Philippine Electrical Code 2017 Part 1/Chapter 2. Wiring and Protection/Article 2.30 - Services

Article 2.30 - Services

While the authors have used good faith and efforts to ensure that the information and instructions contained in this work are accurate, the authors disclaim all responsibility for errors or omissions, including without limitation responsibility for damages resulting from the use of or reliance on this work. Use of the information and instructions contained in this work is at your own risk. If any contents or other technology this work contains or describes is subject to open source licenses or the intellectual property rights of others, it is your responsibility to ensure that your use thereof complies with such licenses and/or rights.

Note: This is a work in progress...

2.30.1 General

2.30.1.1 Scope.

This article covers service conductors and equipment for control and protection of services and their installation requirements.

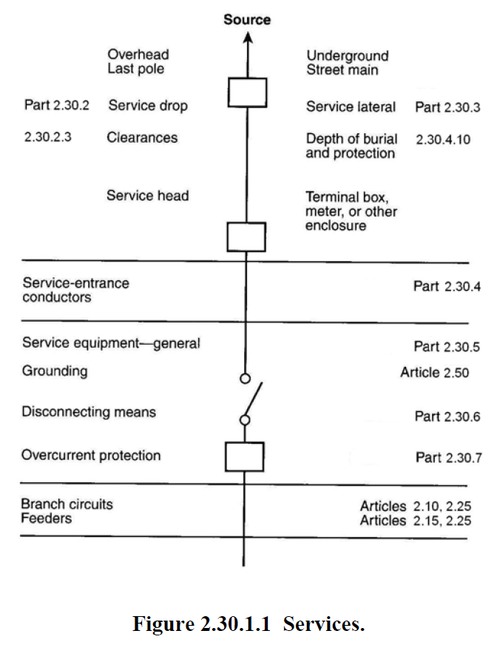

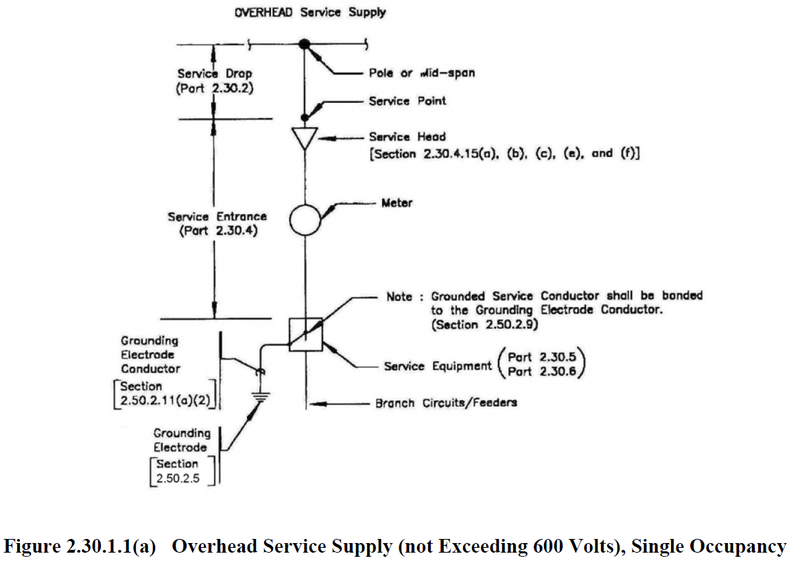

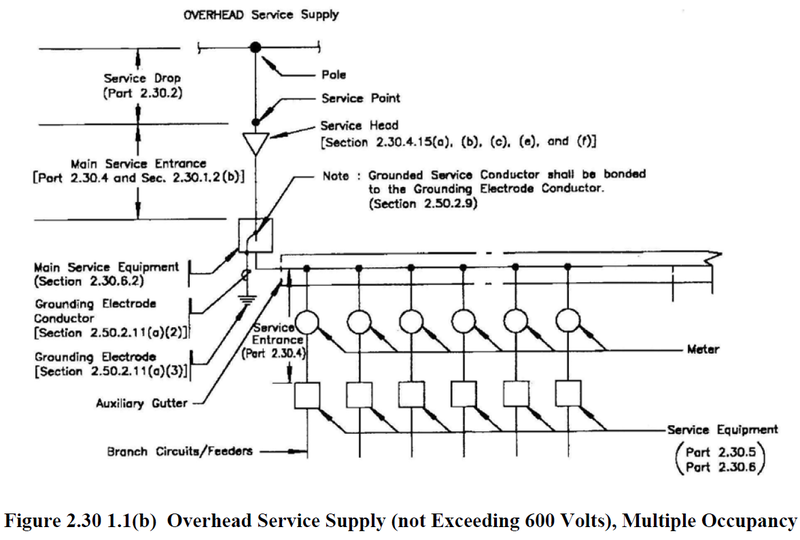

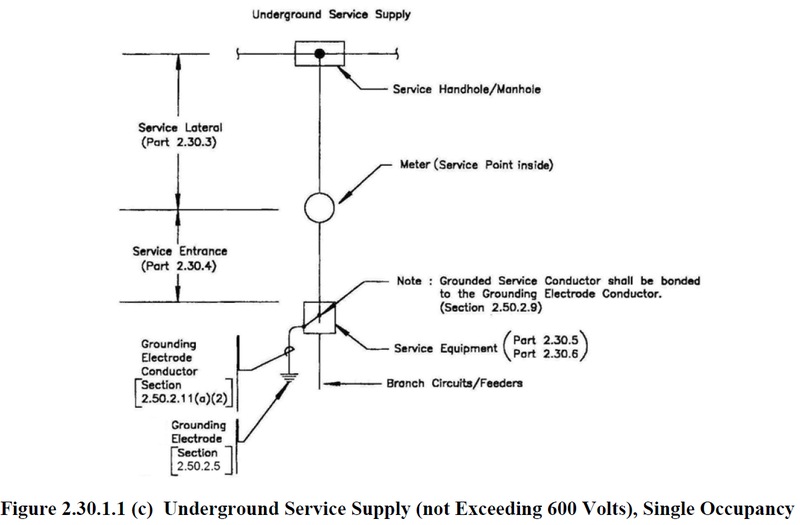

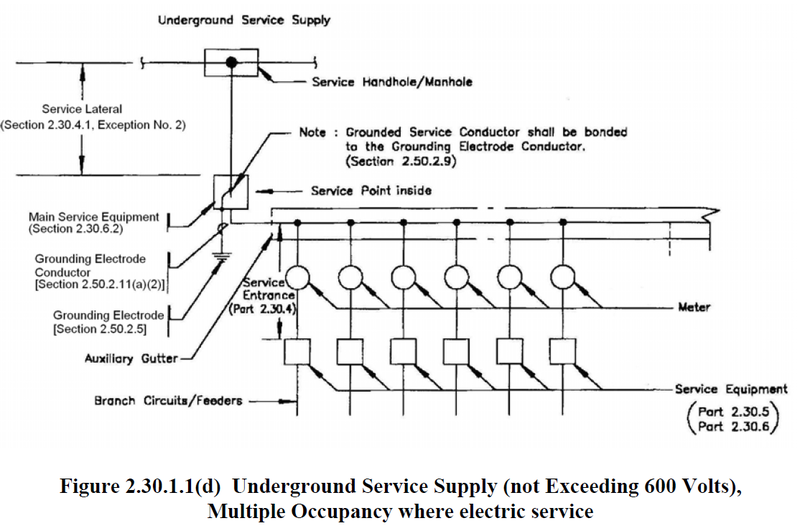

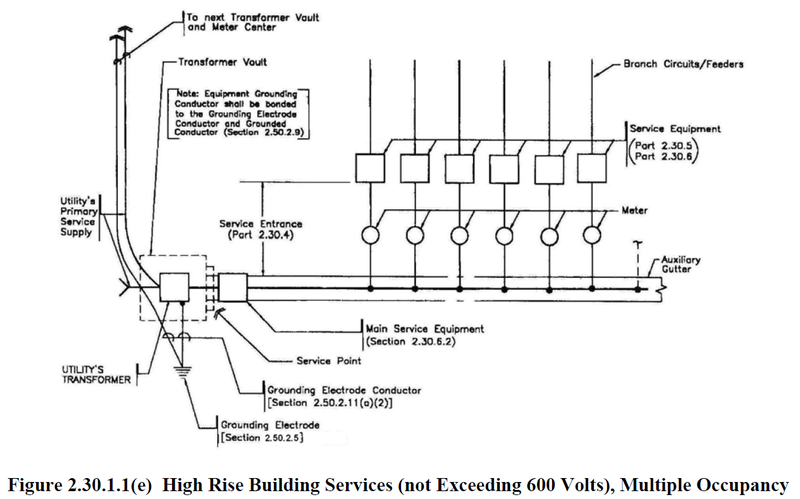

FPN: See Figure 2.30.1.1.

2.30.1.2 Number of Services.

A building or other structure served shall be supplied by only one service unless permitted in 2.30.1.2(a) through (d). For the purpose of 2.30.4.1, Exception No. 2 only, underground sets of conductors, 50 mm2 and larger, running to the same location and connected together at their supply end but not connected together at their load end shall be considered to be supplying one service.

(a) Special Conditions.

Additional services shall be permitted to supply the following:

- (1) Fire pumps

- (2) Emergency systems

- (3) Legally required standby systems

- (4) Optional standby systems

- (5) Parallel power production systems

- (6) Systems designed for connection to multiple sources of supply for the purpose of enhanced reliability

(b) Special Occupancies.

By special permission, additional services shall be permitted for either of the following:

- (1) Multiple-occupancy buildings where there is no available space for service equipment accessible to all occupants

- (2) A single building or other structure sufficiently large to make two or more services necessary

(c) Capacity Requirements.

Additional services shall be permitted under any of the following:

- (1) Where the capacity requirements are in excess of 2000 amperes at a supply voltage of 600 volts or less

- (2) Where the load requirements of a single-phase installation are greater than the serving agency normally supplies through one service

- (3) By special permission

(d) Different Characteristics.

Additional services shall be permitted for different voltages, frequencies, or phases, or for different uses, such as for different rate schedules.

(e) Identification.

Where a building or structure is supplied by more than one service, or any combination of branch circuits, feeders, and services, a permanent plaque or directory shall be installed at each service disconnect location denoting all other services, feeders, and branch circuits supplying that building or structure and the area served by each. See Section 2.25.2.8.

2.30.1.3 One Building or Other Structure Not to Be Supplied Through Another.

Service conductors supplying a building or other structure shall not pass through the interior of another building or other structure.

2.30.1.6 Conductors Considered Outside the Building.

Conductors shall be considered outside of a building or other structure under any of the following conditions:

- (1) Where installed under not less than 50 mm of concrete beneath a building or other structure

- (2) Where installed within a building or other structure in a raceway that is encased in concrete or brick not less than 50 mm thick

- (3) Where installed in any vault that meets the construction requirements of Article 4.50.3.

- (4) Where installed in conduit and under not less than 450 mm of earth beneath a building or other structure

2.30.1.7 Other Conductors in Raceway or Cable.

Conductors other than service conductors shall not be installed in the same service raceway or service cable.

Exception No. 1: Grounding conductors and bonding jumpers.

Exception No. 2: Load management control conductors having overcurrent protection.

2.30.1.8 Raceway Seal.

Where a service raceway enters a building or structure from an underground distribution system, it shall be sealed in accordance with Section 3.0.1.5(g). Spare or unused raceways shall also be sealed. Sealants shall be identified for use with the cable insulation, shield, or other components.

2.30.1.9 Clearances on Buildings.

Service conductors and final spans shall comply with 2.30.1.9(a), (b), and (c).

(a) Clearances.

Service conductors installed as open conductors or multiconductor cable without an overall outer jacket shall have a clearance of not less than 900 mm from windows that are designed to be opened, doors, porches, balconies, ladders, stairs, fire escapes, or similar locations.

Exception: Conductors run above the top level of a window shall be permitted to be less than the 900 mm requirement.

(b) Vertical Clearance.

The vertical clearance of final spans above, or within 900 mm measured horizontally of, platforms, projections, or surfaces from which they might be reached shall be maintained in accordance with 2.30.2.3(b).

(c) Building Openings.

Overhead service conductors shall not be installed beneath openings through which materials may be moved, such as openings in farm and commercial buildings, and shall not be installed where they obstruct entrance to these building openings.

2.30.1.10 Vegetation as Support.

Vegetation such as trees shall not be used for support of overhead service conductors.

2.30.2 Overhead Service-Drop Conductors

2.30.2.1 Insulation or Covering.

Individual conductors shall be insulated or covered.

Exception: The grounded conductor of a multiconductor cable shall be permitted to be bare.

2.30.2.2 Size and Rating.

(a) General.

Conductors shall have sufficient ampacity to carry the current for the load as calculated in accordance with Article 2.20 and shall have adequate mechanical strength.

(b) Minimum Size.

The conductors shall not be smaller than 8.0 mm2 (3.2 mm dia.) copper or 14 mm2 aluminum or copper-clad aluminum.

Exception: Conductors supplying only limited loads of a single branch circuit — such as small polyphase power, controlled water heaters, and similar loads — shall not be smaller than 12 AWG hard- drawn copper or equivalent.

(c) Grounded Conductors.

The grounded conductor shall not be less than the minimum size as required by 2.50.2.5(c).

2.30.2.3 Clearances.

Service-drop conductors shall not be readily accessible and shall comply with 2.30.2.3(a) through (d) for services not over 600 volts, nominal.

(a) Above Roofs.

Conductors shall have a vertical clearance of not less than 2 400 mm above the roof surface. The vertical clearance above the roof level shall be maintained for a distance of not less than 900 mm in all directions from the edge of the roof.

Exception No. 1: The area above a roof surface subject to pedestrian or vehicular traffic shall have a vertical clearance from the roof surface in accordance with the clearance requirements of 2.30.2.3(b).

Exception No. 2: Where the voltage between conductors does not exceed 300 and the roof has a slope of 100 mm in 300 mm or greater, a reduction in clearance to 900 mm shall be permitted.

Exception No. 3: Where the voltage between conductors does not exceed 300, a reduction in clearance above only the overhanging portion of the roof to not less than 450 mm shall be permitted if (1) not more than 1 800 mm of service-drop conductors, 1 200 mm horizontally, pass above the roof overhang, and (2) they are terminated at a through-the-roof raceway or approved support.

FPN: See 2.30.2.7 for mast supports.

Exception: The requirement for maintaining the vertical clearance 900 mm from the edge of the roof shall not apply to the final conductor span where the service drop is attached to the side of a building.

(b) Vertical Clearance from Ground.

Service-drop conductors, where not in excess of 600 volts, nominal, shall have the following minimum clearance from final grade:

- (1) 3 000 mm — at the electric service entrance to buildings, also at the lowest point of the drip loop of the building electric entrance, and above areas or sidewalks accessible only to pedestrians, measured from final grade or other accessible surface only for service-drop cables supported on and cabled together with a grounded bare messenger where the voltage does not exceed 150 volts to ground

- (2) 3 600 mm — over residential property and driveways, and those commercial areas not subject to truck traffic where the voltage does not exceed 300 volts to ground

- (3) 4 500 mm — for those areas listed in the 3 600 mm classification where the voltage exceeds 300 volts to ground

- (4) 5 500 mm — over public streets, alleys, roads, parking areas subject to truck traffic, driveways on other than residential property, and other land such as cultivated, grazing, forest, and orchard

(c) Clearance from Building Openings.

See 2.30.1.9.

(d) Clearance from Swimming Pools.

See 6.80.1.8.

2.30.2.5 Point of Attachment.

The point of attachment of the service-drop conductors to a building or other structure shall provide the minimum clearances as specified in 2.30.1.9 and 2.30.2.3. In no case shall this point of attachment be less than 3 000 mm above finished grade.

2.30.2.6 Means of Attachment.

Multiconductor cables used for service drops shall be attached to buildings or other structures by fittings identified for use with service conductors. Open conductors shall be attached to fittings identified for use with service conductors or to noncombustible, nonabsorbent insulators securely attached to the building or other structure.

2.30.2.7 Service Masts as Supports.

Where a service mast is used for the support of service-drop conductors, it shall be of adequate strength or be supported by braces or guys to withstand safely the strain imposed by the service drop. Where raceway-type service masts are used, all raceway fittings shall be identified for use with service masts. Only power service-drop conductors shall be permitted to be attached to a service mast.

2.30.2.8 Supports over Buildings.

Service-drop conductors passing over a roof shall be securely supported by substantial structures. Where practicable, such supports shall be independent of the building.

2.30.3 Underground Service-Lateral Conductors

2.30.3.1 Insulation.

Service-lateral conductors shall be insulated for the applied voltage.

Exception: A grounded conductor shall be permitted to be uninsulated as follows:

- (1) Bare copper used in a raceway.

- (2) Bare copper for direct burial where bare copper is judged to be suitable for the soil conditions.

- (3) Bare copper for direct burial without regard to soil conditions where part of a cable assembly identified for underground use.

- (4) Aluminum or copper-clad aluminum without individual insulation or covering where part of a cable assembly identified for underground use in a raceway or for direct burial.

2.30.3.2 Size and Rating.

(a) General.

Service-lateral conductors shall have sufficient ampacity to carry the current for the load as calculated in accordance with Article 2.20 and shall have adequate mechanical strength.

(b) Minimum Size.

The conductors shall not be smaller than 8.0 mm2 (3.2 mm dia.) copper or 14 mm2 aluminum or copper-clad aluminum.

Exception: Conductors supplying only limited loads of a single branch circuit — such as small polyphase power, controlled water heaters, and similar loads — shall not be smaller than 3.5 mm2 (2.0 mm dia.) copper or 5.5 mm2 (2.6 mm dia.) aluminum or copper-clad aluminum.

(c) Grounded Conductors.

The grounded conductor shall not be less than the minimum size required by 2.50.2.5(c).

2.30.3.3 Protection Against Damage.

Underground service-lateral conductors shall be protected against damage in accordance with 300.5. Service-lateral conductors entering a building shall be installed in accordance with 2.30.1.6 or protected by a raceway wiring method identified in 2.30.4.4.

2.30.3.4 Spliced Conductors.

Service-lateral conductors shall be permitted to be spliced or tapped in accordance with 1.10.1.14, 3.0.1.5(e), 3.0.1.13, and 3.0.1.15.

2.30.4 Service-Entrance Conductors

2.30.4.1 Number of Service-Entrance Conductor Sets.

Each service drop or lateral shall supply only one set of service-entrance conductors.

Exception No. 1: A building shall be permitted to have one set of service-entrance conductors for each service, as defined in 2.30.1.2, run to each occupancy or group of occupancies.

Exception No. 2: Where two to six service disconnecting means in separate enclosures are grouped at one location and supply separate loads from one service drop or lateral in multiple-occupancy building or group of single detached buildings owned/managed/operated by a person or entity, one set of service-entrance conductors shall be permitted to supply each or several such service equipment enclosures.

Exception No. 3: A single-family dwelling unit and a separate structure shall be permitted to have one set of service-entrance conductors run to each from a single service drop or lateral.

Exception No. 4: A two-family dwelling or a multifamily dwelling shall be permitted to have one set of service-entrance conductors installed to supply the circuits covered in 2.10.2.7.

Exception No. 5: One set of service-entrance conductors connected to the supply side of the normal service disconnecting means shall be permitted to supply each or several systems covered by 2.30.6.13(4) or 2.30.6.13(5).

2.30.4.2 Insulation of Service-Entrance Conductors.

Service-entrance conductors entering or on the exterior of buildings or other structures shall be insulated.

Exception: A grounded conductor shall be permitted to be uninsulated as follows:

- (1) Bare copper used in a raceway or part of a service cable assembly.

- (2) Bare copper for direct burial where bare copper is judged to be suitable for the soil conditions.

- (3) Bare copper for direct burial without regard to soil conditions where part of a cable assembly identified for underground use.

- (4) Aluminum or copper-clad aluminum without individual insulation or covering where part of a cable assembly or identified for underground use in a raceway, or for direct burial.

- (5) Bare conductors used in an auxiliary gutter.

2.30.4.3 Minimum Size and Rating.

(a) General.

The ampacity of the service-entrance conductors before the application of any adjustment or correction factors shall not be less than either (a)(1) or (a)(2). Loads shall be determined in accordance with Article 2.20. Ampacity shall be determined from 3.10.1.15. The maximum allowable current of busways shall be that value for which the busway has been listed or labeled.

- (1) The sum of the noncontinuous loads plus 125 percent of continuous loads

- (2) The sum of the noncontinuous load plus the continuous load if the service-entrance conductors terminate in an overcurrent device where both the overcurrent device and its assembly are listed for operation at 100 percent of their rating

(b) Specific Installations.

In addition to the requirements of 2.30.4.3(a), the minimum ampacity for ungrounded conductors for specific installations shall not be less than the rating of the service disconnecting means specified in 2.30.6.10(a) through (d).

(c) Grounded Conductors.

The grounded conductor shall not be less than the minimum size as required by 2.50.2.5(c).

2.30.4.4 Wiring Methods for 600 Volts, Nominal, or Less.

Service-entrance conductors shall be installed in accordance with the applicable requirements of this Code covering the type of wiring method used and shall be limited to the following methods:

- (1) Open wiring on insulators

- (2) Type IGS cable

- (3) Rigid metal conduit

- (4) Intermediate metal conduit

- (5) Electrical metallic tubing

- (6) Electrical nonmetallic tubing (ENT)

- (7) Service-entrance cables

- (8) Wireways

- (9) Busways

- (10) Auxiliary gutters

- (11) Rigid nonmetallic conduit

- (12) Cablebus

- (13) Type MC cable

- (14) Mineral-insulated, metal-sheathed cable

- (15) Flexible metal conduit not over 1 800 mm long or liquidtight flexible metal conduit not over 1 800 mm long between raceways, or between raceway and service equipment, with equipment bonding jumper routed with the flexible metal conduit or the liquidtight flexible metal conduit according to the provisions of 2.50.5.13(a), (b), (c), and (e)

- (16) Liquidtight flexible nonmetallic conduit

2.30.4.5 Cable Trays.

Cable tray systems shall be permitted to support service-entrance conductors. Cable trays used to support service-entrance conductors shall contain only service-entrance conductors.

Exception: Conductors other than service-entrance conductors shall be permitted to be installed in a cable tray with service-entrance conductors, provided a solid fixed barrier of a material compatible with the cable tray is installed to separate the service-entrance conductors from other conductors installed in the cable tray.

2.30.4.7 Spliced Conductors.

Service-entrance conductors shall be permitted to be spliced or tapped in accordance with 1.10.1.14, 3.0.1.5(e), 3.0.1.13, and 3.0.1.15.

2.30.4.10 Protection Against Physical Damage — Underground.

Underground service-entrance conductors shall be protected against physical damage in accordance with 3.0.1.5.

2.30.4.11 Protection of Open Conductors and Cables Against Damage - Above Ground.

Service-entrance conductors installed above ground shall be protected against physical damage as specified in 2.30.4.11(a) or (b).

(a) Service Cables.

Service cables, where subject to physical damage, shall be protected by any of the following:

- (1) Rigid metal conduit

- (2) Intermediate metal conduit

- (3) Schedule 80 rigid nonmetallic conduit

- (4) Electrical metallic tubing

- (5) Other approved means

(b) Other Than Service Cable.

Individual open conductors and cables other than service cables shall not be installed within 3 000 mm of grade level or where exposed to physical damage.

Exception: Type MI and Type MC cable shall be permitted within 3 000 mm of grade level where not exposed to physical damage or where protected in accordance with 3.0.1.5(d).

2.30.4.12 Mounting Supports.

Cables or individual open service conductors shall be supported as specified in 2.30.4.12(a), (b), or (c).

(a) Service Cables.

Service cables shall be supported by straps or other approved means within 300 mm of every service head, gooseneck, or connection to a raceway or enclosure and at intervals not exceeding 750 mm.

(b) Other Cables.

Cables that are not approved for mounting in contact with a building or other structure shall be mounted on insulating supports installed at intervals not exceeding 4 500 mm and in a manner that maintains a clearance of not less than 50 mm from the surface over which they pass.

(c) Individual Open Conductors.

Individual open conductors shall be installed in accordance with Table 2.30.4.12(c). Where exposed to the weather, the conductors shall be mounted on insulators or on insulating supports attached to racks, brackets, or other approved means. Where not exposed to the weather, the conductors shall be mounted on glass or porcelain knobs.

| Maximum Volts | Maximum Distance Between Supports (m) | Minimum Clearance | |

|---|---|---|---|

| Between Conductors (mm) | From Surface (mm) | ||

| 600 | 2.7 | 150 | 50 |

| 600 | 4.5 | 300 | 50 |

| 300 | 1.4 | 75 | 50 |

| 600* | 1.4* | 65* | 25* |

| *Where not exposed to weather. | |||

2.30.4.13 Individual Conductors Entering Buildings or Other Structures.

Where individual open conductors enter a building or other structure, they shall enter through roof bushings or through the wall in an upward slant through individual, noncombustible, nonabsorbent insulating tubes. Drip loops shall be formed on the conductors before they enter the tubes.

2.30.4.14 Raceways to Drain.

Where exposed to the weather, raceways enclosing service-entrance conductors shall be raintight and arranged to drain. Where embedded in masonry, raceways shall be arranged to drain.

Exception: As permitted in 3.48.2.3(1).

2.30.4.15 Overhead Service Locations.

(a) Raintight Service Head.

Service raceways shall be equipped with a raintight service head at the point of connection to service-drop conductors.

(b) Service Cable Equipped with Raintight Service Head or Gooseneck.

Service cables shall be equipped with a raintight service head.

Exception: Type SE cable shall be permitted to be formed in a gooseneck and taped with a self-sealing weather-resistant thermoplastic.

(c) Service Heads and Goosenecks Above Service-Drop Attachment.

Service heads and goosenecks in service-entrance cables shall be located above the point of attachment of the service-drop conductors to the building or other structure.

Exception: Where it is impracticable to locate the service head or gooseneck above the point of attachment, the service head or gooseneck location shall be permitted not farther than 600 mm from the point of attachment.

(d) Secured.

Service cables shall be held securely in place.

(e) Separately Bushed Openings.

Service heads shall have conductors of different potential brought out through separately bushed openings.

Exception: For jacketed multiconductor service cable without splice.

(f) Drip Loops.

Drip loops shall be formed on individual conductors. To prevent the entrance of moisture, service-entrance conductors shall be connected to the service-drop conductors either (1) below the level of the service head or (2) below the level of the termination of the service-entrance cable sheath.

(g) Arranged That Water Will Not Enter Service Raceway or Equipment.

Service-drop conductors and service-entrance conductors shall be arranged so that water will not enter service raceway or equipment.

2.30.4.17 Service Conductor with the Higher Voltage to Ground.

On a 4-wire, delta-connected service where the midpoint of one phase winding is grounded, the service conductor having the higher phase voltage to ground shall be durably and permanently marked by an outer finish that is orange in color, or by other effective means, at each termination or junction point.

2.30.5 Service Equipment — General

2.30.5.1 Service Equipment — Enclosed or Guarded.

Energized parts of service equipment shall be enclosed as specified in 2.30.5.1(a) or guarded as specified in 2.30.5.1(b).

(a) Enclosed.

Energized parts shall be enclosed so that they will not be exposed to accidental contact or shall be guarded as in 2.30.5.1(b).

(b) Guarded.

Energized parts that are not enclosed shall be installed on a switchboard, panelboard, or control board and guarded in accordance with 1.10.1.18 and 1.10.2.2. Where energized parts are guarded as provided in 1.10.2.2(a)(1) and (a)(2), a means for locking or sealing doors providing access to energized parts shall be provided.

2.30.5.5 Marking.

Service equipment rated at 600 volts or less shall be marked to identify it as being suitable for use as service equipment. Individual meter socket enclosures shall not be considered service equipment.

2.30.6 Service Equipment — Disconnecting Means

2.30.6.1 General.

Means shall be provided to disconnect all conductors in a building or other structure from the service-entrance conductors.

(a) Location. The service disconnecting means shall be installed in accordance with 2.30.6.1(a)(1), (a)(2), and (a)(3).

- (1) Readily Accessible Location. The service disconnecting means shall be installed at a readily accessible location of a building or a structure. For a building, the service disconnecting means shall be installed either at the outside wall or inside nearest the point of entrance of the service conductors to the building.

- (2) Bathrooms. Service disconnecting means shall not be installed in bathrooms.

- (3) Remote Control. Where a remote control device(s) is used to actuate the service disconnecting means, the service disconnecting means shall be located in accordance with 2.30.6.1(a)(1).

(b) Marking. Each service disconnect shall be permanently marked to identify it as a service disconnect.

(c) Suitable for Use. Each service disconnecting means shall be suitable for the prevailing conditions. Service equipment installed in hazardous (classified) locations shall comply with the requirements of Articles 5.0 through 5.17.

2.30.6.2 Maximum Number of Disconnects.

(a) General. The service disconnecting means for each service permitted by 2.30.1.2, or for each set of service-entrance conductors permitted by 2.30.4.1, Exception Nos. 1, 3, 4, or 5, shall consist of not more than six switches or sets of circuit breakers, or a combination of not more than six switches and sets of circuit breakers, mounted in a single enclosure, in a group of separate enclosures, or in or on a switchboard. There shall be not more than six sets of disconnects per service grouped in any one location. For the purpose of this section, disconnecting means used solely for power monitoring equipment, transient voltage surge suppressors, or the control circuit of the ground-fault protection system or power-operable service disconnecting means, installed as part of the listed equipment, shall not be considered a service disconnecting means.

(b) Single-Pole Units. Two or three single-pole switches or breakers, capable of individual operation, shall be permitted on multiwire circuits, one pole for each ungrounded conductor, as one multipole disconnect, provided they are equipped with handle ties or a master handle to disconnect all conductors of the service with no more than six operations of the hand.

FPN: See 4.8.3.7(a) for service equipment in panelboards, and see 4.30.8.4 for service equipment in motor control centers.

2.30.6.3 Grouping of Disconnects.

(a) General. The two to six disconnects as permitted in 2.30.6.2 shall be grouped. Each disconnect shall be marked to indicate the load served.

Exception: One of the two to six service disconnecting means permitted in 2.30.6.2, where used only for a water pump also intended to provide fire protection, shall be permitted to be located remote from the other disconnecting means.

(b) Additional Service Disconnecting Means. The one or more additional service disconnecting means for fire pumps, emergency systems, legally required standby, or optional standby services permitted by 2.30.1.2 shall be installed remote from the one to six service disconnecting means for normal service to minimize the possibility of simultaneous interruption of supply.

(c) Access to Occupants. In a multiple-occupancy building, each occupant shall have access to the occupant’s service disconnecting means.

Exception: In a multiple-occupancy building where electric service and electrical maintenance are provided by the building management and where these are under continuous building management supervision, the service disconnecting means supplying more than one occupancy shall be permitted to be accessible to authorized management personnel only.

2.30.6.5 Simultaneous Opening of Poles.

Each service disconnect shall simultaneously disconnect all ungrounded service conductors that it controls from the premises wiring system.

2.30.6.6 Disconnection of Grounded Conductor.

Where the service disconnecting means does not disconnect the grounded conductor from the premises wiring, other means shall be provided for this purpose in the service equipment. A terminal or bus to which all grounded conductors can be attached by means of pressure connectors shall be permitted for this purpose. In a multisection switchboard, disconnects for the grounded conductor shall be permitted to be in any section of the switchboard, provided any such switchboard section is marked.

2.30.6.7 Manually or Power Operable.

The service disconnecting means for ungrounded service conductors shall consist of one of the following:

(1) A manually operable switch or circuit breaker equipped with a handle or other suitable operating means

(2) A power-operated switch or circuit breaker, provided the switch or circuit breaker can be opened by hand in the event of a power supply failure

2.30.6.8 Indicating.

The service disconnecting means shall plainly indicate whether it is in the open or closed position.

2.30.6.10 Rating of Service Disconnecting Means.

The service disconnecting means shall have a rating not less than the load to be carried, determined in accordance with Article 2.20. In no case shall the rating be lower than specified in 2.30.6.10(a), (b), (c), or (d).

(a) One-Circuit Installation. For installations to supply only limited loads of a single branch circuit, the service disconnecting means shall have a rating of not less than 15 amperes.

(b) Two-Circuit Installations. For installations consisting of not more than two 2-wire branch circuits, the service disconnecting means shall have a rating of not less than 30 amperes.

(c) One-Family Dwelling. For a one-family dwelling, the service disconnecting means shall have a rating of not less than 100 amperes, 3-wire.

(d) All Others. For all other installations, the service disconnecting means shall have a rating of not less than 60 amperes.

2.30.6.11 Combined Rating of Disconnects.

Where the service disconnecting means consists of more than one switch or circuit breaker, as permitted by 2.30.6.2, the combined ratings of all the switches or circuit breakers used shall not be less than the rating required by 2.30.6.10.

2.30.6.12 Connection to Terminals.

The service conductors shall be connected to the service disconnecting means by pressure connectors, clamps, or other approved means. Connections that depend on solder shall not be used.

2.30.6.13 Equipment Connected to the Supply Side of Service Disconnect.

Only the following equipment shall be permitted to be connected to the supply side of the service disconnecting means:

(1) Cable limiters or other current-limiting devices

(2) Meters and meter sockets nominally rated not in excess of 600 volts, provided all metal housings and service enclosures are grounded

(3) Meter disconnect switches nominally rated not in excess of 600 volts that have a short-circuit current rating equal to or greater than the available short circuit current, provided all metal housings and service enclosures are grounded

(4) Instrument transformers (current and voltage), impedance shunts, load management devices, and arresters

(5) Taps used only to supply load management devices, circuits for standby power systems, fire pump equipment, and fire and sprinkler alarms, if provided with service equipment and installed in accordance with requirements for service-entrance conductors

(6) Solar photovoltaic systems, fuel cell systems, or interconnected electric power production sources

(7) Control circuits for power-operable service disconnecting means, if suitable overcurrent protection and disconnecting means are provided

(8) Ground-fault protection systems or transient voltage surge suppressors, where installed as part of listed equipment, if suitable overcurrent protection and disconnecting means are provided

(9) Fusible disconnect switch or circuit breaker as deemed necessary. This equipment is considered as additional protection, while the next disconnecting means mentioned in 2.30.6.1(a)(1) shall still be considered as the service equipment.

2.30.7 Service Equipment — Overcurrent Protection

2.30.7.1 Where Required.

Each ungrounded service conductor shall have overload protection.

(a) Ungrounded Conductor. Such protection shall be provided by an overcurrent device in series with each ungrounded service conductor that has a rating or setting not higher than the allowable ampacity of the conductor. A set of fuses shall be considered all the fuses required to protect all the ungrounded conductors of a circuit. Single-pole circuit breakers, grouped in accordance with 2.30.6.2(b), shall be considered as one protective device.

Exception No. 1: For motor-starting currents, ratings that conform with 4.30.4.2, 4.30.5.2, and 4.30.5.3 shall be permitted.

Exception No. 2: Fuses and circuit breakers with a rating or setting that conforms with 2.40.1.4(b) or (c) and 2.40.1.6 shall be permitted.

Exception No. 3: Two to six circuit breakers or sets of fuses shall be permitted as the overcurrent device to provide the overload protection. The sum of the ratings of the circuit breakers or fuses shall be permitted to exceed the ampacity of the service conductors, provided the calculated load does not exceed the ampacity of the service conductors.

Exception No. 4: Overload protection for fire pump supply conductors shall conform with 6.95.1.4(b)(1).

Exception No. 5: Overload protection for 120/240-volt, 3-wire, single-phase dwelling services shall be permitted in accordance with the requirements of 3.10.1.15(b)(6).

(b) Not in Grounded Conductor. No overcurrent device shall be inserted in a grounded service conductor except a circuit breaker that simultaneously opens all conductors of the circuit.

2.30.7.2 Location.

The service overcurrent device shall be an integral part of the service disconnecting means or shall be located immediately adjacent thereto.

2.30.7.3 Locked Service Overcurrent Devices.

Where the service overcurrent devices are locked or sealed or are not readily accessible to the occupant, branch-circuit overcurrent devices shall be installed on the load side, shall be mounted in a readily accessible location, and shall be of lower ampere rating than the service overcurrent device.

2.30.7.4 Protection of Specific Circuits.

Where necessary to prevent tampering, an automatic overcurrent device that protects service conductors supplying only a specific load, such as a water heater, shall be permitted to be locked or sealed where located so as to be accessible.

2.30.7.5 Relative Location of Overcurrent Device and Other Service Equipment.

The overcurrent device shall protect all circuits and devices.

Exception No. 1: The service switch shall be permitted on the supply side.

Exception No. 2: High-impedance shunt circuits, surge arresters, surge-protective capacitors, and instrument transformers (current and voltage) shall be permitted to be connected and installed on the supply side of the service disconnecting means as permitted in 2.30.6.13.

Exception No. 3: Circuits for load management devices shall be permitted to be connected on the supply side of the service overcurrent device where separately provided with overcurrent protection.

Exception No. 4: Circuits used only for the operation of fire alarm, other protective signaling systems, or the supply to fire pump equipment shall be permitted to be connected on the supply side of the service overcurrent device where separately provided with overcurrent protection.

Exception No. 5: Meters nominally rated not in excess of 600 volts shall be permitted, provided all metal housings and service enclosures are grounded.

Exception No. 6: Where service equipment is power operable, the control circuit shall be permitted to be connected ahead of the service equipment if suitable overcurrent protection and disconnecting means are provided.

2.30.7.6 Ground-Fault Protection of Equipment.

Ground-fault protection of equipment shall be provided for solidly grounded wye electrical services of more than 150 volts to ground but not exceeding 600 volts phase-to-phase for each service disconnect rated 1000 amperes or more. The grounded conductor for the solidly grounded wye system shall be connected directly to ground without inserting any resistor or impedance device.

The rating of the service disconnect shall be considered to be the rating of the largest fuse that can be installed or the highest continuous current trip setting for which the actual overcurrent device installed in a circuit breaker is rated or can be adjusted.

Exception No. 1: The ground-fault protection provisions of this section shall not apply to a service disconnect for a continuous industrial process where a nonorderly shutdown will introduce additional or increased hazards.

Exception No. 2: The ground-fault protection provisions of this section shall not apply to fire pumps.

(a) Setting. The ground-fault protection system shall operate to cause the service disconnect to open all ungrounded conductors of the faulted circuit. The maximum setting of the ground-fault protection shall be 1200 amperes, and the maximum time delay shall be one second for ground-fault currents equal to or greater than 3000 amperes.

(b) Fuses. If a switch and fuse combination is used, the fuses employed shall be capable of interrupting any current higher than the interrupting capacity of the switch during a time that the ground-fault protective system will not cause the switch to open.

(c) Performance Testing. The ground-fault protection system shall be performance tested when first installed on site. The test shall be conducted in accordance with instructions that shall be provided with the equipment. A written record of this test shall be made and shall be available to the authority having jurisdiction.

FPN No. 1: Ground-fault protection that functions to open the service disconnect affords no protection from faults on the line side of the protective element. It serves only to limit damage to conductors and equipment on the load side in the event of an arcing ground fault on the load side of the protective element.

FPN No. 2: This added protective equipment at the service equipment may make it necessary to review the overall wiring system for proper selective overcurrent protection coordination. Additional installations of ground-fault protective equipment may be needed on feeders and branch circuits where maximum continuity of electrical service is necessary.

FPN No. 3: Where ground-fault protection is provided for the service disconnect and interconnection is made with another supply system by a transfer device, means or devices may be needed to ensure proper ground-fault sensing by the ground-fault protection equipment.

FPN No. 4: See 5.17.2.8(a) for information on where an additional step of ground fault protection is required for hospitals and other buildings with critical areas or life support equipment.

2.30.8 Services Exceeding 600 Volts, Nominal

2.30.8.1 General.

Service conductors and equipment used on circuits exceeding 600 volts, nominal, shall comply with all the applicable provisions of the preceding sections of this article and with the following sections that supplement or modify the preceding sections. In no case shall the provisions of Part 2.30.8 apply to equipment on the supply side of the service point.

FPN: For clearances of conductors of over 600 volts, nominal, see ANSI C2-2002, National Electrical Safety Code.

2.30.8.3 Service-Entrance Conductors.

Service-entrance conductors to buildings or enclosures shall be installed to conform to 2.30.8.3(a) and (b).

(a) Conductor Size. Service-entrance conductors shall not be smaller than 14 mm 2 unless in multiconductor cable. Multiconductor cable shall not be smaller than 8.0 mm 2 (3.2 mm dia.).

(b) Wiring Methods. Service-entrance conductors shall be installed by one of the wiring methods covered in 3.0.2.7 and 3.0.2.20.

2.30.8.5 Isolating Switches.

(a) Where Required. Where oil switches or air, oil, vacuum, or sulfur hexafluoride circuit breakers constitute the service disconnecting means, an isolating switch with visible break contacts shall be installed on the supply side of the disconnecting means and all associated service equipment.

Exception: An isolating switch shall not be required where the circuit breaker or switch is mounted on removable truck panels or metal- enclosed switchgear units where both of the following conditions apply:

- (1) Cannot be opened unless the circuit is disconnected.

- (2) Where all energized parts are automatically disconnected when the circuit breaker or switch is removed from the normal operating position.

(b) Fuses as Isolating Switch. Where fuses are of the type that can be operated as a disconnecting switch, a set of such fuses shall be permitted as the isolating switch.

(c) Accessible to Licensed electrical practitioner or non licensed electrical practitioner under the supervision of a licensed electrical practitioner Only. The isolating switch shall be accessible to licensed electrical practitioner or non licensed electrical practitioner under the supervision of a licensed electrical practitioner only.

(d) Grounding Connection. Isolating switches shall be provided with a means for readily connecting the load side conductors to ground when disconnected from the source of supply. A means for grounding the load side conductors shall not be required for any duplicate isolating switch installed and maintained by the electric supply company.

2.30.8.6 Disconnecting Means.

(a) Location. The service disconnecting means shall be located in accordance with 2.30.6.1.

(b) Type. Each service disconnect shall simultaneously disconnect all ungrounded service conductors that it controls and shall have a fault-closing rating that is not less than the maximum short-circuit current available at its supply terminals. Where fused switches or separately mounted fuses are installed, the fuse characteristics shall be permitted to contribute to the fault-closing rating of the disconnecting means.

(c) Remote Control. For multibuilding, industrial installations under single management, the service disconnecting means shall be permitted to be located at a separate building or structure. In such cases, the service disconnecting means shall be permitted to be electrically operated by a readily accessible, remote-control device.

2.30.8.7 Overcurrent Devices as Disconnecting Means.

Where the circuit breaker or alternative for it, as specified in 2.30.8.9 for service overcurrent devices, meets the requirements specified in 2.30.8.6, they shall constitute the service disconnecting means.

2.30.8.9 Protection Requirements.

A short-circuit protective device shall be provided on the load side of, or as an integral part of, the service disconnect, and shall protect all ungrounded conductors that it supplies. The protective device shall be capable of detecting and interrupting all values of current, in excess of its trip setting or melting point, that can occur at its location. A fuse rated in continuous amperes not to exceed three times the ampacity of the conductor, or a circuit breaker with a trip setting of not more than six times the ampacity of the conductors, shall be considered as providing the required short- circuit protection.

FPN: See Table 3.10.1.67 through Table 3.10.1.86 for ampacities of conductors rated 2001 volts and above. Overcurrent devices shall conform to 2.30.8.9(a) and (b).

(a) Equipment Type. Equipment used to protect service-entrance conductors shall meet the requirements of Part 4.90.2.

(b) Enclosed Overcurrent Devices. The restriction to 80 percent of the rating for an enclosed overcurrent device for continuous loads shall not apply to overcurrent devices installed in systems operating at over 600 volts.

2.30.8.10 Surge Arresters (Lightning Arresters).

Surge arresters installed in accordance with the requirements of Article 2.80 shall be permitted on each ungrounded overhead service conductor.

2.30.8.11 Service Equipment — General Provisions.

Service equipment, including instrument transformers, shall conform to Part 4.90.1.

2.30.8.12 Metal-Enclosed Switchgear.

Metal-enclosed switchgear shall consist of a substantial metal structure and a sheet metal enclosure. Where installed over a combustible floor, suitable protection thereto shall be provided.

2.30.8.13 Over 35,000 Volts.

Where the voltage exceeds 35,000 volts between conductors that enter a building, they shall terminate in a metal-enclosed switchgear compartment or a vault conforming to the requirements of 4.50.3.1 through 4.50.3.8.

Other Pages in this Category: Chapter 2. Wiring and Protection

<DynamicPageList> category = Philippine Electrical Code 2017 Part 1/Chapter 2. Wiring and Protection count = 5 order = ascending addfirstcategorydate = false </DynamicPageList>