Philippine Electrical Code 2009 Part 1/Chapter 2. Wiring and Protection/Article 2.50 - Grounding And Bonding: Difference between revisions

(No difference)

|

Revision as of 11:05, 22 February 2020

Article 2.50 - Grounding And Bonding

While the authors have used good faith and efforts to ensure that the information and instructions contained in this work are accurate, the authors disclaim all responsibility for errors or omissions, including without limitation responsibility for damages resulting from the use of or reliance on this work. Use of the information and instructions contained in this work is at your own risk. If any contents or other technology this work contains or describes is subject to open source licenses or the intellectual property rights of others, it is your responsibility to ensure that your use thereof complies with such licenses and/or rights.

Note: This is a work in progress...

2.50.1 General

2.50.1.1 Scope.

This article covers general requirements for grounding and bonding of electrical installations, and specific requirements in (1) through (6). (1) Systems, circuits, and equipment required, permitted, or not permitted to be grounded

(2) Circuit conductor to be grounded on grounded systems

(3) Location of grounding connections

(4) Types and sizes of grounding and bonding conductors and electrodes

(5) Methods of grounding and bonding

(6) Conditions under which guards, isolation, or insulation may be substituted for grounding

2.50.1.2 Definitions.

Effective Ground-Fault Current Path. An intentionally constructed, permanent, low-impedance electrically conductive path designed and intended to carry current under ground-fault conditions from the point of a ground fault on a wiring system to the electrical supply source and that facilitates the operation of the overcurrent protective device or ground fault detectors on high-impedance grounded systems.

Ground Fault. An unintentional, electrically conducting connection between an ungrounded conductor of an electrical circuit and the normally non–current-carrying conductors, metallic enclosures, metallic raceways, metallic equipment, or earth.

Ground-Fault Current Path. An electrically conductive path from the point of a ground fault on a wiring system through normally non– current-carrying conductors, equipment, or the earth to the electrical supply source.

FPN: Examples of ground-fault current paths could consist of any combination of equipment grounding conductors, metallic raceways, metallic cable sheaths, electrical equipment, and any other electrically conductive material such as metal water and gas piping, steel framing members, stucco mesh, metal ducting, reinforcing steel, shields of communications cables, and the earth itself.

2.50.1.3 Application of Other Articles.

In other articles applying to particular cases of installation of conductors and equipment, requirements are identified in Table 2.50.1.3 that are in addition to, or modifications of, those of this article.

2.50.1.4 General Requirements for Grounding and Bonding.

The following general requirements identify what grounding and bonding of electrical systems are required to accomplish. The prescriptive methods contained in Article 2.50 shall be followed to comply with the performance requirements of this section.

(a) Grounded Systems.

(1) Electrical System Grounding. Electrical systems that are grounded shall be connected to earth in a manner that will limit the voltage imposed by lightning, line surges, or unintentional contact with higher-voltage lines and that will stabilize the voltage to earth during normal operation.

(2) Grounding of Electrical Equipment. Non–current-carrying conductive materials enclosing electrical conductors or equipment, or forming part of such equipment, shall be connected to earth so as to limit the voltage to ground on these materials.

(3) Bonding of Electrical Equipment. Non–current-carrying conductive materials enclosing electrical conductors or equipment, or forming part of such equipment, shall be connected together and to the electrical supply source in a manner that establishes an effective ground-fault current path.

| Conductor/Equipment | Article | Section |

|---|---|---|

| Agricultural buildings | 5.47.1.9 and 5.47.1.10 | |

| Audio signal processing, amplification, and reproduction equipment | 6.40.1.7 | |

| Branch circuits | 2.10.1.5, 2.10.1.6, 4.6.1.3 | |

| Cablebus | 3.70.1.9 | |

| Cable trays | 3.92 | 3.92.1.3(c), 3.92.1.7 |

| Capacitors | 4.60.1.10, 4.60.2.4 | |

| Circuits and equipment operating at less than 50 volts | 7.20 | |

| Closed-loop and programmed power distribution | 7.80.1.3 | |

| Communications circuits | 8.0 | |

| Community antenna television and radio distribution systems | 8.20.3.1, 8.20.4.1, 8.20.4.4 | |

| Conductors for general wiring | 3.10 | |

| Cranes and hoists | 6.10 | |

| Electrically driven or controlled irrigation machines | 6.75.1.11(c), 6.75.1.12, 6.75.1.13, 6.75.1.14,6.75.1.15 | |

| Electric signs and outline lighting | 6.0 | |

| Electrolytic cells | 6.68 | |

| Elevators, dumbwaiters, escalators, moving walks, wheelchair lifts, and stairway chair lifts | 6.20 | |

| Fire alarm systems | 7.60.1.9 | |

| Fixed electric heating equipment for pipelines and vessels | 4.27.4.5, 4.27.6.4 | |

| Fixed outdoor electric deicing and snow- melting equipment | 4.26.3.8 | |

| Flexible cords and cables | 4.0.2.3, 4.0.2.4 | |

| Floating buildings | 5.53.3.1, 5.53.3.3, 5.53.3.4 | |

| Grounding-type receptacles, adapters, cord connectors, and attachment plugs | 4.6.1.9 | |

| Hazardous (classified) locations | 5.0–5.17 | |

| Health care facilities | 5.17 | |

| Induction and dielectric heating equipment | 6.65 | |

| Industrial machinery | 6.70 | |

| Information technology equipment | 6.45.1.15 | |

| Intrinsically safe systems | 5.4.1.50 | |

| Luminaires (lighting fixtures) and lighting equipment | 4.10.5.1, 4.10.5.2, 4.10.5.4, 4.10.5.5,4.10.15.6(b) | |

| Luminaires (fixtures), lampholders, and lamps | 4.10 | |

| Marinas and boatyards | 5.55.1.15 | |

| Mobile homes and mobile home park | 5.50 | |

| Motion picture and television studios and similar locations | 4.30 | 5.30.2.10, 5.30.6.4(b) |

| Motors, motor circuits, and controllers | 6.50 | |

| Outlet, device, pull, and junction boxes; conduit bodies; and fittings | 8.10 | 3.14.1.4, 3.14.2.11 |

| Over 600 volts, nominal, underground wiring methods | 5.51 | 3.0.2.20(b) |

| Panelboards | 2.30 | 4.8.3.11 |

| Pipe organs | 6.80 | |

| Radio and television equipment | ||

| Receptacles and cord connectors | 4.6.1.3 | |

| Recreational vehicles and recreational vehicle parks | ||

| Services | ||

| Solar photovoltaic systems | 6.90.5.1, 6.90.5.2, 6.90.5.3, 6.90.5.5, 6.90.5.7 | |

| Swimming pools, fountains, and similar installations | ||

| Switchboards and panelboards | 4.8.1.3(d) | |

| Switches | 4.4.1.12 | |

| Theaters, audience areas of motion picture and television studios, and similar locations | 5.20.7.1 | |

| Transformers and transformer vaults | 4.50.1.10 | |

| Use and identification of grounded conductors | 2.0 | |

| X-ray equipment | 6.60 | 5.17.5.8 |

(4) Bonding of Electrically Conductive Materials and Other Equipment. Electrically conductive materials that are likely to become energized shall be connected together and to the electrical supply source in a manner that establishes an effective ground-fault current path.

(5) Effective Ground-Fault Current Path. Electrical equipment and wiring and other electrically conductive material likely to become energized shall be installed in a manner that creates a permanent, low- impedance circuit facilitating the operation of the overcurrent device or ground detector for high-impedance grounded systems. It shall be capable of safely carrying the maximum ground-fault current likely to be imposed on it from any point on the wiring system where a ground fault may occur to the electrical supply source. The earth shall not be considered as an effective ground-fault current path.

(b) Ungrounded Systems.

(1) Grounding Electrical Equipment. Non–current-carrying conductive materials enclosing electrical conductors or equipment, or forming part of such equipment, shall be connected to earth in a manner that will limit the voltage imposed by lightning or unintentional contact with higher-voltage lines and limit the voltage to ground on these materials.

(2) Bonding of Electrical Equipment. Non–current-carrying conductive materials enclosing electrical conductors or equipment, or forming part of such equipment, shall be connected together and to the supply system grounded equipment in a manner that creates a permanent, low-impedance path for ground-fault current that is capable of carrying the maximum fault current likely to be imposed on it.

(3) Bonding of Electrically Conductive Materials and Other Equipment. Electrically conductive materials that are likely to become energized shall be connected together and to the supply system grounded equipment in a manner that creates a permanent, low- impedance path for ground-fault current that is capable of carrying the maximum fault current likely to be imposed on it.

(4) Path for Fault Current. Electrical equipment, wiring, and other electrically conductive material likely to become energized shall be installed in a manner that creates a permanent, low-impedance circuit from any point on the wiring system to the electrical supply source to facilitate the operation of overcurrent devices should a second fault occur on the wiring system. The earth shall not be considered as an effective fault-current path.

FPN No. 1: A second fault that occurs through the equipment enclosures and bonding is considered a ground fault.

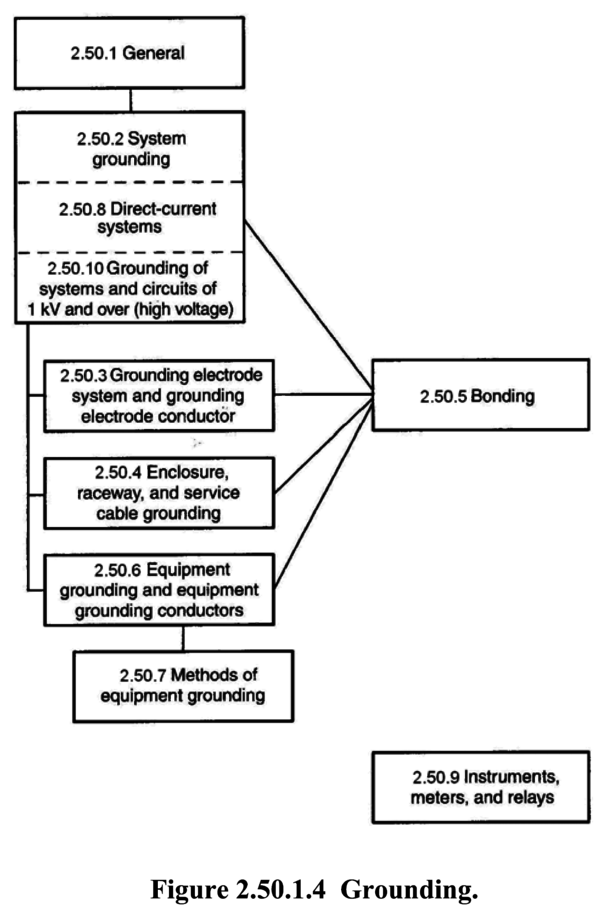

FPN No. 2: See Figure 2.50.1.4 for information on the organization of Article 2.50.

2.50.1.6 Objectionable Current over Grounding Conductors.

(a) Arrangement to Prevent Objectionable Current. The grounding of electrical systems, circuit conductors, surge arresters, and conductive non–current-carrying materials and equipment shall be installed and arranged in a manner that will prevent objectionable current over the grounding conductors or grounding paths.

(b) Alterations to Stop Objectionable Current. If the use of multiple grounding connections results in objectionable current, one or more of the following alterations shall be permitted to be made, provided that the requirements of 2.50.1.4(a)(5) or (b)(4) are met:

- (1) Discontinue one or more but not all of such grounding connections.

- (2) Change the locations of the grounding connections.

- (3) Interrupt the continuity of the conductor or conductive path interconnecting the grounding connections.

- (4) Take other suitable remedial and approved action.

(c) Temporary Currents Not Classified as Objectionable Currents. Temporary currents resulting from accidental conditions, such as ground-fault currents, that occur only while the grounding conductors are performing their intended protective functions shall not be classified as objectionable current for the purposes specified in 2.50.1.6(a) and (b).

(d) Limitations to Permissible Alterations. The provisions of this section shall not be considered as permitting electronic equipment from being operated on ac systems or branch circuits that are not grounded as required by this article. Currents that introduce noise or data errors in electronic equipment shall not be considered the objectionable currents addressed in this section.

(e) Isolation of Objectionable Direct-Current Ground Currents. Where isolation of objectionable dc ground currents from cathodic protection systems is required, a listed ac coupling/dc isolating device shall be permitted in the equipment grounding path to provide an effective return path for ac ground-fault current while blocking dc current.

2.50.1.8 Connection of Grounding and Bonding Equipment.

Grounding conductors and bonding jumpers shall be connected by exothermic welding, listed pressure connectors, listed clamps, or other listed means. Connection devices or fittings that depend solely on solder shall not be used. Sheet metal screws shall not be used to connect grounding conductors or connection devices to enclosures.

2.50.1.10 Protection of Ground Clamps and Fittings. =

Ground clamps or other fittings shall be approved for general use without protection or shall be protected from physical damage as indicated in (1) or (2) as follows:

- (1) In installations where they are not likely to be damaged

- (2) Where enclosed in metal, wood, or equivalent protective covering 2.50.1.12 Clean Surfaces. Nonconductive coatings (such as paint, lacquer, and enamel) on equipment to be grounded shall be removed from threads and other contact surfaces to ensure good electrical continuity or be connected by means of fittings designed so as to make such removal unnecessary.

2.50.2 System Grounding

2.50.2.1 Alternating-Current Systems to Be Grounded.

Alternating-current systems shall be grounded as provided for in 2.50.2.1(a), (b), (c), or (d). Other systems shall be permitted to be grounded. If such systems are grounded, they shall comply with the applicable provisions of this article.

FPN: An example of a system permitted to be grounded is a corner-grounded delta transformer connection. See 2.50.2.7(4) for conductor to be grounded.

(a) Alternating-Current Systems of Less Than 50 Volts. Alternating-current systems of less than 50 volts shall be grounded under any of the following conditions:

- (1) Where supplied by transformers, if the transformer supply system exceeds 150 volts to ground

- (2) Where supplied by transformers, if the transformer supply system is ungrounded

- (3) Where installed as overhead conductors outside of buildings

(b) Alternating-Current Systems of 50 Volts to 1000 Volts.

Alternating-current systems of 50 volts to 1000 volts that supply premises wiring and premises wiring systems shall be grounded under any of the following conditions:

- (1) Where the system is 1-phase and can be grounded so that the maximum voltage to ground on the ungrounded conductors does not exceed 250 volts

- (2) Where the system is 3-phase, 4-wire, wye connected in which the neutral is used as a circuit conductor

- (3) Where the system is 3-phase, 4-wire, delta connected in which the midpoint of one phase winding is used as a circuit conductor

(c) Alternating-Current Systems of 1 kV and Over. Alternating- current systems supplying mobile or portable equipment shall be grounded as specified in 2.50.10.9. Where supplying other than mobile or portable equipment, such systems shall be permitted to be grounded.

(d) Separately Derived Systems. Separately derived systems, as covered in 2.50.2.1(a) or (b), shall be grounded as specified in 2.50.2.11.

FPN No. 1: An alternate ac power source such as an on-site generator is not a separately derived system if the neutral is solidly interconnected to a service- supplied system neutral.

FPN No. 2: For systems that are not separately derived and are not required to be grounded as specified in 2.50.2.11, see 4.45.1.13 for minimum size of conductors that must carry fault current.

(e) Impedance Grounded Neutral Systems. Impedance grounded neutral systems shall be grounded in accordance with 2.50.2.17 or 2.50.10.7.

2.50.2.2 Alternating-Current Systems of 50 Volts to 1000 Volts Not Required to Be Grounded.

The following ac systems of 50 volts to 1000 volts shall be permitted to be grounded but shall not be required to be grounded:

(1) Electric systems used exclusively to supply industrial electric furnaces for melting, refining, tempering, and the like

(2) Separately derived systems used exclusively for rectifiers that supply only adjustable-speed industrial drives

(3) Separately derived systems supplied by transformers that have a primary voltage rating less than 1000 volts, provided that all the following conditions are met:

- a. The system is used exclusively for control circuits.

- b. The conditions of maintenance and supervision ensure that only licensed electrical practitioner or non licensed electrical practitioner under the supervision of a licensed electrical practitioner service the installation.

- c. Continuity of control power is required.

- d. Ground detectors are installed on the control system.

(4) Other systems that are not required to be grounded in accordance with the requirements of 2.50.2.1(b). Where an alternating-current system is not grounded as permitted in 2.50.2.2(1) through (4), ground detectors shall be installed on the system.

Exception: Systems of less than 120 volts to ground as permitted by this Code shall not be required to have ground detectors. 2.50.2.3 Circuits Not to Be Grounded. The following circuits shall not be grounded:

- (1) Circuits for electric cranes operating over combustible fibers in Class III locations, as provided in 5.3.3.56.

- (2) Circuits in health care facilities as provided in 5.17.4.2 and 5.17.7.1

- (3) Circuits for equipment within electrolytic cell working zone as provided in Article 6.68

- (4) Secondary circuits of lighting systems as provided in 4.11.1.5(a)

2.50.2.5 Grounding Service-Supplied Alternating-Current Systems.

(a) System Grounding Connections. A premises wiring system supplied by a grounded ac service shall have a grounding electrode conductor connected to the grounded service conductor, at each service, in accordance with 2.50.2.5(a)(1) through (a)(5).

(1) General. The connection shall be made at any accessible point from the load end of the service drop or service lateral to and including the terminal or bus to which the grounded service conductor is connected at the service disconnecting means.

FPN: See definitions of Service Drop and Service Lateral in Article 1.0.

(2) Outdoor Transformer. Where the transformer supplying the service is located outside the building, at least one additional grounding connection shall be made from the grounded service conductor to a grounding electrode, either at the transformer or elsewhere outside the building.

Exception: The additional grounding connection shall not be made on high-impedance grounded neutral systems. The system shall meet the requirements of 2.50.2.17.

(3) Dual Fed Services. For services that are dual fed (double ended) in a common enclosure or grouped together in separate enclosures and employing a secondary tie, a single grounding electrode connection to the tie point of the grounded conductor(s) from each power source shall be permitted.

(4) Main Bonding Jumper as Wire or Busbar. Where the main bonding jumper specified in 2.50.2.9 is a wire or busbar and is installed from the grounded conductor terminal bar or bus to the equipment grounding terminal bar or bus in the service equipment, the grounding electrode conductor shall be permitted to be connected to the equipment grounding terminal, bar, or bus to which the main bonding jumper is connected.

(5) Load-Side Grounding Connections. A grounding connection shall not be made to any grounded conductor on the load side of the service disconnecting means except as otherwise permitted in this article.

FPN: See 2.50.2.11(a) for separately derived systems, 2.50.2.13 for connections at separate buildings or structures, and 2.50.7.13 for use of the grounded circuit conductor for grounding equipment.

(b) Main Bonding Jumper. For a grounded system, an unspliced main bonding jumper shall be used to connect the equipment grounding conductor(s) and the service-disconnect enclosure to the grounded conductor within the enclosure for each service disconnect in accordance with 2.50.2.9.

Exception No. 1: Where more than one service disconnecting means is located in an assembly listed for use as service equipment, an unspliced main bonding jumper shall bond the grounded conductor(s) to the assembly enclosure.

Exception No. 2: Impedance grounded neutral systems shall be permitted to be connected as provided in 2.50.2.17 and 2.50.10.7.

(c) Grounded Conductor Brought to Service Equipment. Where an ac system operating at less than 1000 volts is grounded at any point, the grounded conductor(s) shall be run to each service disconnecting means and shall be bonded to each disconnecting means enclosure. The grounded conductor(s) shall be installed in accordance with 2.50.2.5(c)(1) through (c)(3).

Exception: Where more than one service disconnecting means are located in an assembly listed for use as service equipment, it shall be permitted to run the grounded conductor(s) to the assembly, and the conductor(s) shall be bonded to the assembly enclosure.

- (1) Routing and Sizing. This conductor shall be routed with the phase conductors and shall not be smaller than the required grounding electrode conductor specified in Table 2.50.3.17 but shall not be required to be larger than the largest ungrounded service-entrance phase conductor. In addition, for service-entrance phase conductors larger than 1100 kcmil copper or 850 mm2 aluminum, the grounded conductor shall not be smaller than 12½ percent of the area of the largest service-entrance phase conductor. The grounded conductor of a 3-phase, 3-wire delta service shall have an ampacity not less than that of the ungrounded conductors.

- (2) Parallel Conductors. Where the service-entrance phase conductors are installed in parallel, the size of the grounded conductor shall be based on the total circular mil area of the parallel conductors as indicated in this section. Where installed in two or more raceways, the size of the grounded conductor in each raceway shall be based on the size of the ungrounded service-entrance conductor in the raceway but not smaller than 50 mm2.

FPN: See 3.10.1.4 for grounded conductors connected in parallel.

- (3) High Impedance. The grounded conductor on a high- impedance grounded neutral system shall be grounded in accordance with 2.50.2.17.

(d) Grounding Electrode Conductor. A grounding electrode conductor shall be used to connect the equipment grounding conductors, the service-equipment enclosures, and, where the system is grounded, the grounded service conductor to the grounding electrode(s) required by Part 2.50.3. High-impedance grounded neutral system connections shall be made as covered in 2.50.2.17.

FPN: See 2.50.2.5(a) for ac system grounding connections.

(e) Ungrounded System Grounding Connections. A premises wiring system that is supplied by an ac service that is ungrounded shall have, at each service, a grounding electrode conductor connected to the grounding electrode(s) required by Part 2.50.3. The grounding electrode conductor shall be connected to a metal enclosure of the service conductors at any accessible point from the load end of the service drop or service lateral to the service disconnecting means.

2.50.2.7 Conductor to Be Grounded — Alternating-Current Systems.

For ac premises wiring systems, the conductor to be grounded shall be as specified in the following:

(1) Single-phase, 2-wire — one conductor

(2) Single-phase, 3-wire — the neutral conductor

(3) Multiphase systems having one wire common to all phases — the common conductor

(4) Multiphase systems where one phase is grounded — one phase conductor

(5) Multiphase systems in which one phase is used as in (2) — the neutral conductor

2.50.2.9 Main Bonding Jumper and System Bonding Jumper.

For a grounded system, main bonding jumpers and system bonding jumpers shall be installed as follows:

(a) Material. Main bonding jumpers and system bonding jumpers shall be of copper or other corrosion-resistant material. A main bonding jumper and a system bonding jumper shall be a wire, bus, screw, or similar suitable conductor.

(b) Construction. Where a main bonding jumper or a system bonding jumper is a screw only, the screw shall be identified with a green finish that shall be visible with the screw installed.

(c) Attachment. Main bonding jumpers and system bonding jumpers shall be attached in the manner specified by the applicable provisions of 2.50.1.8.

(d) Size. Main bonding jumpers and system bonding jumpers shall not be smaller than the sizes shown in Table 2.50.3.17. Where the supply conductors are larger than 1100 kcmil copper or 850 mm2 aluminum, the bonding jumper shall have an area that is not less than 12½ percent of the area of the largest phase conductor except that, where the phase conductors and the bonding jumper are of different materials (copper or aluminum), the minimum size of the bonding jumper shall be based on the assumed use of phase conductors of the same material as the bonding jumper and with an ampacity equivalent to that of the installed phase conductors.

2.50.2.11 Grounding Separately Derived Alternating-Current Systems.

(a) Grounded Systems. A separately derived ac system that is grounded shall comply with 2.50.2.11(a)(1) through (a)(8). A grounding connection shall not be made to any grounded circuit conductor on the load side of the point of grounding of the separately derived system except as otherwise permitted in this article.

FPN: See 2.50.2.13 for connections at separate buildings or structures, and 2.50.7.13 for use of the grounded circuit conductor for grounding equipment.

Exception: Impedance grounded neutral system grounding connections shall be made as specified in 2.50.2.17 or 2.50.10.7.

(1) System Bonding Jumper. An unspliced system bonding jumper in compliance with 2.50.2.9(a) through (d) that is sized based on the derived phase conductors shall be used to connect the equipment grounding conductors of the separately derived system to the grounded conductor. This connection shall be made at any single point on the separately derived system from the source to the first system disconnecting means or overcurrent device, or it shall be made at the source of a separately derived system that has no disconnecting means or overcurrent devices.

Exception No. 1: For separately derived systems that are dual fed (double ended) in a common enclosure or grouped together in separate enclosures and employing a secondary tie, a single system bonding jumper connection to the tie point of the grounded circuit conductors from each power source shall be permitted.

Exception No. 2: A system bonding jumper at both the source and the first disconnecting means shall be permitted where doing so does not establish a parallel path for the grounded conductor. Where a grounded conductor is used in this manner, it shall not be smaller than the size specified for the system bonding jumper but shall not be required to be larger than the ungrounded conductor(s). For the purposes of this exception, connection through the earth shall not be considered as providing a parallel path.

Exception No. 3: The size of the system bonding jumper for a system that supplies a Class 1, Class 2, or Class 3 circuit, and is derived from a transformer rated not more than 1000 volt-amperes, shall not be smaller than the derived phase conductors and shall not be smaller than 2.0 mm2 (1.6 mm dia.) copper or 3.5 mm2 (2.0 mm dia.) aluminum.

(2) Equipment Bonding Jumper Size. Where a bonding jumper of the wire type is run with the derived phase conductors from the source of a separately derived system to the first disconnecting means, it shall be sized in accordance with 2.50.5.13(c), based on the size of the derived phase conductors.

(3) Grounding Electrode Conductor, Single Separately Derived System. A grounding electrode conductor for a single separately derived system shall be sized in accordance with 2.50.3.17 for the derived phase conductors and shall be used to connect the grounded conductor of the derived system to the grounding electrode as specified in 2.50.2.11(a)(7). This connection shall be made at the same point on the separately derived system where the system bonding jumper is installed.

Exception No. 1: Where the system bonding jumper specified in 2.50.2.11(a)(1) is a wire or busbar, it shall be permitted to connect the grounding electrode conductor to the equipment grounding terminal, bar, or bus, provided the equipment grounding terminal, bar, or bus is of sufficient size for the separately derived system.

Exception No. 2: Where a separately derived system originates in listed equipment suitable as service equipment, the grounding electrode conductor from the service or feeder equipment to the grounding electrode shall be permitted as the grounding electrode conductor for the separately derived system, provided the grounding electrode conductor is of sufficient size for the separately derived system. Where the equipment ground bus internal to the equipment is not smaller than the required grounding electrode conductor for the separately derived system, the grounding electrode connection for the separately derived system shall be permitted to be made to the bus.

Exception No. 3: A grounding electrode conductor shall not be required for a system that supplies a Class 1, Class 2, or Class 3 circuit and is derived from a transformer rated not more than 1000 volt-amperes, provided the grounded conductor is bonded to the transformer frame or enclosure by a jumper sized in accordance with 2.50.2.11(a)(1), Exception No. 3, and the transformer frame or enclosure is grounded by one of the means specified in 2.50.7.5.

(4) Grounding Electrode Conductor, Multiple Separately Derived Systems. Where more than one separately derived system is installed, it shall be permissible to connect a tap from each separately derived system to a common grounding electrode conductor. Each tap conductor shall connect the grounded conductor of the separately derived system to the common grounding electrode conductor. The grounding electrode conductors and taps shall comply with 2.50.2.11(a)(4)a through (a)(4)c.

Exception No. 1: Where the system bonding jumper specified in 2.50.2.11(a)(1) is a wire or busbar, it shall be permitted to connect the grounding electrode conductor to the equipment grounding terminal, bar, or bus, provided the equipment grounding terminal, bar, or bus is of sufficient size for the separately derived system.

Exception No. 2: A grounding electrode conductor shall not be required for a system that supplies a Class 1, Class 2, or Class 3 circuit and is derived from a transformer rated not more than 1000 volt-amperes, provided the system grounded conductor is bonded to the transformer frame or enclosure by a jumper sized in accordance with 2.50.2.11(a)(1), Exception No. 3 and the transformer frame or enclosure is grounded by one of the means specified in 2.50.7.5.

a. Common Grounding Electrode Conductor Size. The common grounding electrode conductor shall not be smaller than 80 mm2 copper or 125 mm2 aluminum.

b. Tap Conductor Size. Each tap conductor shall be sized in accordance with 2.50.3.17 based on the derived phase conductors of the separately derived system it serves.

Exception: Where a separately derived system originates in listed equipment suitable as service equipment, the grounding electrode conductor from the service or feeder equipment to the grounding electrode shall be permitted as the grounding electrode conductor for the separately derived system, provided the grounding electrode conductor is of sufficient size for the separately derived system. Where the equipment ground bus internal to the equipment is not smaller than the required grounding electrode conductor for the separately derived system, the grounding electrode connection for the separately derived system shall be permitted to be made to the bus.

c. Connections. All tap connections to the common grounding electrode conductor shall be made at an accessible location by one of the following methods:

- 1. A listed connector.

- 2. Listed connections to aluminum or copper busbars not less than 6 mm × 50 mm. Where aluminum busbars are used, the installation shall comply with 2.50.3.15(a).

- 3. By the exothermic welding process.

Tap conductors shall be connected to the common grounding electrode conductor in such a manner that the common grounding electrode conductor remains without a splice or joint.

(5) Installation. The installation of all grounding electrode conductors shall comply with 2.50.3.15(a), (b), (c), and (e).

(6) Bonding. Structural steel and metal piping shall be bonded in accordance with 2.50.5.15(d).

(7) Grounding Eletrode. The grounding electrode shall be as near as practicable to and preferably in the same area as the grounding electrode conductor connection to the system. The grounding electrode shall be the nearest one of the following:

- a. Metal water pipe grounding electrode as specified in 2.50.3.3(a)(1)

- b. Structural metal grounding electrode as specified in 2.50.3.3(a)(2)

Exception No. 1: Any of the other electrodes identified in 2.50.3.3(a) shall be used where the electrodes specified by 2.50.2.11(a)(7) are not available.

Exception No. 2 to (1) and (2): Where a separately derived system originates in listed equipment suitable for use as service equipment, the grounding electrode used for the service or feeder equipment shall be permitted as the grounding electrode for the separately derived system.

FPN: See 2.50.5.15(d) for bonding requirements of interior metal water piping in the area served by separately derived systems.

(8) Grounded Conductor. Where a grounded conductor is installed and the system bonding jumper is not located at the source of the separately derived system, 2.50.2.11(a)(8)a, (a)(8)b, and (a)(8)c shall apply.

- a. Routing and Sizing. This conductor shall be routed with the derived phase conductors and shall not be smaller than the required grounding electrode conductor specified in Table 2.50.3.17 but shall not be required to be larger than the largest ungrounded derived phase conductor. In addition, for phase conductors larger than 1100 kcmil copper or 850 mm2 aluminum, the grounded conductor shall not be smaller than 12½ percent of the area of the largest derived phase conductor. The grounded conductor of a 3-phase, 3-wire delta system shall have an ampacity not less than that of the ungrounded conductors.

- b. Parallel Conductors. Where the derived phase conductors are installed in parallel, the size of the grounded conductor shall be based on the total circular mil area of the parallel conductors, as indicated in this section. Where installed in two or more raceways, the size of the grounded conductor in each raceway shall be based on the size of the ungrounded conductors in the raceway but not smaller than 50 mm2 .

FPN: See 3.10.1.4 for grounded conductors connected in parallel.

- c. Impedance Grounded System. The grounded conductor of an impedance grounded neutral system shall be installed in accordance with 2.50.2.17 or 2.50.10.7.

(b) Ungrounded Systems. The equipment of an ungrounded separately derived system shall be grounded as specified in 2.50.2.11(b)(1) and (b)(2).

- (1) Grounding Electrode Conductor. A grounding electrode conductor, sized in accordance with 2.50.3.17 for the derived phase conductors, shall be used to connect the metal enclosures of the derived system to the grounding electrode as specified in 2.50.2.11(b)(2). This connection shall be made at any point on the separately derived system from the source to the first system disconnecting means.

- (2) Grounding Electrode. Except as permitted by 2.50.2.15 for portable and vehicle-mounted generators, the grounding electrode shall comply with 2.50.2.11(a)(7).

2.50.2.13 Buildings or Structures Supplied by Feeder(s) or Branch Circuit(s).

(a) Grounding Electrode. Building(s) or structure(s) supplied by feeder(s) or branch circuit(s) shall have a grounding electrode or grounding electrode system installed in accordance with 2.50.3.1. The grounding electrode conductor(s) shall be connected in accordance with 2.50.2.13(b) or (c). Where there is no existing grounding electrode, the grounding electrode(s) required in 2.50.3.1 shall be installed.

Exception: A grounding electrode shall not be required where only a single branch circuit supplies the building or structure and the branch circuit includes an equipment grounding conductor for grounding the conductive non–current-carrying parts of equipment. For the purpose of this section, a multiwire branch circuit shall be considered as a single branch circuit.

(b) Grounded Systems. For a grounded system at the separate building or structure, the connection to the grounding electrode and grounding or bonding of equipment, structures, or frames required to be grounded or bonded shall comply with either 2.50.2.13(b)(1) or (b)(2).

- (1) Equipment Grounding Conductor. An equipment grounding conductor as described in 2.50.6.9 shall be run with the supply conductors and connected to the building or structure disconnecting means and to the grounding electrode(s). The equipment grounding conductor shall be used for grounding or bonding of equipment, structures, or frames required to be grounded or bonded. The equipment grounding conductor shall be sized in accordance with 2.50.6.13. Any installed grounded conductor shall not be connected to the equipment grounding conductor or to the grounding electrode(s).

- (2) Grounded Conductor. Where (1) an equipment grounding conductor is not run with the supply to the building or structure, (2) there are no continuous metallic paths bonded to the grounding system in each building or structure involved, and (3) ground-fault protection of equipment has not been installed on the supply side of the feeder(s), the grounded conductor run with the supply to the building or structure shall be connected to the building or structure disconnecting means and to the grounding electrode(s) and shall be used for grounding or bonding of equipment, structures, or frames required to be grounded or bonded. The size of the grounded conductor shall not be smaller than the larger of either of the following:

- a. That required by 2.20.3.22

- b. That required by 2.50.6.13

(c) Ungrounded Systems. The grounding electrode(s) shall be connected to the building or structure disconnecting means.

(d) Disconnecting Means Located in Separate Building or Structure on the Same Premises. Where one or more disconnecting means supply one or more additional buildings or structures under single management, and where these disconnecting means are located remote from those buildings or structures in accordance with the provisions of 2.25.2.3, Exception Nos. 1 and 2, all of the following conditions shall be met:

- (1) The connection of the grounded conductor to the grounding electrode at a separate building or structure shall not be made.

- (2) An equipment grounding conductor for grounding any non– current-carrying equipment, interior metal piping systems, and building or structural metal frames is run with the circuit conductors to a separate building or structure and bonded to existing grounding electrode(s) required in Part 2.50.3, or, where there are no existing electrodes, the grounding electrode(s) required in Part 2.50.3 shall be installed where a separate building or structure is supplied by more than one branch circuit.

- (3) Bonding the equipment grounding conductor to the grounding electrode at a separate building or structure shall be made in a junction box, panelboard, or similar enclosure located immediately inside or outside the separate building or structure.

- (e) Grounding Electrode Conductor. The size of the grounding electrode conductor to the grounding electrode(s) shall not be smaller than given in 2.50.3.17, based on the largest ungrounded supply conductor. The installation shall comply with Part 2.50.3.

2.50.2.15 Portable and Vehicle-Mounted Generators.

(a) Portable Generators. The frame of a portable generator shall not be required to be connected to a grounding electrode as defined in 2.50.3.3 for a system supplied by the generator under the following conditions:

- (1) The generator supplies only equipment mounted on the generator, cord-and-plug-connected equipment through receptacles mounted on the generator, or both, and

- (2) The non–current-carrying metal parts of equipment and the equipment grounding conductor terminals of the receptacles are bonded to the generator frame.

(b) Vehicle-Mounted Generators. The frame of a vehicle shall not be required to be connected to a grounding electrode as defined in 2.50.3.3 for a system supplied by a generator located on this vehicle under the following conditions:

- (1) The frame of the generator is bonded to the vehicle frame, and

- (2) The generator supplies only equipment located on the vehicle or cord-and-plug-connected equipment through receptacles mounted on the vehicle, or both equipment located on the vehicle and cord-and- plug-connected equipment through receptacles mounted on the vehicle or on the generator, and

- (3) The non–current-carrying metal parts of equipment and the equipment grounding conductor terminals of the receptacles are bonded to the generator frame.

(c) Grounded Conductor Bonding. A system conductor that is required to be grounded by 2.50.2.7 shall be bonded to the generator frame where the generator is a component of a separately derived system.

FPN: For grounding portable generators supplying fixed wiring systems, see 2.50.2.1(d).

2.50.2.17 High-Impedance Grounded Neutral Systems.

High- impedance grounded neutral systems in which a grounding impedance, usually a resistor, limits the ground-fault current to a low value shall be permitted for 3-phase ac systems of 250 volts to 1000 volts where all the following conditions are met:

(1) The conditions of maintenance and supervision ensure that only licensed electrical practitioner or non licensed electrical practitioner under the supervision of a licensed electrical practitioner service the installation.

(2) Continuity of power is required.

(3) Ground detectors are installed on the system.

(4) Line-to-neutral loads are not served.

High-impedance grounded neutral systems shall comply with the provisions of 2.50.2.17(a) through (g).

(a) Grounding Impedance Location. The grounding impedance shall be installed between the grounding electrode conductor and the system neutral. Where a neutral is not available, the grounding impedance shall be installed between the grounding electrode conductor and the neutral derived from a grounding transformer.

(b) Neutral Conductor. The neutral conductor from the neutral point of the transformer or generator to its connection point to the grounding impedance shall be fully insulated.

The neutral conductor shall have an ampacity of not less than the maximum current rating of the grounding impedance. In no case shall the neutral conductor be smaller than 8.0 mm2 (3.2 mm dia.) copper or 14 mm2 aluminum or copper-clad aluminum. (c) System Neutral Connection. The system neutral conductor shall not be connected to ground except through the grounding impedance.

FPN: The impedance is normally selected to limit the ground-fault current to a value slightly greater than or equal to the capacitive charging current of the system. This value of impedance will also limit transient overvoltages to safe values. For guidance, refer to criteria for limiting transient overvoltages in ANSI/IEEE 142-1991, Recommended Practice for Grounding of Industrial and Commercial Power Systems.

(d) Neutral Conductor Routing. The conductor connecting the neutral point of the transformer or generator to the grounding impedance shall be permitted to be installed in a separate raceway. It shall not be required to run this conductor with the phase conductors to the first system disconnecting means or overcurrent device.

(e) Equipment Bonding Jumper. The equipment bonding jumper (the connection between the equipment grounding conductors and the grounding impedance) shall be an unspliced conductor run from the first system disconnecting means or overcurrent device to the grounded side of the grounding impedance.

(f) Grounding Electrode Conductor Location. The grounding electrode conductor shall be attached at any point from the grounded side of the grounding impedance to the equipment grounding connection at the service equipment or first system disconnecting means.

(g) Equipment Bonding Jumper Size. The equipment bonding jumper shall be sized in accordance with (1) or (2) as follows:

- (1) Where the grounding electrode conductor connection is made at the grounding impedance, the equipment bonding jumper shall be sized in accordance with 2.50.3.17, based on the size of the service entrance conductors for a service or the derived phase conductors for a separately derived system.

- (2) Where the grounding electrode conductor is connected at the first system disconnecting means or overcurrent device, the equipment bonding jumper shall be sized the same as the neutral conductor in 2.50.2.17(b).

2.50.3 Grounding Electrode System and Grounding Electrode Conductor

2.50.3.1 Grounding Electrode System.

All grounding electrodes as described in 2.50.3.3(a)(1) through (a)(6) that are present at each building or structure served shall be bonded together to form the grounding electrode system. Where none of these grounding electrodes exist, one or more of the grounding electrodes specified in 2.50.3.3(a)(4) through (a)(7) shall be installed and used.

Exception: Concrete-encased electrodes of existing buildings or structures shall not be required to be part of the grounding electrode system where the steel reinforcing bars or rods are not accessible for use without disturbing the concrete.

2.50.3.3 Grounding Electrodes.

(a) Electrodes Permitted for Grounding.

- (1) Metal Underground Water Pipe. A metal underground water pipe in direct contact with the earth for 3 000 mm or more (including any metal well casing effectively bonded to the pipe) and electrically continuous (or made electrically continuous by bonding around insulating joints or insulating pipe) to the points of connection of the grounding electrode conductor and the bonding conductors. Interior metal water piping located more than 1 500 mm from the point of entrance to the building shall not be used as a part of the grounding electrode system or as a conductor to interconnect electrodes that are part of the grounding electrode system.

Exception: In industrial and commercial buildings or structures where conditions of maintenance and supervision ensure that only licensed electrical practitioner or non licensed electrical practitioner under the supervision of a licensed electrical practitioner service the installation, interior metal water piping located more than 1 500 mm from the point of entrance to the building shall be permitted as a part of the grounding electrode system or as a conductor to interconnect electrodes that are part of the grounding electrode system, provided that the entire length, other than short sections passing perpendicular through walls, floors, or ceilings, of the interior metal water pipe that is being used for the conductor is exposed.

- (2) Metal Frame of the Building or Structure. The metal frame of the building or structure, where any of the following methods are used to make an earth connection:

- a. 3 000 mm or more of a single structural metal member in direct contact with the earth or encased in concrete that is in direct contact with the earth

- b. The structural metal frame is bonded to one or more of the grounding electrodes as defined in 2.50.3.3(a)(1), (a)(3), or (a)(4)

- c. The structural metal frame is bonded to one or more of the grounding electrodes as defined in 2.50.3.3(a)(5) or (a)(6) that comply with 2.50.3.7, or

- d. Other approved means of establishing a connection to earth.

- (3) Concrete-Encased Electrode. An electrode encased by at least 50 mm of concrete, located within and near the bottom of a concrete foundation or footing that is in direct contact with the earth, consisting of at least 6 000 mm of one or more bare or zinc galvanized or other electrically conductive coated steel reinforcing bars or rods of not less than 13 mm in diameter, or consisting of at least 6 000 mm of bare copper conductor not smaller than 22 mm2 . Reinforcing bars shall be permitted to be bonded together by the usual steel tie wires or other effective means.

- (4) Ground Ring. A ground ring encircling the building or structure, in direct contact with the earth, consisting of at least 6 000 mm of bare copper conductor not smaller than 30 mm2 . (5) Rod and Pipe Electrodes. Rod and pipe electrodes shall not be less than 2 400 mm in length and shall consist of the following materials.

- a. Electrodes of pipe or conduit shall not be smaller than metric designator 21 (trade size ¾) and, where of iron or steel, shall have the outer surface galvanized or otherwise metal-coated for corrosion protection.

- b. Electrodes of rods of iron or steel shall be at least 16 mm in diameter. Stainless steel rods less than 16 mm in diameter, nonferrous rods, or their equivalent shall be listed and shall not be less than 13 mm in diameter.

- (6) Plate Electrodes. Each plate electrode shall expose not less than 0.186 m 2 (2 ft 2 ) of surface to exterior soil. Electrodes of iron or steel plates shall be at least 6 mm in thickness. Electrodes of nonferrous metal shall be at least 1.5 mm in thickness.

- (7) Other Local Metal Underground Systems or Structures. Other local metal underground systems or structures such as piping systems, underground tanks, and underground metal well casings that are not effectively bonded to a metal water pipe.

(b) Electrodes Not Permitted for Grounding. The following shall not be used as grounding electrodes:

- (1) Metal underground gas piping system

- (2) Aluminum electrodes

FPN: See 2.50.5.15(b) for bonding requirements of gas piping.

2.50.3.4 Grounding Electrode System Installation.

FPN: See 5.47.1.9 and 5.47.1.10 for special grounding and bonding requirements for agricultural buildings.

(a) Rod, Pipe, and Plate Electrodes. Where practicable, rod, pipe, and plate electrodes shall be embedded below permanent moisture level. Rod, pipe, and plate electrodes shall be free from nonconductive coatings such as paint or enamel.

(b) Electrode Spacing. Where more than one of the electrodes of the type specified in 2.50.3.3(a)(5) or (a)(6) are used, each electrode of one grounding system (including that used for air terminals) shall not be less than 1 800 mm from any other electrode of another grounding system. Two or more grounding electrodes that are effectively bonded together shall be considered a single grounding electrode system.

(c) Bonding Jumper. The bonding jumper(s) used to connect the grounding electrodes together to form the grounding electrode system shall be installed in accordance with 2.50.3.15(a), (b), and (e), shall be sized in accordance with 2.50.3.17, and shall be connected in the manner specified in 2.50.3.21.

(d) Metal Underground Water Pipe. Where used as a grounding electrode, metal underground water pipe shall meet the requirements of 2.50.3.4(d)(1) and (d)(2).

- (1) Continuity. Continuity of the grounding path or the bonding connection to interior piping shall not rely on water meters or filtering devices and similar equipment.

- (2) Supplemental Electrode Required. A metal underground water pipe shall be supplemented by an additional electrode of a type specified in 2.50.3.3(a)(2) through (a)(7). Where the supplemental electrode is a rod, pipe, or plate type, it shall comply with 2.50.3.7. The supplemental electrode shall be permitted to be bonded to the grounding electrode conductor, the grounded service-entrance conductor, the nonflexible grounded service raceway, or any grounded service enclosure.

Exception: The supplemental electrode shall be permitted to be bonded to the interior metal water piping at any convenient point as covered in 2.50.3.3(a)(1), Exception.

(e) Supplemental Electrode Bonding Connection Size. Where the supplemental electrode is a rod, pipe, or plate electrode, that portion of the bonding jumper that is the sole connection to the supplemental grounding electrode shall not be required to be larger than 14 mm2 copper wire or 22 mm2 aluminum wire.

(f) Ground Ring. The ground ring shall be buried at a depth below the earth’s surface of not less than 750 mm.

(g) Rod and Pipe Electrodes. The electrode shall be installed such that at least 2 400 mm of length is in contact with the soil. It shall be driven to a depth of not less than 2 400 mm except that, where rock bottom is encountered, the electrode shall be driven at an oblique angle not to exceed 45 degrees from the vertical or, where rock bottom is encountered at an angle up to 45 degrees, the electrode shall be permitted to be buried in a trench that is at least 750 mm deep. The upper end of the electrode shall be flush with or below ground level unless the aboveground end and the grounding electrode conductor attachment are protected against physical damage as specified in 2.50.1.10.

(h) Plate Electrode. Plate electrodes shall be installed not less than 750 mm below the surface of the earth.

2.50.3.5 Supplementary Grounding Electrodes.

Supplementary grounding electrodes shall be permitted to be connected to the equipment grounding conductors specified in 2.50.6.9 and shall not be required to comply with the electrode bonding requirements of 2.50.3.1 or 2.50.3.4(c) or the resistance requirements of 2.50.3.7, but the earth shall not be used as an effective ground-fault current path as specified in 2.50.1.4(a)(5) and 2.50.1.4(b)(4).

2.50.3.7 Resistance of Rod, Pipe, and Plate Electrodes.

A single electrode consisting of a rod, pipe, or plate that does not have a resistance to ground of 25 ohms or less shall be augmented by one additional electrode of any of the types specified by 2.50.3.3(a)(2) through (a)(7). Where multiple rod, pipe, or plate electrodes are installed to meet the requirements of this section, they shall not be less than 1 800 mm apart.

FPN: The paralleling efficiency of rods longer than 2 400 mm is improved by spacing greater than 1 800 mm.

2.50.3.9 Common Grounding Electrode.

Where an ac system is connected to a grounding electrode in or at a building or structure, the same electrode shall be used to ground conductor enclosures and equipment in or on that building or structure. Where separate services, feeders, or branch circuits supply a building and are required to be connected to a grounding electrode(s), the same grounding electrode(s) shall be used.

Two or more grounding electrodes that are effectively bonded together shall be considered as a single grounding electrode system in this sense.

2.50.3.11 Use of Air Terminals.

Air terminal conductors and driven pipes, rods, or plate electrodes used for grounding air terminals shall not be used in lieu of the grounding electrodes required by 2.50.3.1 for grounding wiring systems and equipment. This provision shall not prohibit the required bonding together of grounding electrodes of different systems.

FPN No. 1: See 2.50.5.17 for spacing from air terminals. See 8.0.4.1(d), 8.10.2.11(j), and 8.20.4.1(d) for bonding of electrodes.

FPN No. 2: Bonding together of all separate grounding electrodes will limit potential differences between them and between their associated wiring systems. 2.50.3.13 Grounding Electrode Conductor Material. The grounding electrode conductor shall be of copper, aluminum, or copper-clad aluminum. The material selected shall be resistant to any corrosive condition existing at the installation or shall be suitably protected against corrosion. The conductor shall be solid or stranded, insulated, covered, or bare.

2.50.3.15 Grounding Electrode Conductor Installation.

Grounding electrode conductors shall be installed as specified in 2.50.3.15(a) through (f).

(a) Aluminum or Copper-Clad Aluminum Conductors. Bare aluminum or copper-clad aluminum grounding conductors shall not be used where in direct contact with masonry or the earth or where subject to corrosive conditions. Where used outside, aluminum or copper-clad aluminum grounding conductors shall not be terminated within 450 mm of the earth.

(b) Securing and Protection Against Physical Damage. Where exposed, a grounding electrode conductor or its enclosure shall be securely fastened to the surface on which it is carried. A 22 mm2 or larger copper or aluminum grounding electrode conductor shall be protected where exposed to physical damage. A 14 mm2 grounding electrode conductor that is free from exposure to physical damage shall be permitted to be run along the surface of the building construction without metal covering or protection where it is securely fastened to the construction; otherwise, it shall be in rigid metal conduit, intermediate metal conduit, rigid nonmetallic conduit, electrical metallic tubing, or cable armor. Grounding electrode conductors smaller than 14 mm2 shall be in rigid metal conduit, intermediate metal conduit, rigid nonmetallic conduit, electrical metallic tubing, or cable armor.

(c) Continuous. Grounding electrode conductor(s) shall be installed in one continuous length without a splice or joint except as permitted in (1) through (4):

- (1) Splicing shall be permitted only by irreversible compression- type connectors listed as grounding and bonding equipment or by the exothermic welding process.

- (2) Sections of busbars shall be permitted to be connected together to form a grounding electrode conductor.

- (3) Bonding jumper(s) from grounding electrode(s) and grounding electrode conductor(s) shall be permitted to be connected to an aluminum or copper busbar not less than 6 mm × 50 mm. The busbar shall be securely fastened and shall be installed in an accessible location. Connections shall be made by a listed connector or by the exothermic welding process.

- (4) Where aluminum busbars are used, the installation shall comply with 2.50.3.15(a).

(d) Grounding Electrode Conductor Taps. Where a service consists of more than a single enclosure as permitted in 2.30.6.2(a), it shall be permitted to connect taps to the common grounding electrode conductor. Each such tap conductor shall extend to the inside of each such enclosure. The common grounding electrode conductor shall be sized in accordance with 2.50.3.17, based on the sum of the circular mil area of the largest ungrounded service entrance conductors. Where more than one set of service entrance conductors as permitted by 2.30.4.1, Exception No. 2 connect directly to a service drop or lateral, the common grounding electrode conductor shall be sized in accordance with Table 2.50.3.17 Note 1. The tap conductors shall be permitted to be sized in accordance with the grounding electrode conductors specified in 2.50.3.17 for the largest conductor serving the respective enclosures. The tap conductors shall be connected to the common grounding electrode conductor in such a manner that the common grounding electrode conductor remains without a splice or joint.

(e) Enclosures for Grounding Electrode Conductors. Ferrous metal enclosures for grounding electrode conductors shall be electrically continuous from the point of attachment to cabinets or equipment to the grounding electrode and shall be securely fastened to the ground clamp or fitting. Nonferrous metal enclosures shall not be required to be electrically continuous. Ferrous metal enclosures that are not physically continuous from cabinets or equipment to the grounding electrode shall be made electrically continuous by bonding each end of the raceway or enclosure to the grounding electrode conductor. Bonding shall apply at each end and to all intervening ferrous raceways, boxes, and enclosures between the service equipment and the grounding electrode. The bonding jumper for a grounding electrode conductor raceway or cable armor shall be the same size as, or larger than, the required enclosed grounding electrode conductor. Where a raceway is used as protection for a grounding electrode conductor, the installation shall comply with the requirements of the appropriate raceway article.

(f) To Electrode(s). A grounding electrode conductor shall be permitted to be run to any convenient grounding electrode available in the grounding electrode system, or to one or more grounding electrode(s) individually, or to the aluminum or copper busbar as permitted in 2.50.3.15(c). The grounding electrode conductor shall be sized for the largest grounding electrode conductor required among all the electrodes connected to it.

2.50.3.17 Size of Alternating-Current Grounding Electrode Conductor.

The size of the grounding electrode conductor of a grounded or ungrounded ac system shall not be less than given in Table 2.50.3.17, except as permitted in 2.50.3.17(a) through (c).

FPN: See 2.50.2.5(c) for size of ac system conductor brought to service equipment.

(a) Connections to Rod, Pipe, or Plate Electrodes. Where the grounding electrode conductor is connected to rod, pipe, or plate electrodes as permitted in 2.50.3.3(a)(5) or (a)(6), that portion of the conductor that is the sole connection to the grounding electrode shall not be required to be larger than 14 mm2 copper wire or 22 mm2 aluminum wire.

(b) Connections to Concrete-Encased Electrodes. Where the grounding electrode conductor is connected to a concrete-encased electrode as permitted in 2.50.3.3(a)(3), that portion of the conductor that is the sole connection to the grounding electrode shall not be required to be larger than 22 mm2 copper wire.

(c) Connections to Ground Rings. Where the grounding electrode conductor is connected to a ground ring as permitted in 2.50.3.3(a)(4), that portion of the conductor that is the sole connection to the grounding electrode shall not be required to be larger than the conductor used for the ground ring.

| Size of Largest Ungrounded Service- Entrance Conductor or Equivalent Area for Parallel Conductorsa mm2 | Size of Grounding Electrode Conductor mm2 (mm dia) | ||

|---|---|---|---|

| Copper | Aluminum or Copper-Clad Aluminum | Copper | Aluminum or Copper-Clad Aluminum b |

| 30 or smaller | 50 or smaller | 8.0(3.2) | 14 |

| 38 or 50 | 60 or 80 | 14 | 22 |

| 60 or 80 | 100 or 125 | 22 | 30 |

| Over 80 through 175 | Over 125 through 250 | 30 | 50 |

| Over 175 through 600 | Over 250 through 900 | 50 | 80 |

| Over 600 through 1100 | Over 900 through 1750 | 60 | 100 |

| Over 1100 | Over 1750 | 80 | 125 |

Notes:

| |||

2.50.3.19 Grounding Electrode Conductor and Bonding Jumper Connection to Grounding Electrodes.

(a) Accessibility. The connection of a grounding electrode conductor or bonding jumper to a grounding electrode shall be accessible.

Exception No. 1: An encased or buried connection to a concrete- encased, driven, or buried grounding electrode shall not be required to be accessible.

Exception No. 2: An exothermic or irreversible compression connection to fire-proofed structural metal shall not be required to be accessible.

(b) Effective Grounding Path. The connection of a grounding electrode conductor or bonding jumper to a grounding electrode shall be made in a manner that will ensure a permanent and effective grounding path. Where necessary to ensure the grounding path for a metal piping system used as a grounding electrode, effective bonding shall be provided around insulated joints and around any equipment likely to be disconnected for repairs or replacement. Bonding conductors shall be of sufficient length to permit removal of such equipment while retaining the integrity of the bond.

2.50.3.21 Methods of Grounding and Bonding Conductor Connection to Electrodes.

The grounding or bonding conductor shall be connected to the grounding electrode by exothermic welding, listed lugs, listed pressure connectors, listed clamps, or other listed means. Connections depending on solder shall not be used. Ground clamps shall be listed for the materials of the grounding electrode and the grounding electrode conductor and, where used on pipe, rod, or other buried electrodes, shall also be listed for direct soil burial or concrete encasement. Not more than one conductor shall be connected to the grounding electrode by a single clamp or fitting unless the clamp or fitting is listed for multiple conductors. One of the following methods shall be used:

(1) A pipe fitting, pipe plug, or other approved device screwed into a pipe or pipe fitting

(2) A listed bolted clamp of cast bronze or brass, or plain or malleable iron

(3) For indoor telecommunications purposes only, a listed sheet metal strap-type ground clamp having a rigid metal base that seats on the electrode and having a strap of such material and dimensions that it is not likely to stretch during or after installation

(4) An equally substantial approved means

2.50.4 Enclosure, Raceway, and Service Cable Grounding

2.50.4.1 Service Raceways and Enclosures.

Metal enclosures and raceways for service conductors and equipment shall be grounded. Exception: A metal elbow that is installed in an underground installation of rigid nonmetallic conduit and is isolated from possible contact by a minimum cover of 450 mm to any part of the elbow shall not be required to be grounded.

2.50.4.5 Underground Service Cable or Raceway.

(a) Underground Service Cable. The sheath or armor of a continuous underground metal-sheathed or armored service cable system that is bonded to the grounded underground system shall not be required to be grounded at the building or structure. The sheath or armor shall be permitted to be insulated from the interior metal raceway conduit or piping.

(b) Underground Service Raceway Containing Cable. An underground metal service raceway that contains a metal-sheathed or armored cable bonded to the grounded underground system shall not be required to be grounded at the building or structure. The sheath or armor shall be permitted to be insulated from the interior metal raceway or piping.

2.50.4.7 Other Conductor Enclosures and Raceways.

Except as permitted by 2.50.6.3(i), metal enclosures and raceways for other than service conductors shall be grounded.

Exception No. 1: Metal enclosures and raceways for conductors added to existing installations of open wire, knob and tube wiring, and nonmetallic-sheathed cable shall not be required to be grounded where these enclosures or wiring methods comply with (1) through (4) as follows:

- (1) Do not provide an equipment ground

- (2) Are in runs of less than 7 600 mm

- (3) Are free from probable contact with ground, grounded metal, metal lath, or other conductive material

- (4) Are guarded against contact by persons

Exception No. 2: Short sections of metal enclosures or raceways used to provide support or protection of cable assemblies from physical damage shall not be required to be grounded.

Exception No. 3: A metal elbow shall not be required to be grounded where it is installed in a nonmetallic raceway and is isolated from possible contact by a minimum cover of 450 mm to any part of the elbow or is encased in not less than 50 mm of concrete.

2.50.5 Bonding

2.50.5.1 General.

Bonding shall be provided where necessary to ensure electrical continuity and the capacity to conduct safely any fault current likely to be imposed.

2.50.5.3 Services.

(a) Bonding of Services. The non–current-carrying metal parts of equipment indicated in 2.50.5.3(a)(1), (a)(2), and (a)(3) shall be effectively bonded together.

- (1) The service raceways, cable trays, cablebus framework, auxiliary gutters, or service cable armor or sheath except as permitted in 2.50.4.5.

- (2) All service enclosures containing service conductors, including meter fittings, boxes, or the like, interposed in the service raceway or armor.

- (3) Any metallic raceway or armor enclosing a grounding electrode conductor as specified in 2.50.3.15(b). Bonding shall apply at each end and to all intervening raceways, boxes, and enclosures between the service equipment and the grounding electrode.

(b) Method of Bonding at the Service. Electrical continuity at service equipment, service raceways, and service conductor enclosures shall be ensured by one of the following methods:

- (1) Bonding equipment to the grounded service conductor in a manner provided in 2.50.1.8

- (2) Connections utilizing threaded couplings or threaded bosses on enclosures where made up wrenchtight

- (3) Threadless couplings and connectors where made up tight for metal raceways and metal-clad cables

- (4) Other listed devices, such as bonding-type locknuts, bushings, or bushings with bonding jumpers

Bonding jumpers meeting the other requirements of this article shall be used around concentric or eccentric knockouts that are punched or otherwise formed so as to impair the electrical connection to ground. Standard locknuts or bushings shall not be the sole means for the bonding required by this section.

2.50.5.5 Bonding for Other Systems.

An accessible means external to enclosures for connecting intersystem bonding and grounding electrode conductors shall be provided at the service equipment and at the disconnecting means for any additional buildings or structures by at least one of the following means:

(1) Exposed nonflexible metallic raceways

(2) Exposed grounding electrode conductor

(3) Approved means for the external connection of a copper or other corrosion-resistant bonding or grounding conductor to the grounded raceway or equipment

FPN No. 1: A 14 mm2 copper conductor with one end bonded to the grounded nonflexible metallic raceway or equipment and with 150 mm or more of the other end made accessible on the outside wall is an example of the approved means covered in 2.50.5.5(3).

FPN No. 2: See 8.0.4.1, 8.10.2.11, and 8.20.4.1 for bonding and grounding requirements for communications circuits, radio and television equipment, and CATV circuits.

2.50.5.7 Bonding Other Enclosures.

(a) General. Metal raceways, cable trays, cable armor, cable sheath, enclosures, frames, fittings, and other metal non–current-carrying parts that are to serve as grounding conductors, with or without the use of supplementary equipment grounding conductors, shall be effectively bonded where necessary to ensure electrical continuity and the capacity to conduct safely any fault current likely to be imposed on them. Any nonconductive paint, enamel, or similar coating shall be removed at threads, contact points, and contact surfaces or be connected by means of fittings designed so as to make such removal unnecessary.

(b) Isolated Grounding Circuits. Where required for the reduction of electrical noise (electromagnetic interference) on the grounding circuit, an equipment enclosure supplied by a branch circuit shall be permitted to be isolated from a raceway containing circuits supplying only that equipment by one or more listed nonmetallic raceway fittings located at the point of attachment of the raceway to the equipment enclosure. The metal raceway shall comply with provisions of this article and shall be supplemented by an internal insulated equipment grounding conductor installed in accordance with 2.50.7.17(d) to ground the equipment enclosure.

FPN: Use of an isolated equipment grounding conductor does not relieve the requirement for grounding the raceway system.

2.50.5.8 Bonding for Over 250 Volts.

For circuits of over 250 volts to ground, the electrical continuity of metal raceways and cables with metal sheaths that contain any conductor other than service conductors shall be ensured by one or more of the methods specified for services in 2.50.5.3(b), except for (b)(1).

Exception: Where oversized, concentric, or eccentric knockouts are not encountered, or where a box or enclosure with concentric or eccentric knockouts listed to provide a permanent, reliable electrical bond, the following methods shall be permitted:

(1) Threadless couplings and connectors for cables with metal sheaths

(2) Two locknuts, on rigid metal conduit or intermediate metal conduit, one inside and one outside of boxes and cabinets

(3) Fittings with shoulders that seat firmly against the box or cabinet, such as electrical metallic tubing connectors, flexible metal conduit connectors, and cable connectors, with one locknut on the inside of boxes and cabinets

(4) Listed fittings

2.50.5.9 Bonding Loosely Jointed Metal Raceways.

Expansion fittings and telescoping sections of metal raceways shall be made electrically continuous by equipment bonding jumpers or other means.

2.50.5.11 Bonding in Hazardous (Classified) Locations.

Regardless of the voltage of the electrical system, the electrical continuity of non– current-carrying metal parts of equipment, raceways, and other enclosures in any hazardous (classified) location as defined in Article 500 shall be ensured by any of the methods specified in 2.50.5.3(b)(2) through (b)(4) that are approved for the wiring method used. One or more of these bonding methods shall be used whether or not supplementary equipment grounding conductors are installed.

2.50.5.13 Equipment Bonding Jumpers.

(a) Material. Equipment bonding jumpers shall be of copper or other corrosion-resistant material. A bonding jumper shall be a wire, bus, screw, or similar suitable conductor.

(b) Attachment. Equipment bonding jumpers shall be attached in the manner specified by the applicable provisions of 2.50.1.8 for circuits and equipment and by 2.50.3.21 for grounding electrodes.

(c) Size — Equipment Bonding Jumper on Supply Side of Service. The bonding jumper shall not be smaller than the sizes shown in Table 2.50.3.17 for grounding electrode conductors. Where the service-entrance phase conductors are larger than 1100 kcmil copper or 850 mm2 aluminum, the bonding jumper shall have an area not less than 12½ percent of the area of the largest phase conductor except that, where the phase conductors and the bonding jumper are of different materials (copper or aluminum), the minimum size of the bonding jumper shall be based on the assumed use of phase conductors of the same material as the bonding jumper and with an ampacity equivalent to that of the installed phase conductors. Where the service-entrance conductors are paralleled in two or more raceways or cables, the equipment bonding jumper, where routed with the raceways or cables, shall be run in parallel. The size of the bonding jumper for each raceway or cable shall be based on the size of the service-entrance conductors in each raceway or cable.

(d) Size — Equipment Bonding Jumper on Load Side of Service. The equipment bonding jumper on the load side of the service overcurrent devices shall be sized, as a minimum, in accordance with the sizes listed in Table 2.50.6.13, but shall not be required to be larger than the largest ungrounded circuit conductors supplying the equipment and shall not be smaller than 2.0 mm2 (1.6 mm dia.). A single common continuous equipment bonding jumper shall be permitted to bond two or more raceways or cables where the bonding jumper is sized in accordance with Table 2.50.6.13 for the largest overcurrent device supplying circuits therein.

(e) Installation. The equipment bonding jumper shall be permitted to be installed inside or outside of a raceway or enclosure. Where installed on the outside, the length of the equipment bonding jumper shall not exceed 1 800 mm and shall be routed with the raceway or enclosure. Where installed inside of a raceway, the equipment bonding jumper shall comply with the requirements of 2.50.6.10 and 2.50.7.19.

Exception: An equipment bonding jumper longer than 1 800 mm shall be permitted at outside pole locations for the purpose of bonding or grounding isolated sections of metal raceways or elbows installed in exposed risers of metal conduit or other metal raceway.

2.50.5.15 Bonding of Piping Systems and Exposed Structural Steel.

(a) Metal Water Piping. The metal water piping system shall be bonded as required in (a)(1), (a)(2), or (a)(3) of this section. The bonding jumper(s) shall be installed in accordance with 2.50.3.15(a), (b), and (e). The points of attachment of the bonding jumper(s) shall be accessible.

- (1) General. Metal water piping system(s) installed in or attached to a building or structure shall be bonded to the service equipment enclosure, the grounded conductor at the service, the grounding electrode conductor where of sufficient size, or to the one or more grounding electrodes used. The bonding jumper(s) shall be sized in accordance with Table 2.50.3.17 except as permitted in 2.50.5.15(a)(2) and (a)(3).

- (2) Buildings of Multiple Occupancy. In buildings of multiple occupancy where the metal water piping system(s) installed in or attached to a building or structure for the individual occupancies is metallically isolated from all other occupancies by use of nonmetallic water piping, the metal water piping system(s) for each occupancy shall be permitted to be bonded to the equipment grounding terminal of the panelboard or switchboard enclosure (other than service equipment) supplying that occupancy. The bonding jumper shall be sized in accordance with Table 2.50.6.13.

- (3) Multiple Buildings or Structures Supplied by a Feeder(s) or Branch Circuit(s). The metal water piping system(s) installed in or attached to a building or structure shall be bonded to the building or structure disconnecting means enclosure where located at the building or structure, to the equipment grounding conductor run with the supply conductors, or to the one or more grounding electrodes used. The bonding jumper(s) shall be sized in accordance with 2.50.3.17, based on the size of the feeder or branch circuit conductors that supply the building. The bonding jumper shall not be required to be larger than the largest ungrounded feeder or branch circuit conductor supplying the building.