current using a variable frequency drive can be reduced to ≤100% of the motor rated current. A lower starting current reduces the electrical stress on the supply and prevents it from significant voltage dips and unnecessary trips in the circuit breaker.

Harmonics

Harmonics refer to the frequencies that are integer multiples of the fundamental frequency. When harmonic frequencies are generated by non-linear loads within a power system, the voltage and current waveform will become distorted instead of a pure sinusoidal waveform. The distortion on the voltage and current waveform is called as harmonic distortion. Harmonic distortion is a measure of the amount of deviation from a pure sinusoidal waveform.

DOL electrical motor starters do not inherently produce harmonics. However, the operation of the motor connected to a DOL starter can introduce minimal harmonics into the power system due to voltage imbalance and mechanical resonance in the motor structure.

A VFD is a non-linear load hence will introduce harmonics into the electrical network creating harmonic distortion on the voltage and current waveform.

Harmonic distortions can affect the operation of other devices connected to the same power supply network. Various international standards have developed methods on how to assess the severity of harmonic distortion. One of these is standard IEEE 519 by the Institute of Electrical and Electronic Engineers (IEEE) which recognises that the sensitivity of the equipment to harmonics determines the acceptable level of voltage distortion. IEEE 519 states different limits for different types of installations, hence, variable frequency drives do not always include harmonic filtering.

As a rule of thumb, unless the variable frequency drives constitute more than 30% of the load on the transformer from which they receive power, there is little need to be concerned about harmonics and standard 6-pulse drives should be sufficient.

If harmonics are higher than desired after performing a harmonic analysis, there are a number of ways to mitigate the harmonic distortion like the use of filters or having a multipulse drives. These VFD configurations generate lower level of harmonic currents.

A study of industrial users identified harmonics as a contributor to economic losses. When compared to voltage sags, very rarely does harmonics distortion lead to a process interruption. Most of the costs are attributed to process slow down such as nuisance tripping. According to the report, 25% of the harmonic costs were related to equipment, either in the form of damage or additional maintenance.

The list below highlights the effects of excessive harmonics on equipment:

- Excessive temperature rise in motors and transformers.

- Sensitive electronic equipment malfunctions

- SCADA issues

- Accelerated aging of equipment

- Tripping of circuit breakers

- Cable insulation breakdown

Electromagnetic Interference

Electromagnetic interference (EMI) refers to the high frequency disturbance generated by electromagnetic radiation from an external source that disrupts the operation of an electronic device or system. This interference can degrade the performance of sensitive equipment, cause malfunctions, or even lead to complete system failure if not properly managed. EMI can be categorized into two types: conducted interference and radiated interference.

Conducted interference occurs when electromagnetic energy is conducted along power or signal cables and enters the device through its electrical connections. Common sources of conducted interference include power lines, motors, and switching power supplies. Radiated interference is caused by electromagnetic waves propagating through the air and inducing unwanted signals in nearby electronic devices. Radiated interference sources can include radio transmitters, mobile phones, and high-voltage power lines.

DOL can produce electromagnetic interference (EMI) during motor starting, although the extent and severity may vary depending on factors such as the size of the motor, the power supply system, and the surrounding environment.

The high inrush currents and voltage transients during motor starting are abrupt changes in current and voltage and can generate electromagnetic interference across a range of frequencies. However, this scenario only happens during the motor starting duration and not during normal motor operation.

Variable frequency drives (VFDs) produce electromagnetic interference (EMI) due to the switching action and the rapid changes in voltage and current they generate. The switching of power semiconductors within VFDs, such as insulated gate bipolar transistors (IGBTs) or power MOSFETs, can create high-frequency harmonics and noise that can interfere with nearby electronic equipment.

The layout and length of cables connected to the VFD can as well affect the amount of electromagnetic interference produced. Longer cables act as antennas, radiating electromagnetic energy, while improper cable routing can increase coupling with nearby sensitive equipment.

Switching Transients

An electrical transient occurs on a power system each time an abrupt circuit change occurs. This circuit change is usually the result of a normal switching operation, such as breaker opening or closing or simply turning a light switch on or off.

Switching transients are oscillatory and are characterized by their transient period, very short when compared with the power frequency. The duration of the transients is mostly in the range of microseconds to several milliseconds and depends on circuit parameters.

Transients are extremely important because at such times, the circuit components and electrical equipment are subjected to the greatest stresses resulting from abnormal transient voltages and currents. Transients cause over-voltage and overcurrent. Over-voltages caused may result in flashovers or insulation breakdown, while overcurrent may damage equipment due to electromagnetic forces and excessive heat generation. Flashovers usually cause temporary power outages due to tripping of the protective devices, but insulation breakdown usually leads to permanent equipment damage.

Switching occurs during the start – stop operation of the DOL. The sudden change in the system can initiate damped oscillations with high frequencies that depend on resonant frequencies of the network. Magnitude and duration of the switching overvoltages depends on many parameters such as type of the load and the switching device.

Overvoltages generated by the switching in power electronic converters are similar to the switching overvoltages in nature, with the difference that they occur continuously and with high frequencies. The frequency of the switching transient is determined by values of inductance, capacitance, and resistance.

The advancements in electronics have increased switching frequency while reducing the losses. VFDs have benefited from these fast switches in the form of higher flexibility and performance. On the downside, the major problems associated with these drives come from their three inherent features: the fast rise time of the pulses (or high dv/dt), the pulse repetition frequency, and the overvoltage.

In a VFD, the output voltage of the inverter is near square wave shaped. However, the voltage wave reflection phenomenon in a cable can create a high frequency overvoltages at the end of the cable that can exceed twice the DC link voltage. These high frequency voltage spikes, created by the interaction of the inverter and the cable, have some unfavorable effects on the components of the system.